WARNING!

To reduce the risk of injury, do not rely on the brake as a safety feature. Always wait until the blade stops completely before allowing anything near the blade.

Electric Brake

The electric brake engages when the trigger is released, causing the blade to stop and allowing you to proceed with your work. Generally the saw blade stops in four to five seconds. However, there may be a delay between the time the trigger is released and the time the brake engages. Occasionally the brake may miss completely. If the brake misses fre- quently, the saw needs servicing by an authorized MILWAUKEE ser- vice station. The brake is not a substitute for the guards, so it is essential to always wait for the blade to stop completely before removing the blade from the kerf. The correct brush grade must be used for proper operation of the brake. Use only identical MILWAUKEE replacement brushes when servicing the tool.

Cutting the Kerf Plate Slot

The tool is shipped with the kerf plate installed; never attempt to make a cut without the plate installed. The kerf plate is NOT

When cutting a kerf slot, be sure to use the blade you intend to use for your work since blades have different widths that affect the kerf. When changing from a thick blade to a thinner one, you may want to purchase a new kerf plate and cut a new kerf slot. Also, bevel cuts require a different kerf slot than miter cuts, so always be sure to cut a new slot for bevel cuts. Cut the kerf slot following the procedure below.

1.Make sure that the slide rail lock is loose and that the saw head moves freely back and forth on the slide rails.

2.Raise saw head and pull it out OVER the kerf plate WITHOUT cutting.

3.Start the motor. Wait a few seconds for the blade to reach full speed.

4.Press down on the saw head. To help prevent damaging the kerf plate, gently and slowly lower the saw head to the full depth of cut (the point where the saw head will not lower any further). When the cut is complete, release the trigger. WAIT FOR THE BLADE TO STOP COMPLETELY before gently raising the saw head.

5.Push saw through the cut.

Making a Chop Cut (Fig. 8)

The Magnum® Slide Compound Miter saw can be used to make chop cuts (cuts not requiring the use of the slide mechanism). Cut workpieces with chop cuts whenever possible. A chop cut is always faster and easier to make than a sliding cut.

Fig. 8

1

2

3

1.Slide the saw head back on the slide rails so that the blade is closest to the fence (1).

2.Tighten the slide rail lock (2).

3.Plug in the tool. Raise the saw head completely.

4.Select the desired angles following the steps in "Adjusting the Miter Angle" and "Adjusting the Bevel Angle".

5.Place the workpiece on the turntable and line up the cut.

6.Support the workpiece using any of the methods described in "Sup- port the Workpiece Properly".

7.Start the motor. Wait a few seconds for the blade to reach full speed. Then gently lower the saw head into the workpiece all the way through the cut (3).

8.Always allow the saw to do the work. Forcing the tool may stall or overheat the motor.

9.After the cut is complete, release the trigger and wait for the blade to stop completely. Then gently raise the saw head and remove the workpiece. Always unplug the tool before retrieving loose

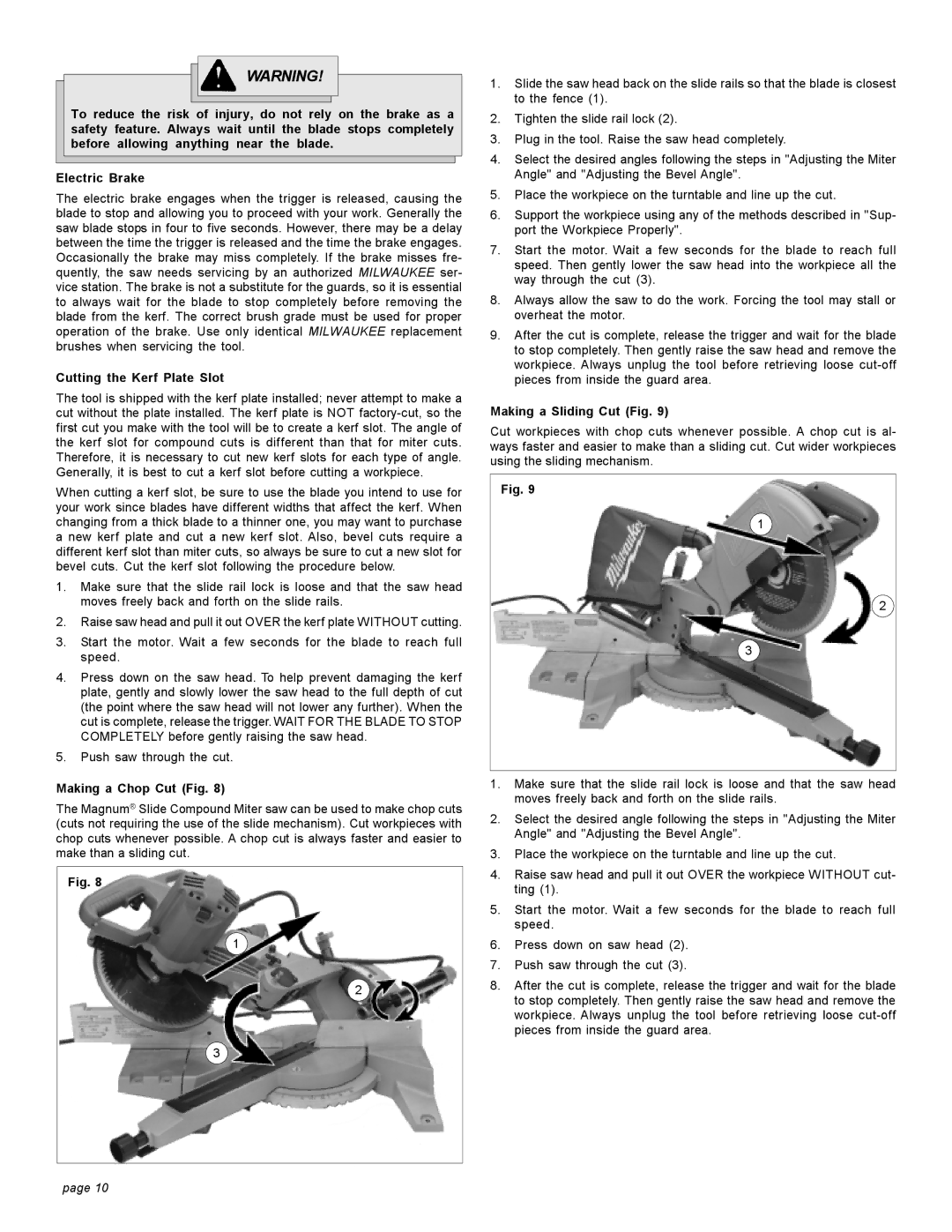

Making a Sliding Cut (Fig. 9)

Cut workpieces with chop cuts whenever possible. A chop cut is al- ways faster and easier to make than a sliding cut. Cut wider workpieces using the sliding mechanism.

Fig. 9

1

2

3

1.Make sure that the slide rail lock is loose and that the saw head moves freely back and forth on the slide rails.

2.Select the desired angle following the steps in "Adjusting the Miter Angle" and "Adjusting the Bevel Angle".

3.Place the workpiece on the turntable and line up the cut.

4.Raise saw head and pull it out OVER the workpiece WITHOUT cut- ting (1).

5.Start the motor. Wait a few seconds for the blade to reach full speed.

6.Press down on saw head (2).

7.Push saw through the cut (3).

8.After the cut is complete, release the trigger and wait for the blade to stop completely. Then gently raise the saw head and remove the workpiece. Always unplug the tool before retrieving loose

page 10