APPLICATIONS

Recommended Materials and Applications

The following materials can be cut with the slide compound miter saw. There are many types of saw blades available. Always use the proper blade for the particular material and application.

Wood

solid wood, plywood, particle board, MDF (medium density fiber- board), HDF (high density fiberboard), melamine laminated particle board, formica laminates, hardboard (masonite).

Plastics

PVC, CPVC, ABS, solid surfacing materials (such as Corian®), and other plastic materials.

Nonferrous Metals

aluminum, brass, copper, and other

WARNING!

Do not cut stone, brick, concrete, or ferrous metals (iron, steel, stainless steel, or alloys of these metals) with this saw .

Do not use abrasive wheels with this saw.

Dust created by cutting these materials and/or using abra- sive

Cutting

Cutting Round (Cylindrical) Materials

"V" shaped blocks can be used to support round materials like closet rod and plastic pipe.

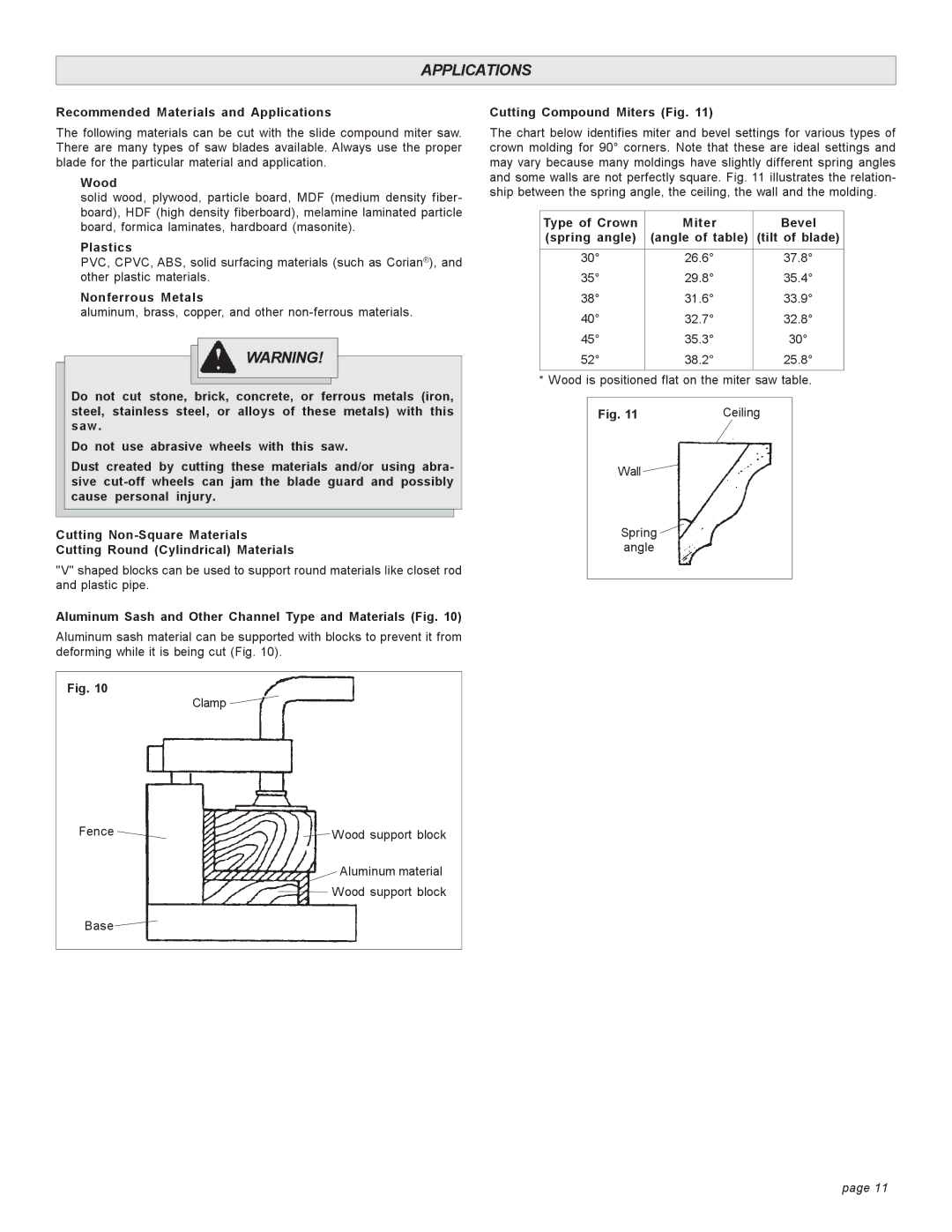

Aluminum Sash and Other Channel Type and Materials (Fig. 10)

Aluminum sash material can be supported with blocks to prevent it from deforming while it is being cut (Fig. 10).

Fig. 10

Clamp

Fence | Wood support block |

Aluminum material

Wood support block

Base

Cutting Compound Miters (Fig. 11)

The chart below identifies miter and bevel settings for various types of crown molding for 90° corners. Note that these are ideal settings and may vary because many moldings have slightly different spring angles and some walls are not perfectly square. Fig. 11 illustrates the relation- ship between the spring angle, the ceiling, the wall and the molding.

Type of Crown | Miter | Bevel |

(spring angle) | (angle of table) | (tilt of blade) |

|

|

|

30° | 26.6° | 37.8° |

35° | 29.8° | 35.4° |

38° | 31.6° | 33.9° |

40° | 32.7° | 32.8° |

45° | 35.3° | 30° |

52° | 38.2° | 25.8° |

|

|

|

* Wood is positioned flat on the miter saw table.

Fig. 11 | Ceiling |

Wall

Spring

angle

page 11