MAINTENANCE

Vibrator Oil Level Check

NOTICE

Alwayscleantheareaaroundthevibratoroillevelcheckplug before removing oil check plug. This will prevent dirt and debris from entering the system.

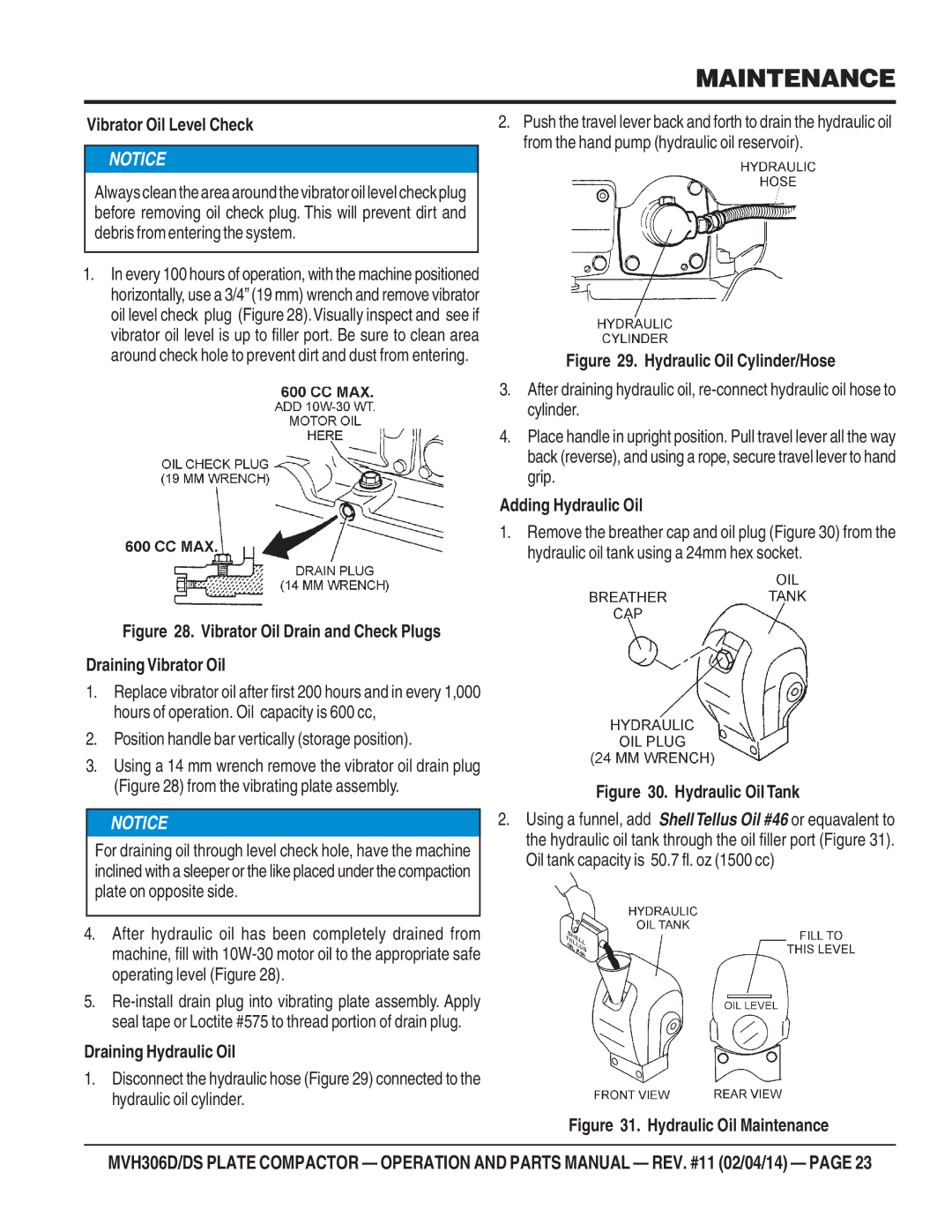

1.In every 100 hours of operation, with the machine positioned horizontally, use a 3/4” (19 mm) wrench and remove vibrator oil level check plug (Figure 28).Visually inspect and see if vibrator oil level is up to filler port. Be sure to clean area around check hole to prevent dirt and dust from entering.

Figure 28. Vibrator Oil Drain and Check Plugs

DrainingVibrator Oil

1.Replace vibrator oil after first 200 hours and in every 1,000 hours of operation. Oil capacity is 600 cc,

2.Position handle bar vertically (storage position).

3.Using a 14 mm wrench remove the vibrator oil drain plug (Figure 28) from the vibrating plate assembly.

NOTICE

For draining oil through level check hole, have the machine inclined with a sleeper or the like placed under the compaction plate on opposite side.

4.After hydraulic oil has been completely drained from machine, fill with

5.

Draining Hydraulic Oil

1.Disconnect the hydraulic hose (Figure 29) connected to the hydraulic oil cylinder.

2.Push the travel lever back and forth to drain the hydraulic oil from the hand pump (hydraulic oil reservoir).

Figure 29. Hydraulic Oil Cylinder/Hose

3.After draining hydraulic oil,

4.Place handle in upright position. Pull travel lever all the way back (reverse), and using a rope, secure travel lever to hand grip.

Adding Hydraulic Oil

1.Remove the breather cap and oil plug (Figure 30) from the hydraulic oil tank using a 24mm hex socket.

Figure 30. Hydraulic Oil Tank

2.Using a funnel, add ShellTellus Oil #46 or equavalent to the hydraulic oil tank through the oil filler port (Figure 31). Oil tank capacity is 50.7 fl. oz (1500 cc)

Figure 31. Hydraulic Oil Maintenance

MVH306D/DS PLATE COMPACTOR — OPERATION AND PARTS MANUAL — REV. #11 (02/04/14) — PAGE 23