Gas-Fired Hot Water Boiler specifications

The Munchkin Gas-Fired Hot Water Boiler is a highly efficient heating system that has garnered attention in residential and commercial applications for its innovative design and advanced technology. This boiler is compact yet powerful, providing exceptional heating performance while maximizing energy efficiency.One of the standout features of the Munchkin boiler is its modulating condensing technology. This system allows the boiler to adjust its output based on demand, which optimizes energy use and reduces unnecessary fuel consumption. By modulating the flame, the Munchkin boiler can maintain a steady heating output even during variable load conditions, ensuring that users enjoy consistent hot water without waste.

The Munchkin boiler offers an impressive AFUE (Annual Fuel Utilization Efficiency) rating, typically exceeding 95%. This high efficiency translates to significant savings on energy bills and a reduced carbon footprint. By capturing and reusing flue gases that would otherwise be lost, the condensing feature enhances the overall efficiency, making it a sustainable choice for modern heating needs.

In terms of installation, the Munchkin boiler is designed for versatility. Its compact size allows for easy placement in tight spaces, whether in residential basements or utility closets. The unit is compatible with a variety of piping systems and can be integrated with multiple heating sources including radiators, baseboards, and even in-floor heating setups.

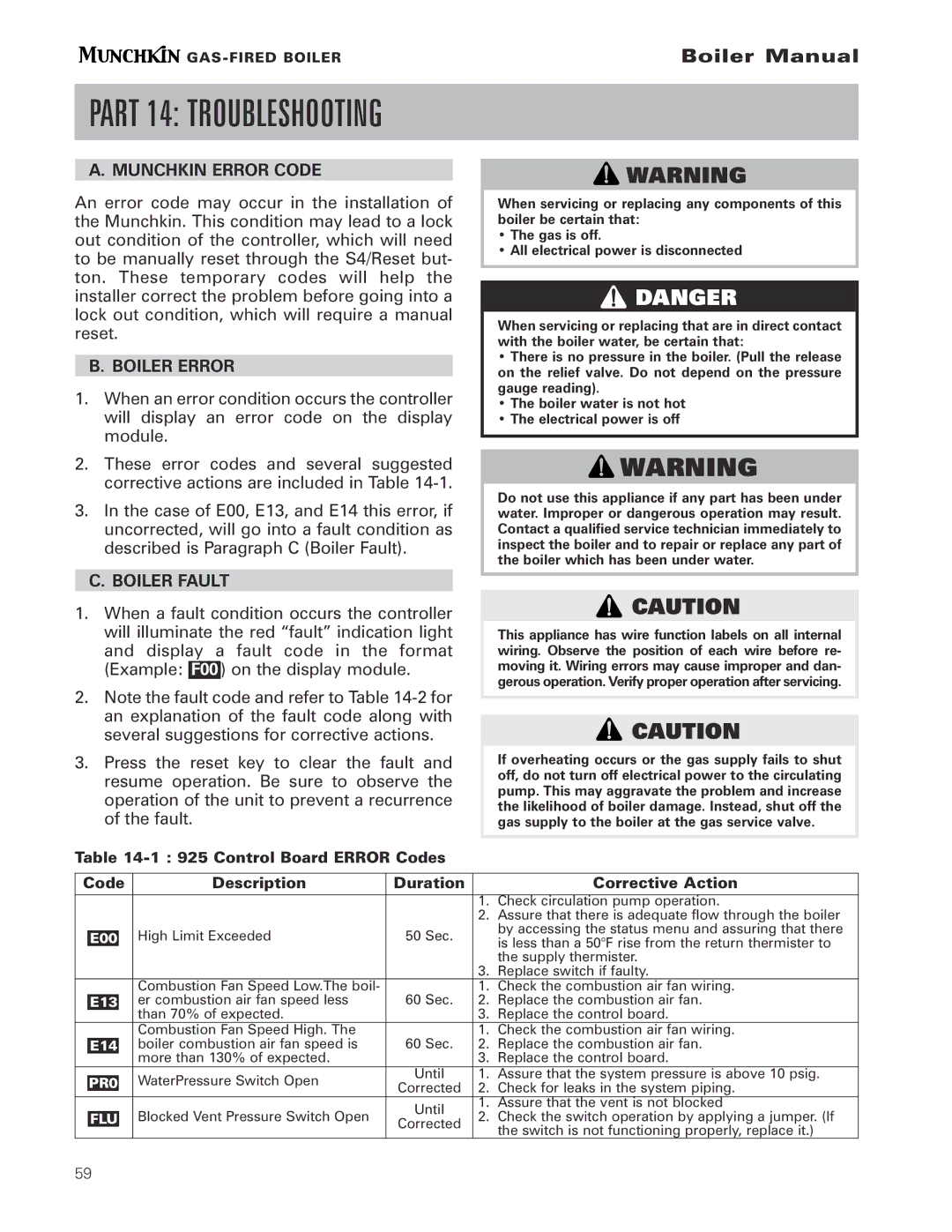

Another notable characteristic of the Munchkin boiler is its advanced control system. The boiler is equipped with a user-friendly digital display that allows for easy programming, monitoring, and adjustments. This enhanced control capability ensures that users can fine-tune their heating schedules according to their lifestyle, optimizing comfort while maintaining peak efficiency.

Reliability is a hallmark of the Munchkin brand. Built with high-quality materials, these boilers are engineered to withstand the rigors of daily operation, offering durable performance for years. Furthermore, Munchkin provides robust customer support and service options to assist homeowners and professionals alike.

In summary, the Munchkin Gas-Fired Hot Water Boiler stands out due to its modulating condensing technology, high efficiency, compact design, and advanced control system. These characteristics make it an excellent choice for those seeking a reliable, efficient, and versatile heating solution. Whether for residential or commercial use, the Munchkin boiler provides consistent, effective heating that meets the demands of today's energy-conscious consumers.