MAINTENANCE

TABLE 6. MACHINE INSPECTION

Item | Hours of Operation | ||

|

| ||

(Starting check) | Every 8 hours (every day) | ||

|

| ||

Loose or lost screws | Every 8 hours (every day) | ||

|

| ||

Damage of any part | Every 8 hours (every day) | ||

|

|

| |

Function of controlling | Every 8 hours (every day) | ||

system part | |||

|

| ||

|

|

| |

Vibrator oil check | Every 100 | hours | |

|

|

| |

Vibrator oil | Every |

| |

replacement | 300 hours |

| |

|

|

| |

Every 200 | hour | ||

|

|

| |

Daily Service

■Check for leakage of fuel or oil.

■Check engine oil.

■Check for loose screws including tightness. See Table 6 below (tightening torque ), for retightening.

TABLE 7.

TIGHTENING TORQUE (in. kg/cm) Diameter

Material | 6mm | 8mm | 10mm | 12mm | 14mm | 16mm | 18mm | 20mm |

|

|

|

|

|

|

|

|

|

4T | 70 | 150 | 300 | 500 | 750 | 1,100 | 1,400 | 2,000 |

|

|

|

|

|

|

|

|

|

100 | 250 | 500 | 800 | 1,300 | 2,000 | 2,700 | 3,800 | |

|

|

|

|

|

|

|

|

|

11T | 150 | 400 | 800 | 1,200 | 2,000 | 2,900 | 4,200 | 5,600 |

|

|

|

|

|

|

|

|

|

*100 (6mm) 300 ~ 350 (8mm) 650 ~ 700 (10mm)

*(In case

(Threads in use with this machine are all right handed)

Material and quality of material is marked on each bolt, and screw.

ENGINE OIL

1.Replace the engine oil in first 20 hours of operation and every 100 hours afterwards.

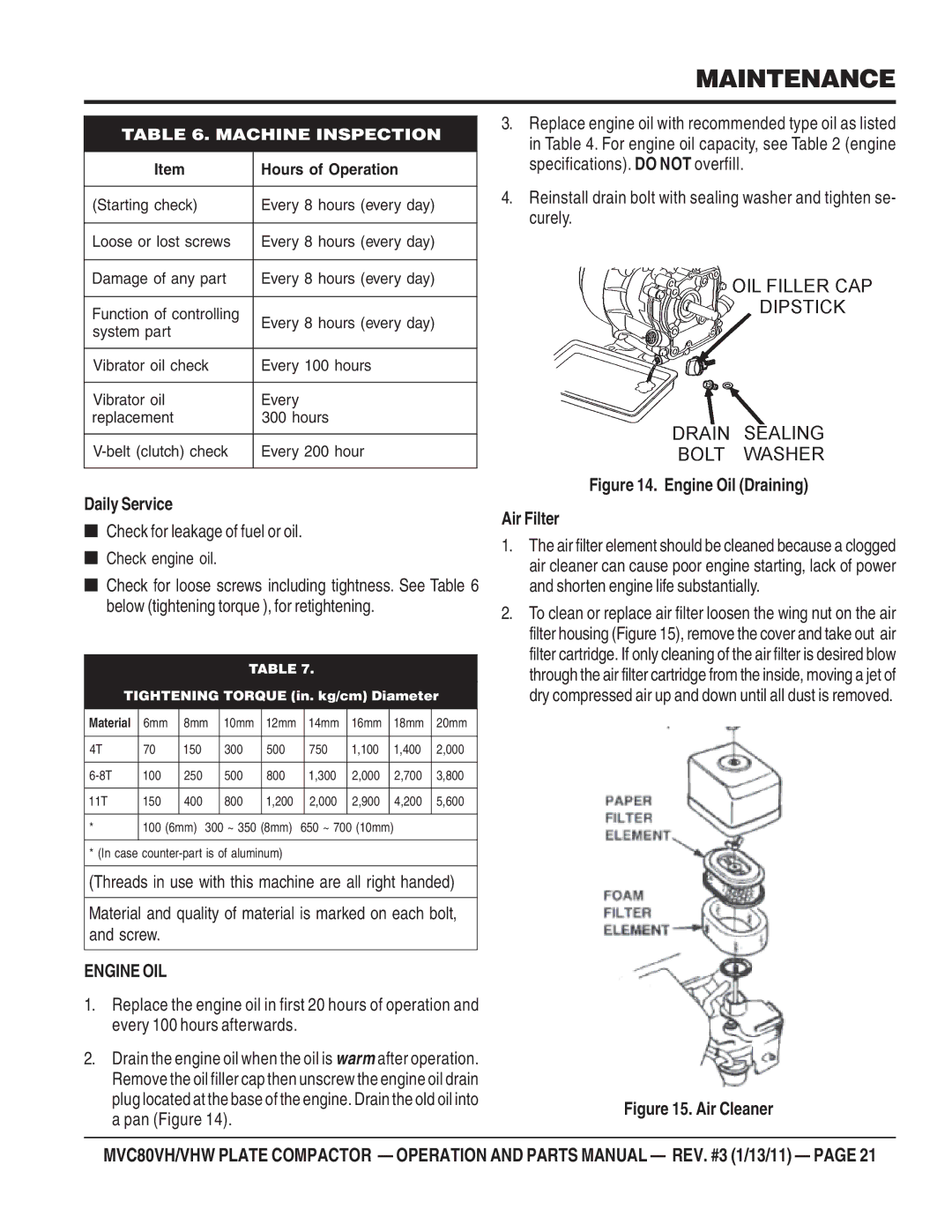

2.Drain the engine oil when the oil is warm after operation. Remove the oil filler cap then unscrew the engine oil drain plug located at the base of the engine. Drain the old oil into a pan (Figure 14).

3.Replace engine oil with recommended type oil as listed in Table 4. For engine oil capacity, see Table 2 (engine specifications). DO NOT overfill.

4.Reinstall drain bolt with sealing washer and tighten se- curely.

Figure 14. Engine Oil (Draining)

Air Filter

1.The air filter element should be cleaned because a clogged air cleaner can cause poor engine starting, lack of power and shorten engine life substantially.

2.To clean or replace air filter loosen the wing nut on the air filter housing (Figure 15), remove the cover and take out air filter cartridge. If only cleaning of the air filter is desired blow through the air filter cartridge from the inside, moving a jet of dry compressed air up and down until all dust is removed.

Figure 15. Air Cleaner

MVC80VH/VHW PLATE COMPACTOR — OPERATION AND PARTS MANUAL — REV. #3 (1/13/11) — PAGE 21