Safety Information

TRanspORTIng saFeTY

![]() CauTIOn

CauTIOn

Before lifting, make sure that light tower parts are not damaged and screws are not loosened or lost.

ALWAYS make sure crane or lifting device has been properly secured to lifting hook of the equipment.

neveR lift the equipment while engine is running.

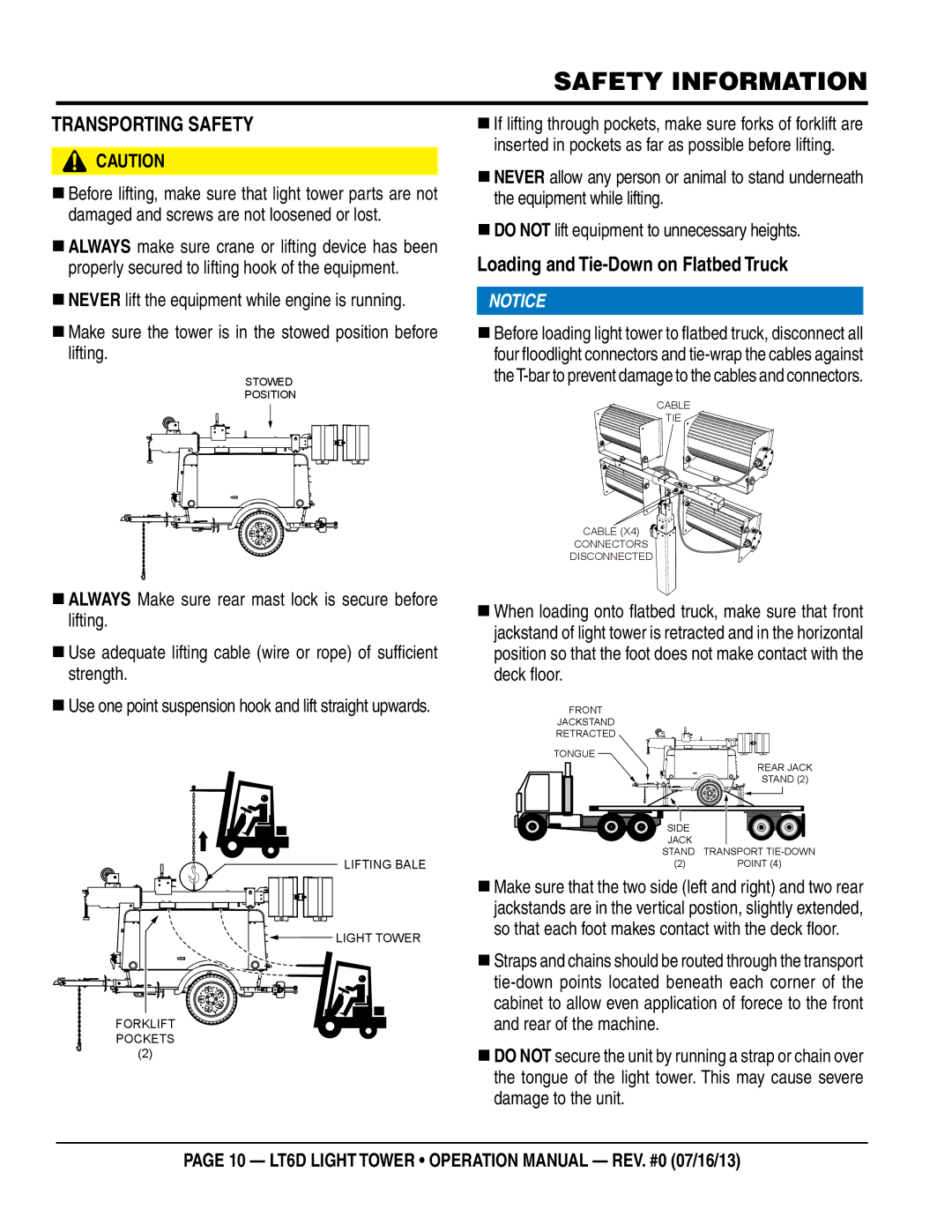

Make sure the tower is in the stowed position before lifting.

STOWED

POSITION

ALWAYS Make sure rear mast lock is secure before lifting.

Use adequate lifting cable (wire or rope) of suffi cient strength.

Use one point suspension hook and lift straight upwards.

LIFTING BALE

![]() LIGHT TOWER

LIGHT TOWER

FORKLIFT POCKETS

(2)

If lifting through pockets, make sure forks of forklift are inserted in pockets as far as possible before lifting.

neveR allow any person or animal to stand underneath the equipment while lifting.

DO nOT lift equipment to unnecessary heights.

Loading and Tie-Down on Flatbed Truck

NOTICE

Before loading light tower to fl atbed truck, disconnect all four fl oodlight connectors and

CABLE

![]()

![]()

![]()

![]()

![]()

![]()

![]() TIE

TIE ![]()

![]()

CABLE (X4)

CONNECTORS

DISCONNECTED

When loading onto fl atbed truck, make sure that front jackstand of light tower is retracted and in the horizontal position so that the foot does not make contact with the deck fl oor.

FRONT

JACKSTAND

RETRACTED

TONGUE

REAR JACK

STAND (2)

SIDE |

|

JACK |

|

STAND | TRANSPORT |

(2) | POINT (4) |

Make sure that the two side (left and right) and two rear jackstands are in the vertical postion, slightly extended, so that each foot makes contact with the deck fl oor.

Straps and chains should be routed through the transport

DO nOT secure the unit by running a strap or chain over the tongue of the light tower. This may cause severe damage to the unit.

page 10 — LT6D LIGHT TOWER • operation manual — rev. #0 (07/16/13)