maintenance — TRAILERS

TRAILER MAINTENANCE

The following trailer maintenance guidelines are intended to assist the operator in preventive maintenance.

Adjustable Channel

Your LT6D trailer comes standard with a fixed 2" ball coupler.The tow bar channel provides a fastening option to place other couplers

![]()

![]() NOTICE

NOTICE

When replacing channel mounting hardware (nuts, bolts and washers), NEVER substitute substandard hardware. Pay close attention to bolt length and grade. ALWAYS use manufacturer's recommended parts when replacing channel mounting hardware.

Table 10. Trailer Couplers

Type | Part Number |

Fixed | P/N 29546 |

Adjustable | P/N 29720 |

Fixed Pintle/Eye | P/N 29791 |

Adjustable Pintle/Eye | P/N 29721 |

5/8” FLAT

WASHER

5/8” NYLOC

NUT

ADJUSTABLE

CHANNEL

5/8” X 11” X 5”

BOLT ![]()

![]()

![]()

![]()

![]()

![]()

![]()

2” ADJUSTABLE BALL COUPLER

PINTLE/EYE

COUPLER ![]()

Figure 31. 2-Inch Adjustable Ball/Pintle Couplers

Wheel Bearings

Wheel bearings (Figure 32) must be inspected and lubricated once a year or 12,000 miles to insure safe operation of your trailer.

If trailer wheel bearings are immersed in water, they must be replaced.

If the trailer has not been used for an extended amount of time, have the bearings inspected and packed more frequently, at least every six months and prior to use.

DANGER

If trailer wheels are under water for a long period of time, wheel bearings may fail. If this is the case, service wheel bearings immediately.

The possibility exists of the wheels falling off causing equipment damage and severe bodily harm even death!

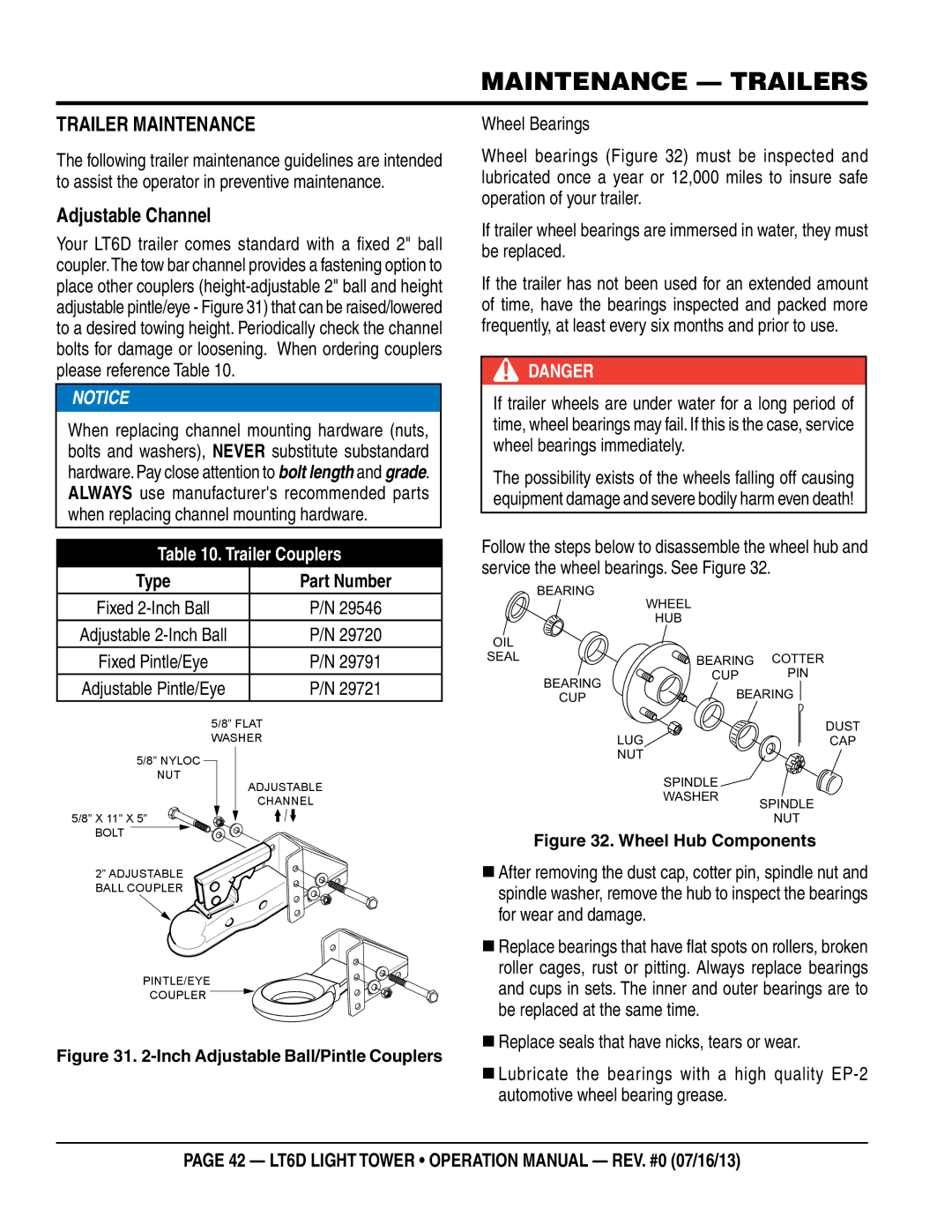

Follow the steps below to disassemble the wheel hub and service the wheel bearings. See Figure 32.

BEARING

WHEEL

HUB

OIL |

|

|

|

SEAL |

| BEARING | COTTER |

| BEARING | CUP | PIN |

| BEARING | ||

| CUP | ||

|

|

| |

|

|

| DUST |

|

| LUG | CAP |

|

| NUT |

|

SPINDLE |

|

WASHER | SPINDLE |

| |

| NUT |

Figure 32. Wheel Hub Components

After removing the dust cap, cotter pin, spindle nut and spindle washer, remove the hub to inspect the bearings for wear and damage.

Replace bearings that have flat spots on rollers, broken roller cages, rust or pitting. Always replace bearings and cups in sets. The inner and outer bearings are to be replaced at the same time.

Replace seals that have nicks, tears or wear.

Lubricate the bearings with a high quality

page 42 — LT6D LIGHT TOWER • operation manual — rev. #0 (07/16/13)