Gas Pressure -

Tables 4, 5 and 6 show the appliances' gas pressure requirements.

Inlet Gas Supply Pressure

(all models)

Fuel # |

|

| Minimum | Maximum | |

|

|

|

|

|

|

Natural Gas |

| 5.0" WC | 10.5" WC | ||

| (1.24 kPa) | (2.61 kPa) | |||

|

|

| |||

Propane |

|

| 11.0" WC | 13.0" WC | |

|

| (2.74 kPa) | (3.23 kPa) | ||

|

|

| |||

|

|

|

|

|

|

Table 4 |

|

|

|

|

|

|

|

| |||

Manifold Gas Supply Pressure | |||||

|

| (millivolt models) | |||

|

|

|

|

|

|

Fuel # |

|

| Low |

| High |

|

|

|

| ||

Natural | (Lo) 2.2" WC |

| (Hi) 3.5" WC | ||

Gas |

|

| (.55 kPa) |

| (.87 kPa) |

|

|

|

| ||

Propane | (Lo) 6.3" WC |

| (Hi) 10.0" WC | ||

| (1.57 kPa) |

| (2.49 kPa) | ||

|

|

| |||

|

|

|

|

|

|

Table 5 |

|

|

|

|

|

At the time of installation, it must be determined if the appliance needs to be derated. Contact your local gas supplier for deration requirements for your area.

Deration - At higher elevations, the amount of BTU fuel value delivered must be reduced by either using gas that has been derated by the gas company or by changing the burner orifice to a smaller size as regulated by the local authorities having jurisdiction and by the (USA) National Fuel Gas Code NFPA 54/ANSI Z223.1 - latest edition or, in Canada, the

Burner Orifice Sizes

Elevation 0-4500 feet ( 0-1372 meters)

Model | Natural | Propane | |

Gas | Gas | ||

Series | |||

drill size | drill size (inches) | ||

| (inches) |

| |

|

|

| |

#45 (.082") * | 1.2 mm (.048") * | ||

39L66 • | 99K78 • | ||

|

|

| |

#44 (.086") * | #55 (.052") * | ||

60J80 • | 19L52 • | ||

|

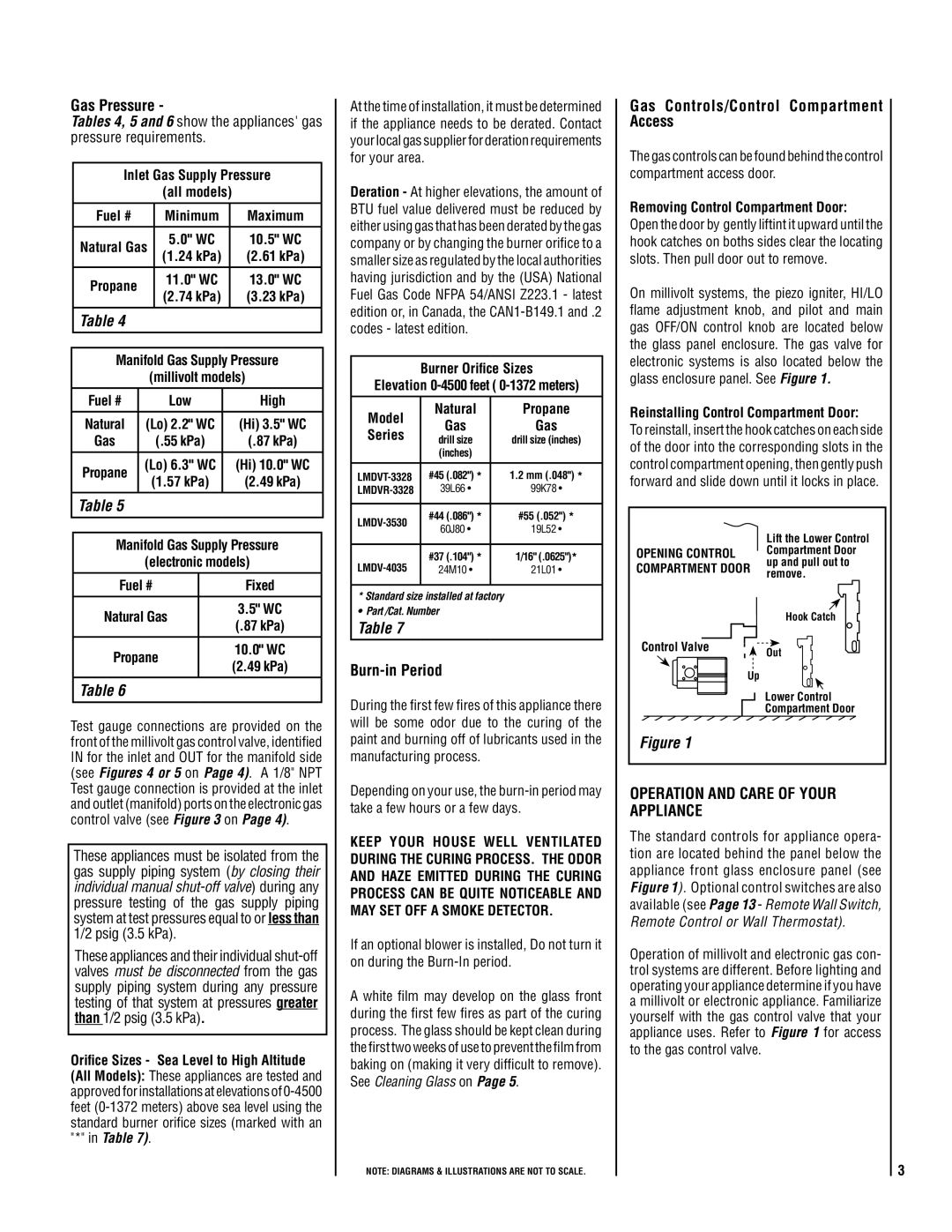

Gas Controls/Control Compartment Access

The gas controls can be found behind the control compartment access door.

Removing Control Compartment Door:

Open the door by gently liftint it upward until the hook catches on boths sides clear the locating slots. Then pull door out to remove.

On millivolt systems, the piezo igniter, HI/LO flame adjustment knob, and pilot and main gas OFF/ON control knob are located below the glass panel enclosure. The gas valve for electronic systems is also located below the glass enclosure panel. See Figure 1.

Reinstalling Control Compartment Door:

To reinstall, insert the hook catches on each side of the door into the corresponding slots in the control compartment opening, then gently push forward and slide down until it locks in place.

Manifold Gas Supply Pressure | ||

(electronic models) | ||

Fuel # | Fixed | |

|

| |

Natural Gas | 3.5" WC | |

(.87 kPa) | ||

| ||

Propane | 10.0" WC | |

(2.49 kPa) | ||

| ||

|

| |

Table 6 |

| |

#37 (.104") * | 1/16" (.0625")* | |

24M10 • | 21L01 • |

*Standard size installed at factory

• Part /Cat. Number

Table 7

Burn-in Period

During the first few fires of this appliance there

OPENING CONTROL COMPARTMENT DOOR

Control Valve

Up

Lift the Lower Control Compartment Door up and pull out to remove.

Hook Catch

Out

Lower Control Compartment Door

Test gauge connections are provided on the front of the millivolt gas control valve, identified IN for the inlet and OUT for the manifold side (see Figures 4 or 5 on Page 4). A 1/8" NPT Test gauge connection is provided at the inlet and outlet (manifold) ports on the electronic gas control valve (see Figure 3 on Page 4).

These appliances must be isolated from the gas supply piping system (by closing their individual manual

These appliances and their individual

Orifice Sizes - Sea Level to High Altitude (All Models): These appliances are tested and approved for installations at elevations of

will be some odor due to the curing of the paint and burning off of lubricants used in the manufacturing process.

Depending on your use, the

KEEP YOUR HOUSE WELL VENTILATED DURING THE CURING PROCESS. THE ODOR AND HAZE EMITTED DURING THE CURING PROCESS CAN BE QUITE NOTICEABLE AND MAY SET OFF A SMOKE DETECTOR.

If an optional blower is installed, Do not turn it on during the

A white film may develop on the glass front during the first few fires as part of the curing process. The glass should be kept clean during the first two weeks of use to prevent the film from baking on (making it very difficult to remove). See Cleaning Glass on Page 5.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Figure 1

Operation and care of your appliance

The standard controls for appliance opera- tion are located behind the panel below the appliance front glass enclosure panel (see Figure 1). Optional control switches are also

available (see Page 13 - Remote Wall Switch, Remote Control or Wall Thermostat).

Operation of millivolt and electronic gas con- trol systems are different. Before lighting and operating your appliance determine if you have a millivolt or electronic appliance. Familiarize yourself with the gas control valve that your appliance uses. Refer to Figure 1 for access to the gas control valve.