SECTION 9: LUBRICATION

WARNING: Disconnect the spark plug wire and ground against the

engine before performing any lubrication or maintenance.

ENGINE

Refer to engine manual for all engine lubrication instructions.

WARNING: When following instruct- ions in separate engine manual for draining oil, be sure to protect frame to avoid oil dripping onto transmission parts.

CHUTE CRANK

The gear on the end of the chute crank should be greased with

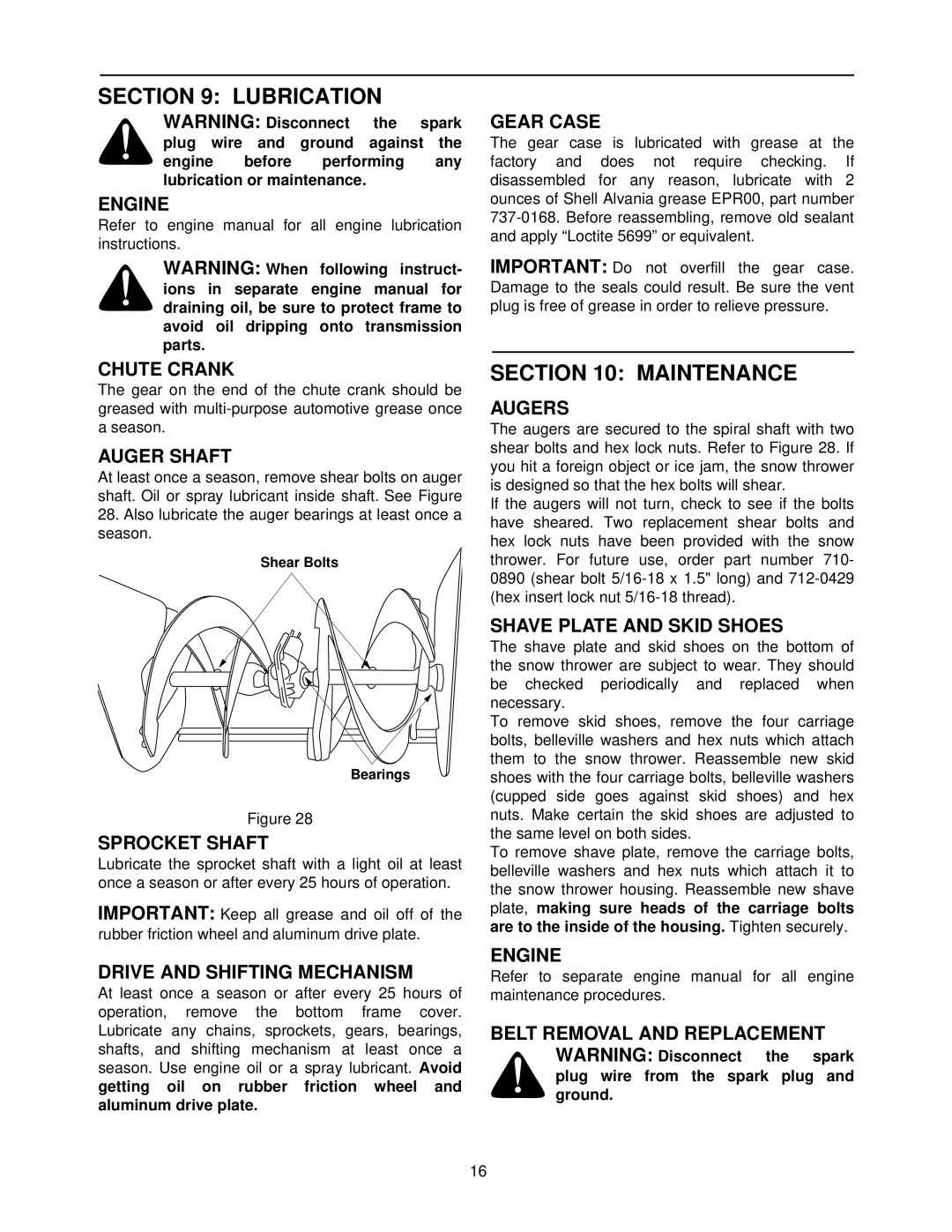

AUGER SHAFT

At least once a season, remove shear bolts on auger shaft. Oil or spray lubricant inside shaft. See Figure

28.Also lubricate the auger bearings at least once a season.

Shear Bolts

Bearings

Figure 28

SPROCKET SHAFT

Lubricate the sprocket shaft with a light oil at least once a season or after every 25 hours of operation.

IMPORTANT: Keep all grease and oil off of the rubber friction wheel and aluminum drive plate.

DRIVE AND SHIFTING MECHANISM

At least once a season or after every 25 hours of operation, remove the bottom frame cover. Lubricate any chains, sprockets, gears, bearings, shafts, and shifting mechanism at least once a season. Use engine oil or a spray lubricant. Avoid getting oil on rubber friction wheel and aluminum drive plate.

GEAR CASE

The gear case is lubricated with grease at the factory and does not require checking. If disassembled for any reason, lubricate with 2 ounces of Shell Alvania grease EPR00, part number

IMPORTANT: Do not overfill the gear case. Damage to the seals could result. Be sure the vent plug is free of grease in order to relieve pressure.

SECTION 10: MAINTENANCE

AUGERS

The augers are secured to the spiral shaft with two shear bolts and hex lock nuts. Refer to Figure 28. If you hit a foreign object or ice jam, the snow thrower is designed so that the hex bolts will shear.

If the augers will not turn, check to see if the bolts have sheared. Two replacement shear bolts and hex lock nuts have been provided with the snow thrower. For future use, order part number 710- 0890 (shear bolt

SHAVE PLATE AND SKID SHOES

The shave plate and skid shoes on the bottom of the snow thrower are subject to wear. They should be checked periodically and replaced when necessary.

To remove skid shoes, remove the four carriage bolts, belleville washers and hex nuts which attach them to the snow thrower. Reassemble new skid shoes with the four carriage bolts, belleville washers (cupped side goes against skid shoes) and hex nuts. Make certain the skid shoes are adjusted to the same level on both sides.

To remove shave plate, remove the carriage bolts, belleville washers and hex nuts which attach it to the snow thrower housing. Reassemble new shave plate, making sure heads of the carriage bolts are to the inside of the housing. Tighten securely.

ENGINE

Refer to separate engine manual for all engine maintenance procedures.

BELT REMOVAL AND REPLACEMENT WARNING: Disconnect the spark

plug wire from the spark plug and ground.

16