maintenance (Mixer)

Drum Head Seals

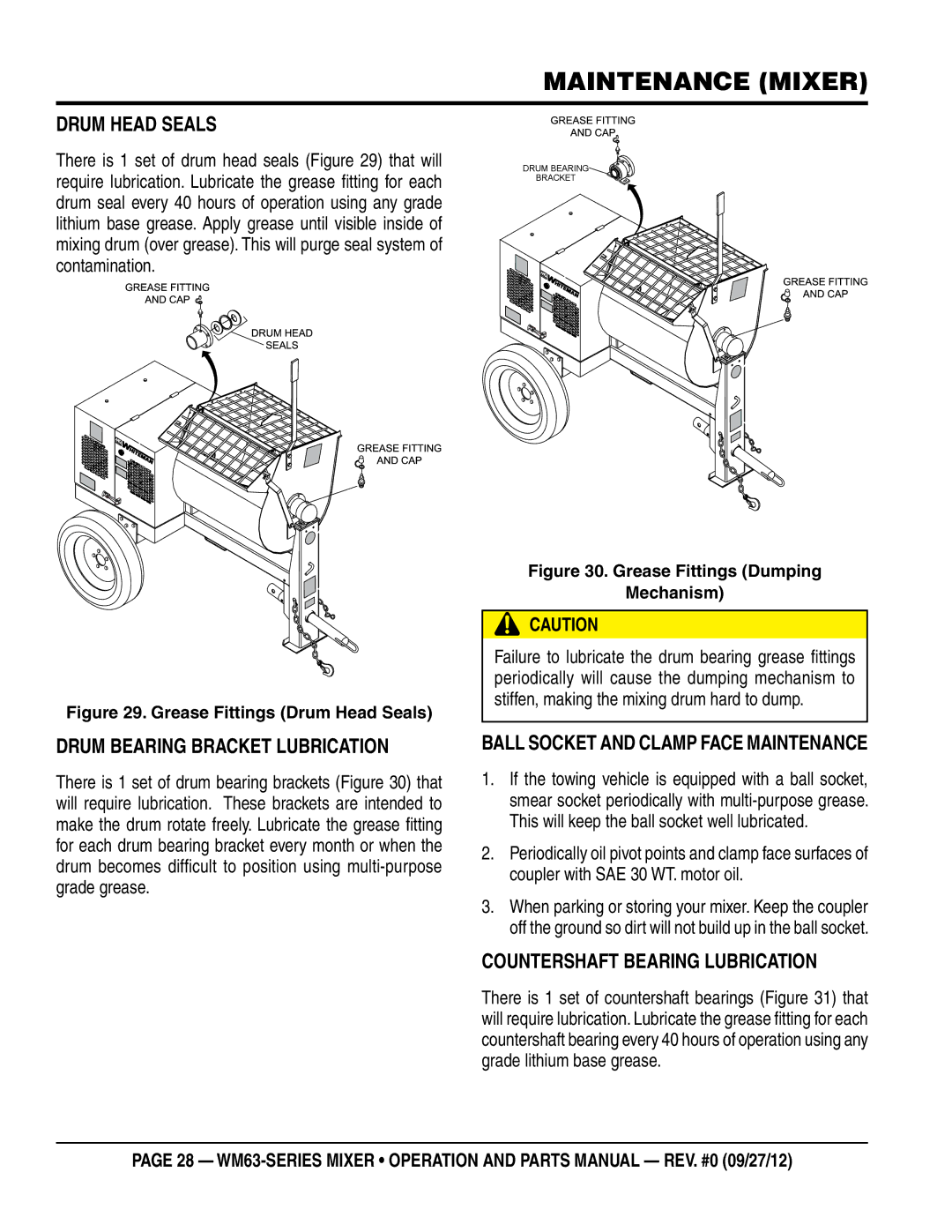

There is 1 set of drum head seals (Figure 29) that will require lubrication. Lubricate the grease fitting for each drum seal every 40 hours of operation using any grade lithium base grease. Apply grease until visible inside of mixing drum (over grease). This will purge seal system of contamination.

Figure 29. Grease Fittings (Drum Head Seals)

Drum Bearing Bracket Lubrication

There is 1 set of drum bearing brackets (Figure 30) that will require lubrication. These brackets are intended to make the drum rotate freely. Lubricate the grease fitting for each drum bearing bracket every month or when the drum becomes difficult to position using

DRUM BEARING

BRACKET

Figure 30. Grease Fittings (Dumping

Mechanism)

![]() CAUTION

CAUTION

Failure to lubricate the drum bearing grease fittings periodically will cause the dumping mechanism to stiffen, making the mixing drum hard to dump.

Ball Socket and Clamp Face Maintenance

1.If the towing vehicle is equipped with a ball socket, smear socket periodically with

2.Periodically oil pivot points and clamp face surfaces of coupler with SAE 30 WT. motor oil.

3.When parking or storing your mixer. Keep the coupler off the ground so dirt will not build up in the ball socket.

Countershaft Bearing Lubrication

There is 1 set of countershaft bearings (Figure 31) that will require lubrication. Lubricate the grease fitting for each countershaft bearing every 40 hours of operation using any grade lithium base grease.

page 28 —