Antifouling Paint

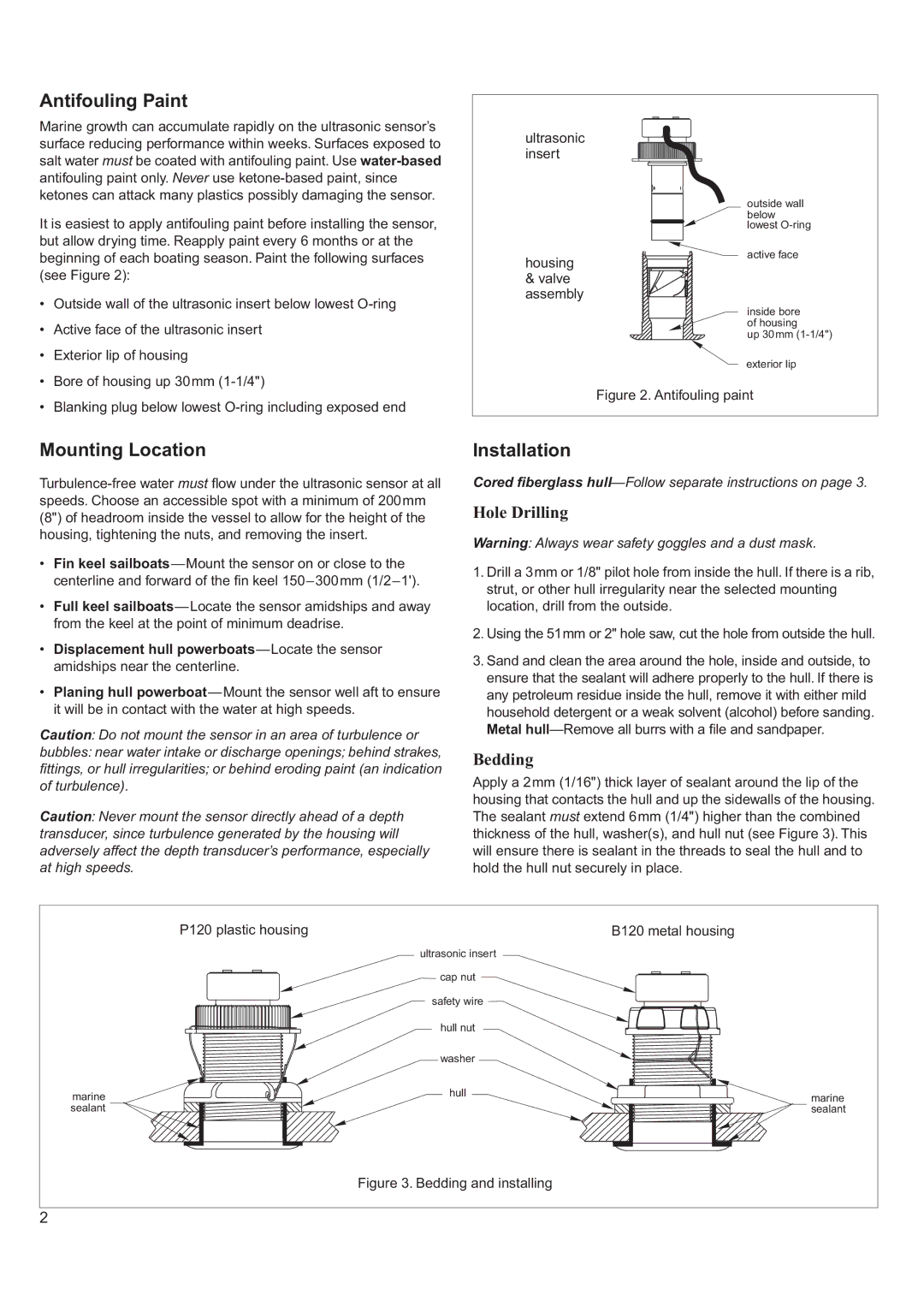

Marine growth can accumulate rapidly on the ultrasonic sensor’s surface reducing performance within weeks. Surfaces exposed to salt water must be coated with antifouling paint. Use

ultrasonic insert

It is easiest to apply antifouling paint before installing the sensor, but allow drying time. Reapply paint every 6 months or at the beginning of each boating season. Paint the following surfaces

housing

outside wall below lowest

active face

(see Figure 2):

•Outside wall of the ultrasonic insert below lowest

•Active face of the ultrasonic insert

•Exterior lip of housing

•Bore of housing up 30mm

•Blanking plug below lowest

&valve

assembly

inside bore of housing

up 30mm

exterior lip

Figure 2. Antifouling paint

Mounting Location

•Fin keel

•Full keel

•Displacement hull

•Planing hull

Caution: Do not mount the sensor in an area of turbulence or

bubbles: near water intake or discharge openings; behind strakes, fittings, or hull irregularities; or behind eroding paint (an indication of turbulence).

Caution: Never mount the sensor directly ahead of a depth transducer, since turbulence generated by the housing will adversely affect the depth transducer’s performance, especially at high speeds.

Installation

Cored fiberglass

Hole Drilling

Warning: Always wear safety goggles and a dust mask.

1.Drill a 3mm or 1/8" pilot hole from inside the hull. If there is a rib, strut, or other hull irregularity near the selected mounting location, drill from the outside.

2.Using the 51mm or 2" hole saw, cut the hole from outside the hull.

3.Sand and clean the area around the hole, inside and outside, to ensure that the sealant will adhere properly to the hull. If there is any petroleum residue inside the hull, remove it with either mild household detergent or a weak solvent (alcohol) before sanding. Metal

Bedding

Apply a 2mm (1/16") thick layer of sealant around the lip of the housing that contacts the hull and up the sidewalls of the housing. The sealant must extend 6mm (1/4") higher than the combined thickness of the hull, washer(s), and hull nut (see Figure 3). This will ensure there is sealant in the threads to seal the hull and to hold the hull nut securely in place.

P120 plastic housing |

| B120 metal housing |

| ultrasonic insert |

|

| cap nut |

|

| safety wire |

|

| hull nut |

|

| washer |

|

marine | hull | marine |

sealant |

| sealant |

| Figure 3. Bedding and installing |

|

2 |

|

|