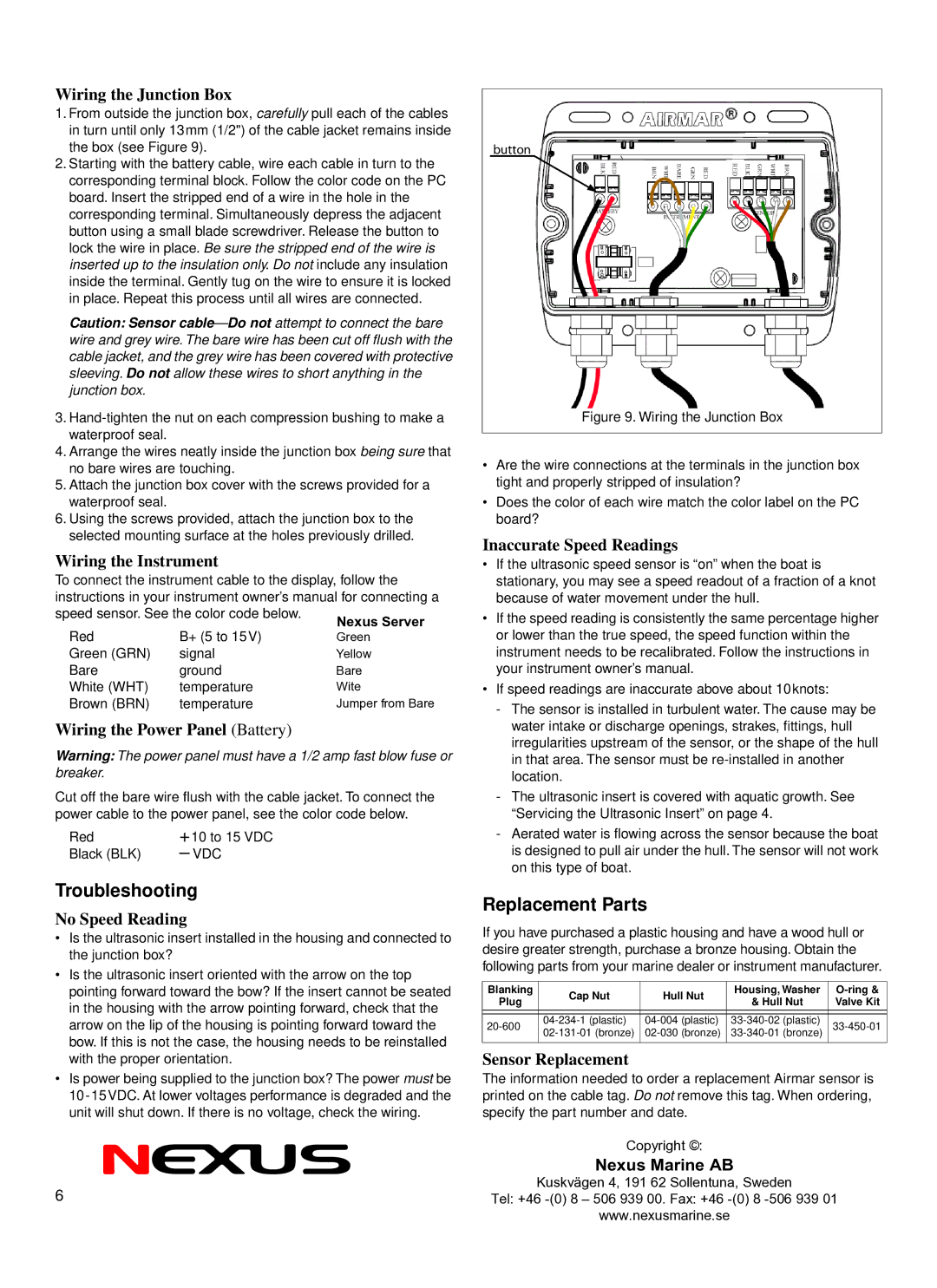

Wiring the Junction Box

1.From outside the junction box, carefully pull each of the cables in turn until only 13mm (1/2") of the cable jacket remains inside the box (see Figure 9).

2.Starting with the battery cable, wire each cable in turn to the corresponding terminal block. Follow the color code on the PC board. Insert the stripped end of a wire in the hole in the corresponding terminal. Simultaneously depress the adjacent button using a small blade screwdriver. Release the button to lock the wire in place. Be sure the stripped end of the wire is inserted up to the insulation only. Do not include any insulation inside the terminal. Gently tug on the wire to ensure it is locked in place. Repeat this process until all wires are connected.

Caution: Sensor

3.

4.Arrange the wires neatly inside the junction box being sure that no bare wires are touching.

5.Attach the junction box cover with the screws provided for a waterproof seal.

6.Using the screws provided, attach the junction box to the selected mounting surface at the holes previously drilled.

Wiring the Instrument

To connect the instrument cable to the display, follow the

instructions in your instrument owner’s manual for connecting a | |||

speed sensor. See the color code below. | Nexus Server | ||

Red | B+ (5 to 15V) | ||

Green | |||

Green (GRN) | signal | Yellow | |

Bare | ground | Bare | |

White (WHT) | temperature | Wite | |

Brown (BRN) | temperature | Jumper from Bare | |

Wiring the Power Panel (Battery)

Warning: The power panel must have a 1/2 amp fast blow fuse or breaker.

Cut off the bare wire flush with the cable jacket. To connect the power cable to the power panel, see the color code below.

Red | +10 to 15 VDC |

Black (BLK) | – VDC |

button |

|

|

|

|

|

|

|

|

button |

|

|

|

|

|

|

|

|

RED BLK | WHT BRN | BARE | GRN | RED | RED | GRN BLK | WHT | BRN |

BATTERY |

| UMENT |

|

|

|

|

| |

|

|

|

|

|

|

| ||

Figure 9. Wiring the Junction Box |

|

| ||||||

•Are the wire connections at the terminals in the junction box tight and properly stripped of insulation?

•Does the color of each wire match the color label on the PC board?

Inaccurate Speed Readings

•If the ultrasonic speed sensor is “on” when the boat is stationary, you may see a speed readout of a fraction of a knot because of water movement under the hull.

•If the speed reading is consistently the same percentage higher or lower than the true speed, the speed function within the instrument needs to be recalibrated. Follow the instructions in your instrument owner’s manual.

•If speed readings are inaccurate above about 10knots:

-The sensor is installed in turbulent water. The cause may be water intake or discharge openings, strakes, fittings, hull irregularities upstream of the sensor, or the shape of the hull in that area. The sensor must be

-The ultrasonic insert is covered with aquatic growth. See “Servicing the Ultrasonic Insert” on page 4.

-Aerated water is flowing across the sensor because the boat is designed to pull air under the hull. The sensor will not work on this type of boat.

Troubleshooting

No Speed Reading

•Is the ultrasonic insert installed in the housing and connected to the junction box?

•Is the ultrasonic insert oriented with the arrow on the top pointing forward toward the bow? If the insert cannot be seated in the housing with the arrow pointing forward, check that the arrow on the lip of the housing is pointing forward toward the bow. If this is not the case, the housing needs to be reinstalled with the proper orientation.

•Is power being supplied to the junction box? The power must be

Replacement Parts

If you have purchased a plastic housing and have a wood hull or desire greater strength, purchase a bronze housing. Obtain the following parts from your marine dealer or instrument manufacturer.

Blanking | Cap Nut | Hull Nut | Housing, Washer | ||||

Plug | & Hull Nut | Valve Kit | |||||

|

|

| |||||

|

|

|

|

|

|

| |

(plastic) | (plastic) | ||||||

(bronze) | (bronze) | ||||||

|

|

|

|

|

|

| |

Sensor Replacement

The information needed to order a replacement Airmar sensor is printed on the cable tag. Do not remove this tag. When ordering, specify the part number and date.

Copyright ©:

AIRMAR 35 Meadowbrook Drive, Milford, NewNexusHampshiMarine03055AB

TECHNOLOGY CORPORATION wwwKuskvägen.airmar.4,com191 62 Sollentuna, Sweden

6Tel: +46