DCA250SSIU, DCA250SSI specifications

The Multiquip DCA250SSI and DCA250SSIU are powerful diesel generators designed to meet the demanding energy needs of various industries. These models are specifically engineered for reliability, efficiency, and performance, making them suitable for commercial applications, construction sites, and emergency backup power.One of the standout features of both the DCA250SSI and DCA250SSIU is their impressive power output. Each model is capable of delivering 250 kVA, allowing users to run multiple equipment and tools simultaneously without worrying about power shortages. This makes them ideal for large-scale operations where consistent power is critical.

Both generators are equipped with a robust industrial-grade engine, ensuring long-lasting performance and durability. The DCA250SSI features a Kohler 4038T, whereas the DCA250SSIU includes a Yanmar engine. These engines are designed to operate efficiently under heavy loads while minimizing fuel consumption. The advanced design helps reduce emissions, making these models environmentally friendly.

The DCA250SSI and DCA250SSIU come with a sound-attenuated enclosure, which significantly reduces noise levels during operation. This design makes them suitable for use in urban settings or noise-sensitive environments, allowing businesses to comply with regulations without compromising on power supply.

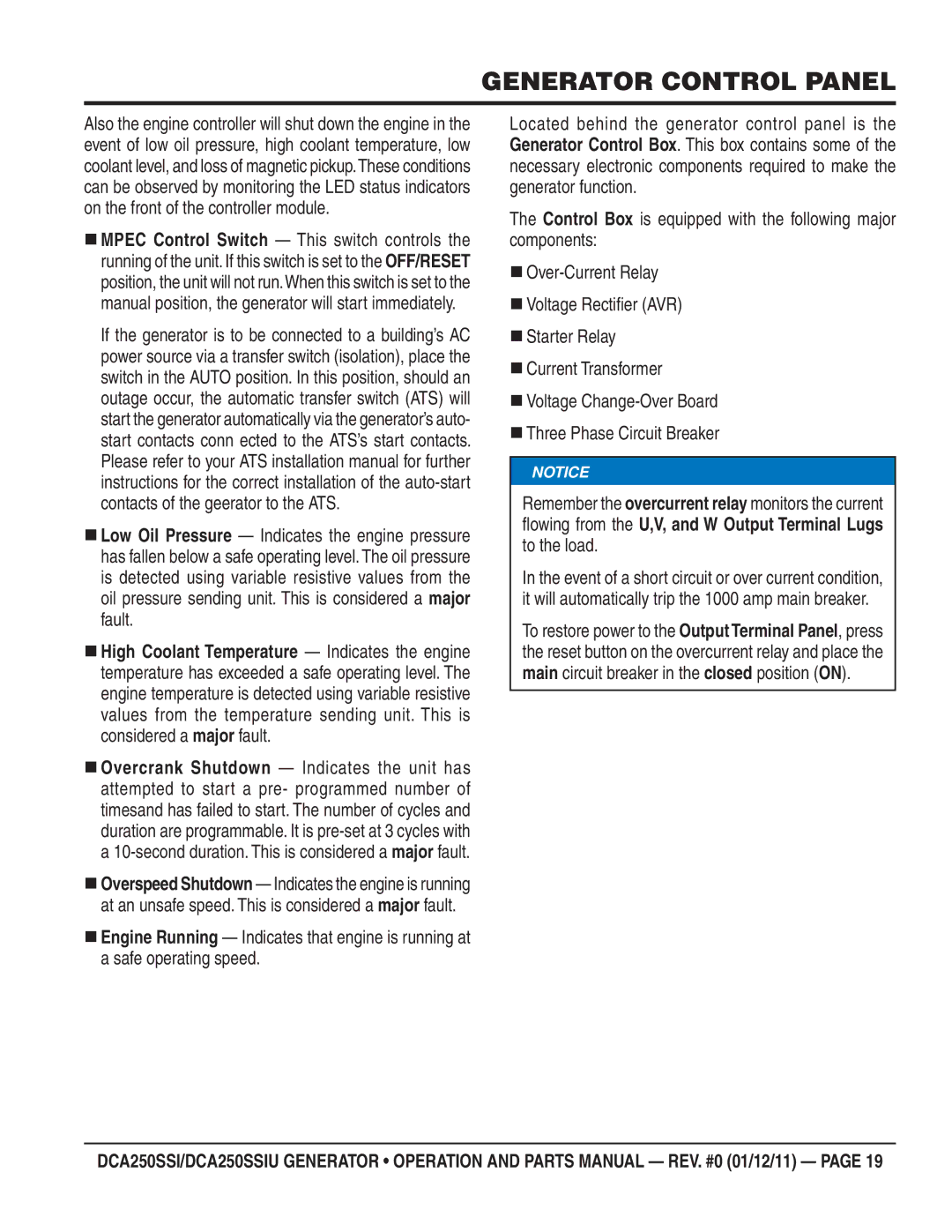

Furthermore, both models integrate advanced technologies to enhance user experience. The digital controller allows for easy monitoring and control of the generator's performance, providing crucial information such as voltage, frequency, and engine parameters in real-time. This feature helps operators stay informed of the system's status and facilitates timely maintenance when needed.

Safety is another critical consideration in the design of these generators. The DCA250SSI and DCA250SSIU include a comprehensive range of safety features, such as low oil pressure shutdown, high-temperature shutdown, and overcurrent protection, ensuring reliable operation while safeguarding against potential hazards.

Versatility is key with these models. They can be configured for both single-phase and three-phase output, catering to diverse energy requirements across different applications. Additionally, their compact design makes them easy to transport and install, further enhancing their appeal for rental companies and on-the-go operations.

In conclusion, the Multiquip DCA250SSI and DCA250SSIU stand out in the generator market with their blend of power output, fuel efficiency, noise reduction, and advanced technologies. Their robust design and safety features make them a reliable choice for a wide array of industries, offering peace of mind and consistent energy wherever it's needed.