Model AR13D

Diesel engine exhaust and some

AR13D RIDE-ON Roller Proposition 65WARNING

Page

AR13D RIDE-ON Roller -TABLE of Contents

Order via Fax Dealers Only

Parts Ordering Procedures

Best Deal! Order via Internet Dealers Only

Structure that does not provide ample free flow air

AR13D RIDE-ON Roller Safety Message Alert Symbols

Always wear approved eye and hearing protection

AR13D RIDE-ON Roller Safety Message Alert Symbols

Always wear approved respiratory protection

Contact with hot components can cause serious burns

AR13D RIDE-ON Roller Rules for Safe Operation

Engine or pump

Always wear seat belts

AR13D RIDE-ON Roller Rules for Safe Operation

Always know the location of the nearest fire extinguisher

Never stand below roller when it is being lifted

Machine Safety Decals

AR13D RIDE-ON Roller Operation and Safety Decals

AR13D RIDE-ON Roller Operation and Safety Decals

AR13D RIDE-ON Roller Specifications Roller

Model Briggs & Stratton DM 850D

AR13D RIDE-ON Roller Specifications Engine

Side View

AR13D RIDE-ON Roller Dimensions

AR13D RIDE-ON Roller General Information

Power Plant

Tipping Rollovers

AR13D RIDE-ON Roller General Information

Roller Components

AR13D RIDE-ON Roller Roller Components

SteeringWheel Use this wheel to steer the roller

AR13D RIDE-ON Roller Roller Components

AR13D RIDE-ON Roller Roller Components

Motor oil

AR13D RIDE-ON Roller Engine Components

+12 VDC electrical system

Cold weather conditions

Engine Oil Check

AR13D RIDE-ON Roller Inspection

Before Starting

Fuel Check

AR13D RIDE-ON Roller Inspection

Hydraulic Oil Check

Lic oil to the recommended operating level

AR13D RIDE-ON Roller Inspection

Initial Start-up Instructions Starting

AR13D RIDE-ON Roller Initial START-UP

Sprinkler Controls

Parking Brake

Vibration Button

Perform roller maintenance as indicated by and Table

AR13D RIDE-ON Roller Maintenance

Maintenance

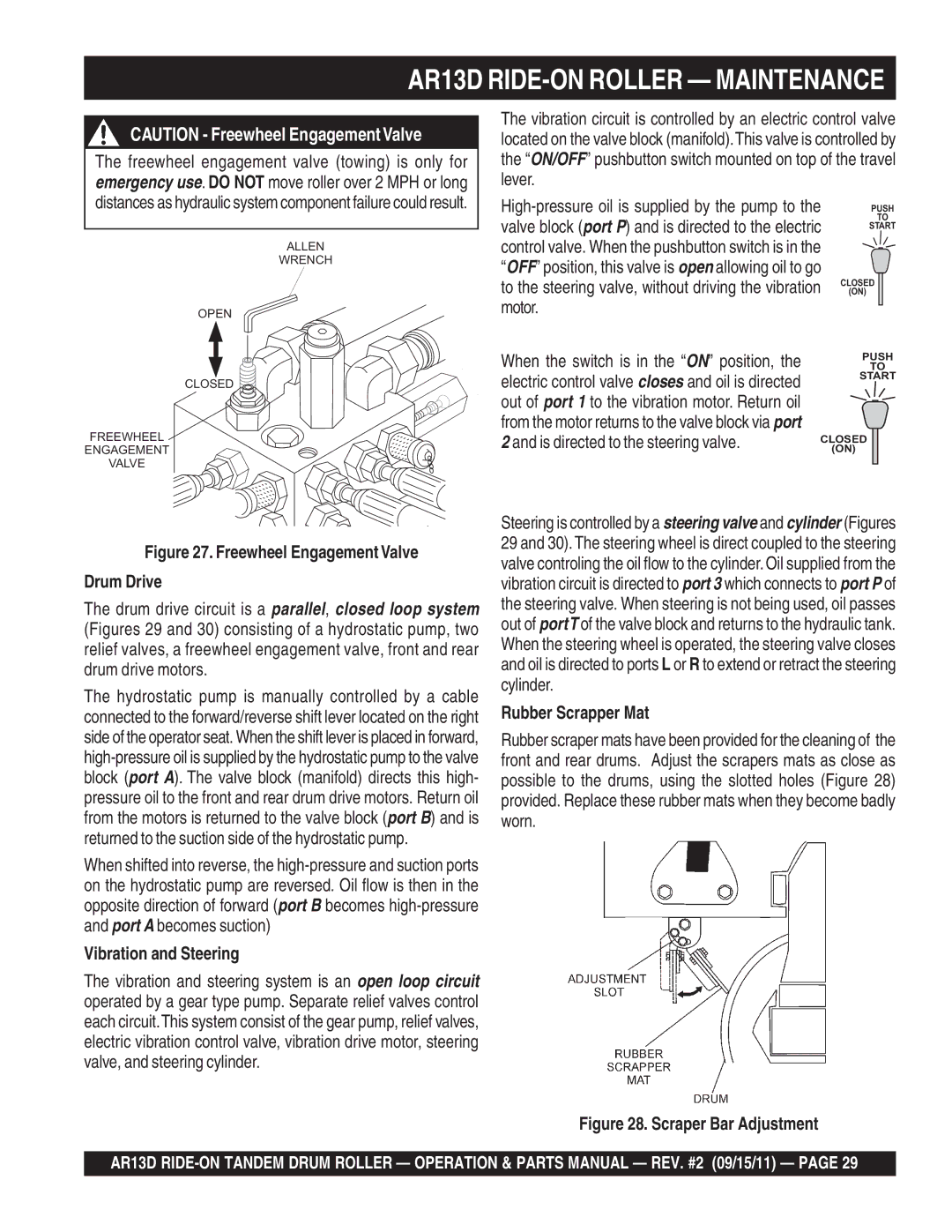

Freewheel Engagement Valve

Hydraulic Oil System

Is directed to the steering valve

AR13D RIDE-ON Roller Maintenance

Vibration and Steering

Rubber Scrapper Mat

Forward/Reverse Hydraulic Pressure Test

Adjust engine RPM 3,500 +/- 50 RPM

Vibration Circuit PressureTest

Steering Pressure Test

Forward/Reverse ReliefValves Drive Adjustment

Removing and Replacing Hydrostatic Pump

Front and Rear Drum Removal and Disassembly

Removing and Replacing Vibration/Steering Pump

Drums and Main Frame

Front-Right Drum Removal

Front-Left Drum Removal

Rear Drum Removal/Installation

Alternator/Regulator

Neutral Safety Switch

Roller Storage

AR13D RIDE-ON Roller Preparation for LONG-TERM Storage

Manifold Test Ports

AR13D RIDE-ON Roller Manifoldtest Ports

Hydraulic System Diagram

AR13D RIDE-ON Roller Hydraulic System Diagram

AR13D Roller Electricwiring Diagram

Page

Hydraulic Hose Connections

AR13D RIDE-ON Roller Hydraulic Hose Connections

AR13D RIDE-ON Roller Hydraulic Hose Connections

Manifold

Roller Troubleshooting

AR13D RIDE-ON Roller -TROUBLESHOOTING Roller

AR13D RIDE-ON Roller -TROUBLESHOOTING Engine

Engine Troubleshooting

AR13D RIDE-ON Roller -TROUBLESHOOTING Engine

Page

Xxxxx only Not Used on

Explanation of Code in Remarks Column

Description

AR13D RIDE-ON Roller Suggested Spare Parts

Name Plate and Decals

AR13D RIDE-ON Roller Name Plate and Decals

AR13D RIDE-ON Roller Name Plate and Decals

Front Drum Assy

AR13D RIDE-ON Roller Front Drum Assy

Front Roller

Housing Bearing

Bearing

RING, Retaining

Exciter Assy

AR13D RIDE-ON Roller Exciter Assy

HOUSING, Bearing Left

HOUSING, Bearing Right

SCREW, Allen 5/16

Seal

Rear Drum & Chassis Assy

AR13D RIDE-ON Roller Rear Drum & Chassis Assy

AR13D RIDE-ON Roller Rear Drum & Chassis Assy

AR13D RIDE-ON Roller Covers and Frame Articulation Lock Assy

Rear Water Tank Cover

Covers and Frame Articulation Lock Assy

Floor Plate

ARM, Floor Cover

Hood and Rear Panel Assy

AR13D RIDE-ON Roller Hood and Rear Panel Assy

HINGE, Slotted

Hood

Latch KIT Hood

Front Chassis

Steering Column and Hydraulic Articulation Assy

AR13D Steering Column and Hydraulic Articulation Assy

HARNESS, Wiring

SWITCH, Starter

Elbow Fitting

CYLINDER, Steering

Articulation ARM

AR13D RIDE-ON Roller Articulation ARM Assy

Flat Washer 3/4

ROD END

ROD, Direction Stabilizer

Hydraulic Drive Pump Assy

AR13D RIDE-ON Roller Hydraulic Drive Pump Assy

ADAPTER, Steering Pump

PUMP, Steering

Hydraulic Pump

Shift Lever

Manifold and Hydraulic OIL Filter Assy

AR13D RIDE-ON Roller Manifold and Hydraulic OIL Filter Assy

Hydraulic Tank CAP

Chassis AR13D

Straight Fitting 3/4

Filter

Fuel Tank & OIL Drain Hose Assy

AR13D RIDE-ON Roller Fueltank & OIL Drain Hose Assy

Fuel Tank

PAD, Rubber Tank

BRACKET, Fuel Tank Support

CAP, Fuel W/GAUGE

AR13D RIDE-ON Roller Watertank Assy

Water Tank Assembly Assy

Water Tank CAP

Water Tank

Clamp

Elbow PVC

Engine Mounting Assy

AR13D RIDE-ON Roller Engine Mounting Assy

452# 835034

MOUNT, Engine

Muffler Assy

AR13D RIDE-ON Roller Muffler Assy

Mount PLATE, Muffler

Bolt

Muffler Base Extension

ELBOW, Exhaust

AIR Cleaner Assy

AR13D RIDE-ON Roller AIR Cleaner Assy

ELEMENT, AIR Filter

AIR Intake Hose

Hose AIR Inlet

Radiator Assy

AR13D RIDE-ON Roller Radiator Assy

Mount Radiator Overflow

Trim EDGE1 X

NUT 1/4-20 Nylon Lock

Radiator Mounting KIT

Throttle Assy

AR13D RIDE-ON Roller -THROTTLE Assy

Travel Lever FWD/REV

Cable Throttle Assembly

CABLE, FORWARD/REVERSE

Joint Ball

Brake Control Assy

AR13D RIDE-ON Roller Brake Control Assy

Brake Link

LEVER, Brake

Bell Crank

BRACKET, Brake

Battery Assy

AR13D RIDE-ON Roller Battery Assy

AR13D RIDE-ON Roller Battery Assy

Scraper Assy

AR13D RIDE-ON Roller Scraper Assy

SCRAPER, Rubber

SCRAPER, Support

Plate Backing

NUT, Lock 1/2 NC

Freight Policy

Terms and Conditions of Sale

Page

HERE’S HOW to GET Help