TOOL ASSEMBLY

WARNING!

To reduce the risk of injury, always unplug tool before attaching or removing accessories or making adjustments. Use only specifically recommended accessories. Others may be hazardous.

Mounting the Miter Saw

To prevent the tool from sliding, falling or tipping during operation, the saw can be mounted to a supporting surface such as a level, sturdy work table or bench. Position the saw and workbench to allow adequate room for

Installing the Clamp Handle

The clamp handle locks the selected miter angle. The tool is shipped with the handle unassembled. To install the handle, thread it clockwise into the tool. To tighten the handle and lock the angle, turn the handle clock- wise. To loosen and unlock, turn it counterclockwise.

Installing Dust Bag or Vacuum Hose

A dust bag is provided to collect sawdust. To install the dust bag, push the dust bag onto the dust ejection port. This port is also designed to accept a standard workshop vacuum hose. To collect sawdust directly into a vacuum cleaner, attach the vacuum cleaner hose to the dust ejection port and turn it on before cutting.

Raising and Lowering the Saw Head

The saw head locks down for transporting and storing the tool. The tool is shipped with the saw head locked down. To unlock it, press and hold down the saw head and simultaneously pull out the lock pin. To lock the saw head, press and hold down the saw head and then push in the lock pin.

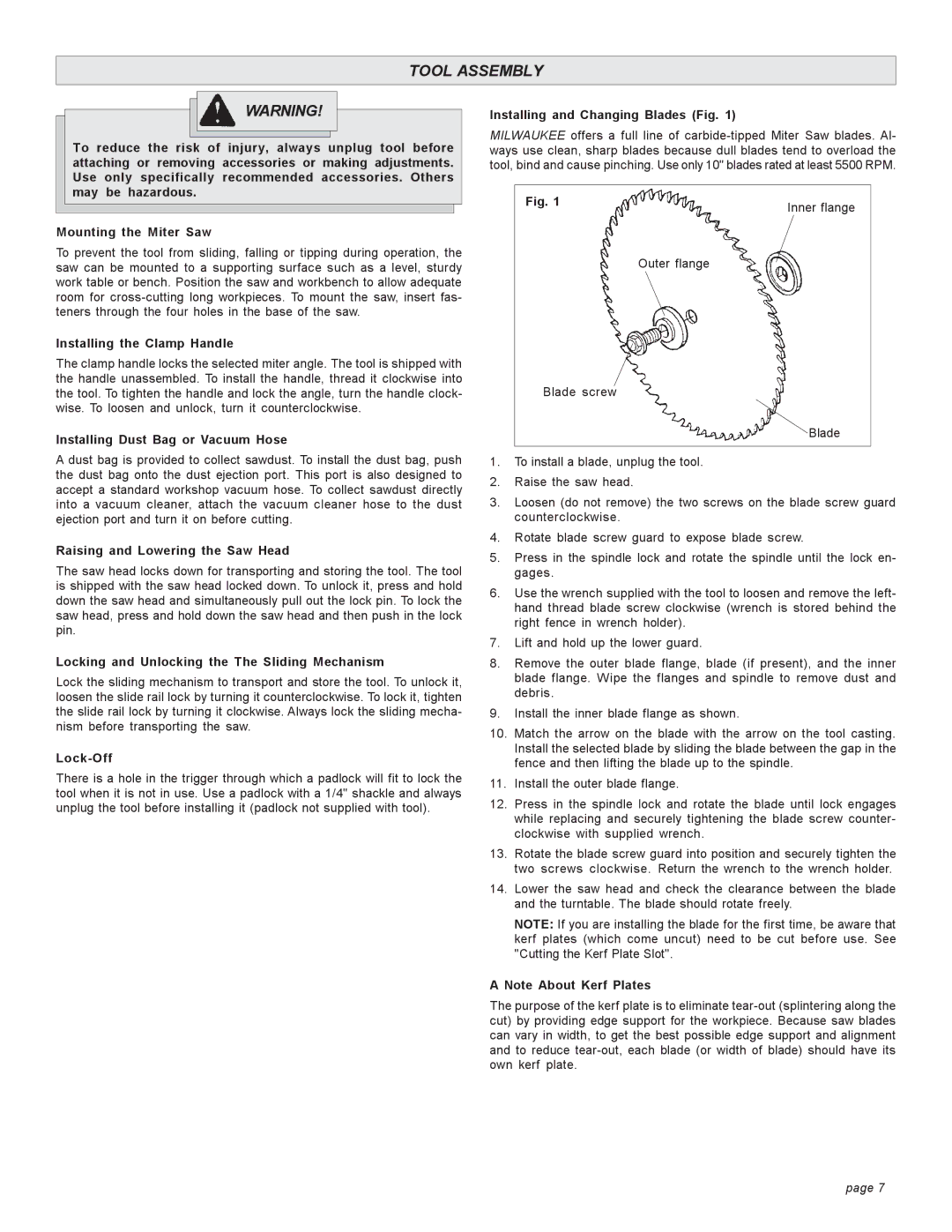

Installing and Changing Blades (Fig. 1)

MILWAUKEE offers a full line of

Fig. 1 | Inner flange |

| |

| Outer flange |

Blade screw

![]() Blade

Blade

1.To install a blade, unplug the tool.

2.Raise the saw head.

3.Loosen (do not remove) the two screws on the blade screw guard counterclockwise.

4.Rotate blade screw guard to expose blade screw.

5.Press in the spindle lock and rotate the spindle until the lock en- gages.

6.Use the wrench supplied with the tool to loosen and remove the left- hand thread blade screw clockwise (wrench is stored behind the right fence in wrench holder).

7.Lift and hold up the lower guard.

Locking and Unlocking the The Sliding Mechanism

Lock the sliding mechanism to transport and store the tool. To unlock it, loosen the slide rail lock by turning it counterclockwise. To lock it, tighten the slide rail lock by turning it clockwise. Always lock the sliding mecha- nism before transporting the saw.

Lock-Off

There is a hole in the trigger through which a padlock will fit to lock the tool when it is not in use. Use a padlock with a 1/4" shackle and always unplug the tool before installing it (padlock not supplied with tool).

8.Remove the outer blade flange, blade (if present), and the inner blade flange. Wipe the flanges and spindle to remove dust and debris.

9.Install the inner blade flange as shown.

10.Match the arrow on the blade with the arrow on the tool casting. Install the selected blade by sliding the blade between the gap in the fence and then lifting the blade up to the spindle.

11.Install the outer blade flange.

12.Press in the spindle lock and rotate the blade until lock engages while replacing and securely tightening the blade screw counter- clockwise with supplied wrench.

13.Rotate the blade screw guard into position and securely tighten the two screws clockwise. Return the wrench to the wrench holder.

14.Lower the saw head and check the clearance between the blade and the turntable. The blade should rotate freely.

NOTE: If you are installing the blade for the first time, be aware that kerf plates (which come uncut) need to be cut before use. See "Cutting the Kerf Plate Slot".

A Note About Kerf Plates

The purpose of the kerf plate is to eliminate

page 7