maintenance (Mixer)

4.If gear teeth are not contacting properly (Figure 34), adjust pillow block to correct the problem.

HEAL

CONTACT

| FACE |

| CONTACT |

| PROPER |

TOE | CONTACT |

FLANK | |

CONTACT | CONTACT |

Figure 34. Gear Teeth Alignment

Gear Lubrication

The surface of the pinion and main gear (Figure 35) should be very lightly greased.

GREASE

FITTING

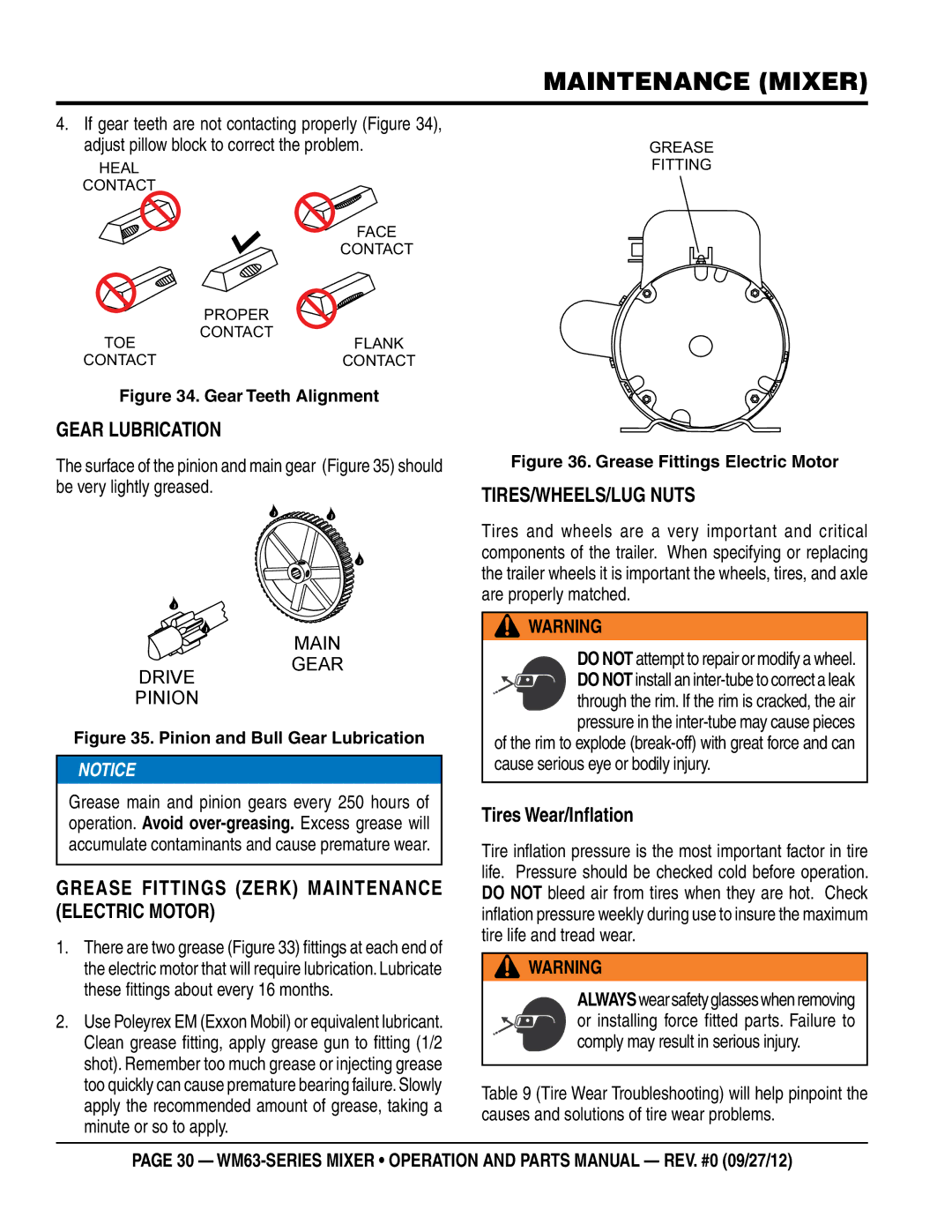

Figure 36. Grease Fittings Electric Motor

Tires/Wheels/Lug Nuts

Tires and wheels are a very important and critical components of the trailer. When specifying or replacing the trailer wheels it is important the wheels, tires, and axle are properly matched.

DRIVE

MAIN

GEAR

![]() WARNING

WARNING

DO NOT attempt to repair or modify a wheel. DO NOT install an

PINION

Figure 35. Pinion and Bull Gear Lubrication

![]()

![]() NOTICE

NOTICE

Grease main and pinion gears every 250 hours of operation. Avoid

Grease Fittings (Zerk) Maintenance (Electric Motor)

1.There are two grease (Figure 33) fittings at each end of the electric motor that will require lubrication. Lubricate these fittings about every 16 months.

2.Use Poleyrex EM (Exxon Mobil) or equivalent lubricant. Clean grease fitting, apply grease gun to fitting (1/2 shot). Remember too much grease or injecting grease too quickly can cause premature bearing failure. Slowly apply the recommended amount of grease, taking a minute or so to apply.

![]() through the rim. If the rim is cracked, the air pressure in the

through the rim. If the rim is cracked, the air pressure in the

cause serious eye or bodily injury.

Tires Wear/Inflation

Tire inflation pressure is the most important factor in tire life. Pressure should be checked cold before operation. DO NOT bleed air from tires when they are hot. Check inflation pressure weekly during use to insure the maximum tire life and tread wear.

![]() WARNING

WARNING

ALWAYS wear safety glasses when removing or installing force fitted parts. Failure to comply may result in serious injury.

Table 9 (Tire Wear Troubleshooting) will help pinpoint the causes and solutions of tire wear problems.

page 30 —