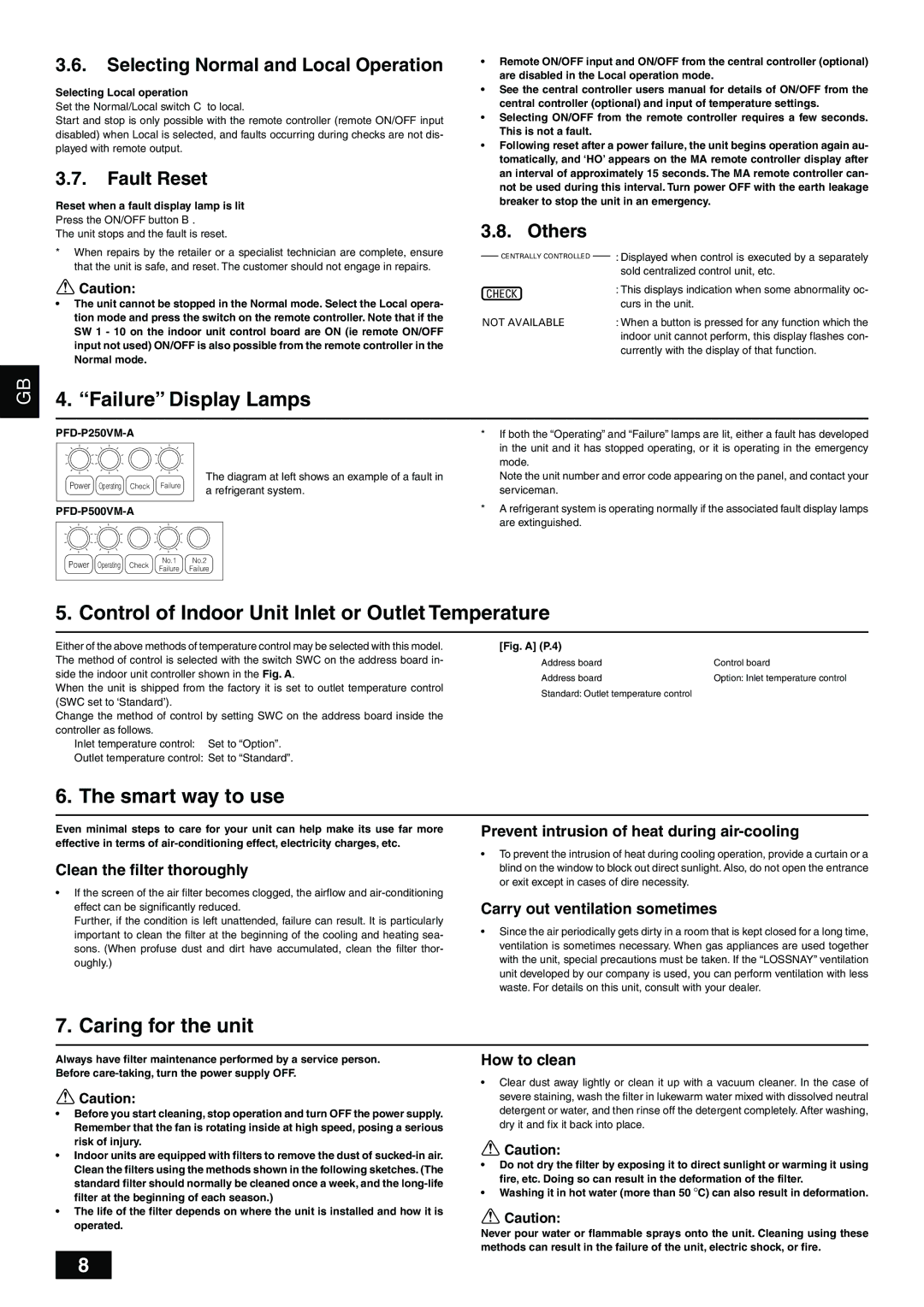

PFD-P250500VM-A specifications

The Mitsubishi Electronics PFD-P250500VM-A is a cutting-edge piece of equipment that exemplifies the company's commitment to advanced engineering and innovative technology in the field of power and automation solutions. Designed for robust performance, this model serves as a high-efficiency inverter that integrates seamlessly into various industrial applications.One of the primary features of the PFD-P250500VM-A is its high power output capacity. With a maximum output of 250 kVA, it caters effectively to high-demand environments, ensuring reliable and stable power supply for heavy machinery and equipment. This inverter is designed to optimize power consumption, thus enhancing energy efficiency and reducing operational costs for users.

The design of the PFD-P250500VM-A also emphasizes versatility, allowing it to function in multiple configurations. It supports different voltage levels and can be adapted for specific applications and requirements. This characteristic makes it an ideal choice for diverse industries, including manufacturing, utilities, and commercial sectors.

Incorporating advanced control algorithms, the PFD-P250500VM-A boasts precise torque and speed control capabilities, providing exceptional responsiveness and stability. This feature is crucial for applications that require consistent and accurate performance under varying load conditions. Furthermore, its built-in protection mechanisms safeguard against over-voltage, under-voltage, and overheating, ensuring longevity and reliability in demanding environments.

The product's user-friendly interface includes a display panel that allows for easy monitoring and adjustments. This accessibility is complemented by communication protocols ensuring connectivity with other systems, making integration into existing setups straightforward.

In terms of technology, the PFD-P250500VM-A employs state-of-the-art semiconductor technology, ensuring minimal losses during operation. This contributes not only to the efficiency of the unit but also to lower environmental impact by maximizing energy usage.

Lastly, Mitsubishi's commitment to quality assurance is evident in the PFD-P250500VM-A, which undergoes rigorous testing before release. This dedication to excellence ensures that the unit meets international standards and offers peace of mind to users regarding its reliability and performance.

In conclusion, the Mitsubishi Electronics PFD-P250500VM-A stands out as a premier solution for industrial power requirements, combining high output capacity, advanced control features, and robust safety measures, making it an indispensable asset for industries seeking efficiency and reliability.