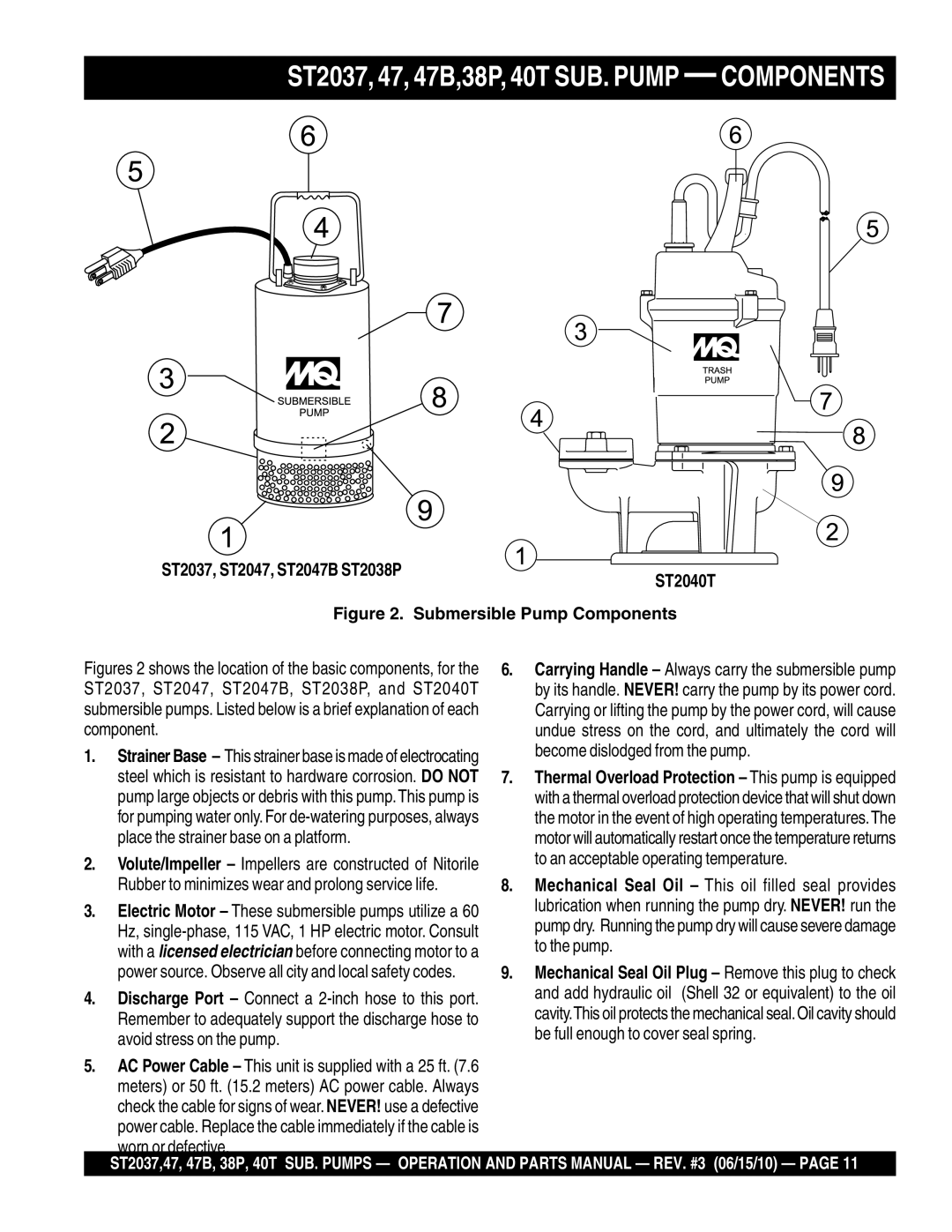

ST2037, 47, 47B,38P, 40T SUB. PUMP — COMPONENTS

ST2037, ST2047, ST2047B ST2038P

ST2040T

ST2040T

Figure 2. Submersible Pump Components

Figures 2 shows the location of the basic components, for the ST2037, ST2047, ST2047B, ST2038P, and ST2040T submersible pumps. Listed below is a brief explanation of each component.

1.Strainer Base – This strainer base is made of electrocating steel which is resistant to hardware corrosion. DO NOT pump large objects or debris with this pump.This pump is for pumping water only. For

2.Volute/Impeller – Impellers are constructed of Nitorile Rubber to minimizes wear and prolong service life.

3.Electric Motor – These submersible pumps utilize a 60 Hz,

4.Discharge Port – Connect a

5.AC Power Cable – This unit is supplied with a 25 ft. (7.6 meters) or 50 ft. (15.2 meters) AC power cable. Always check the cable for signs of wear. NEVER! use a defective power cable. Replace the cable immediately if the cable is worn or defective.

6.Carrying Handle – Always carry the submersible pump by its handle. NEVER! carry the pump by its power cord. Carrying or lifting the pump by the power cord, will cause undue stress on the cord, and ultimately the cord will become dislodged from the pump.

7.Thermal Overload Protection – This pump is equipped with a thermal overload protection device that will shut down the motor in the event of high operating temperatures.The motor will automatically restart once the temperature returns to an acceptable operating temperature.

8.Mechanical Seal Oil – This oil filled seal provides lubrication when running the pump dry. NEVER! run the pump dry. Running the pump dry will cause severe damage to the pump.

9.Mechanical Seal Oil Plug – Remove this plug to check and add hydraulic oil (Shell 32 or equivalent) to the oil cavity.This oil protects the mechanical seal.Oil cavity should be full enough to cover seal spring.

ST2037,47, 47B, 38P, 40T SUB. PUMPS — OPERATION AND PARTS MANUAL — REV. #3 (06/15/10) — PAGE 11