Nilfisk P 130.2 / P 150.2 / P 160.2

EN 7 Maintenance

WARNING! Always disconnect the electrical plug from the socket prior to maintenance or cleaning.

To ensure a long and problem free working life, please take the following advice:

Wash off water hose, high pressure hose, spray lance and accessories before mounting.

7.1 Cleaning of water inlet filter

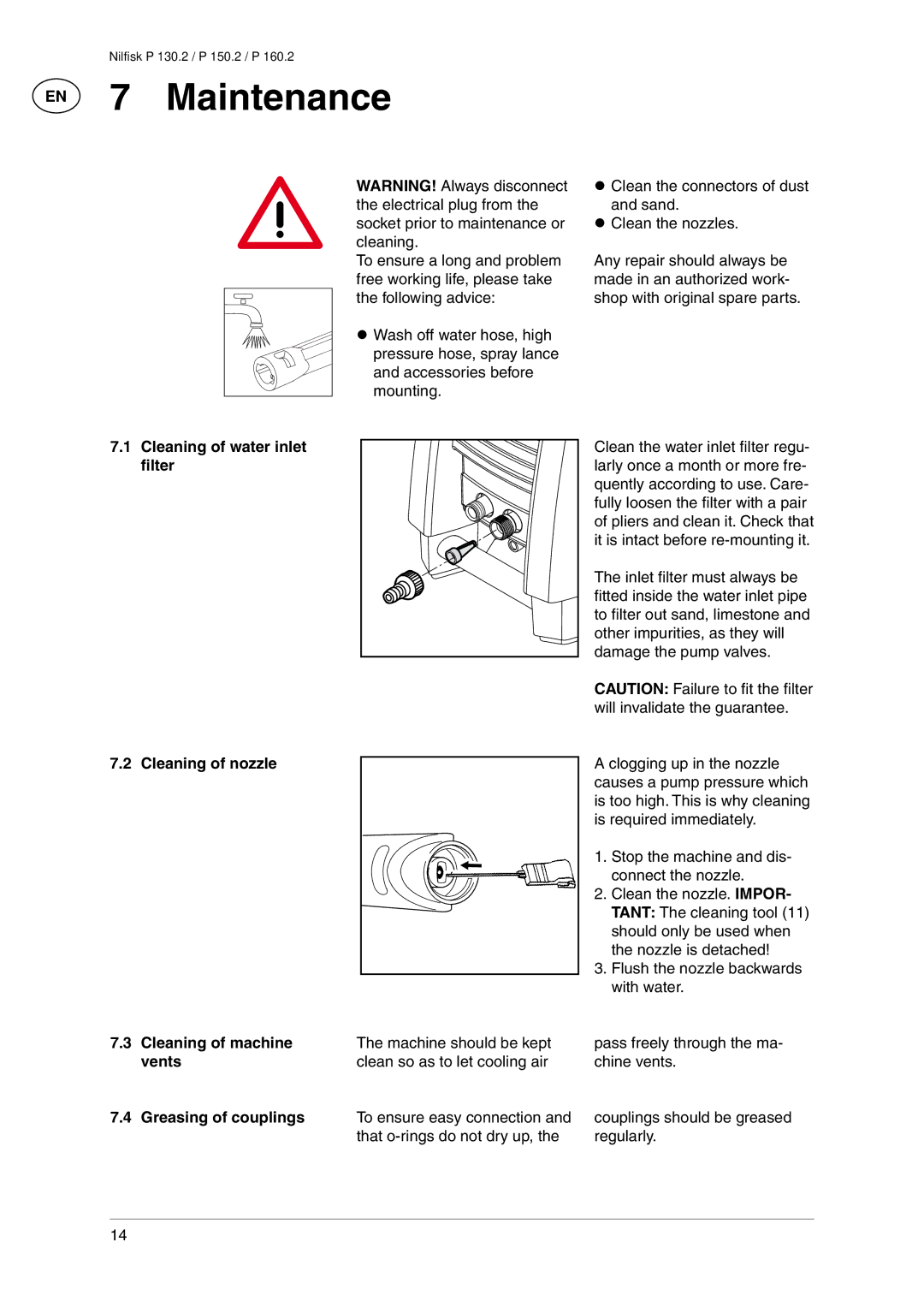

7.2 Cleaning of nozzle

7.3 | Cleaning of machine | The machine should be kept |

| vents | clean so as to let cooling air |

7.4 | Greasing of couplings | To ensure easy connection and |

|

| that |

Clean the connectors of dust and sand.

Clean the nozzles.

Any repair should always be made in an authorized work- shop with original spare parts.

Clean the water inlet filter regu- larly once a month or more fre- quently according to use. Care- fully loosen the filter with a pair of pliers and clean it. Check that it is intact before

The inlet filter must always be

fitted inside the water inlet pipe to fi lter out sand, limestone and other impurities, as they will damage the pump valves.

CAUTION: Failure to fi t the fi lter will invalidate the guarantee.

A clogging up in the nozzle causes a pump pressure which is too high. This is why cleaning is required immediately.

1.Stop the machine and dis- connect the nozzle.

2.Clean the nozzle. IMPOR- TANT: The cleaning tool (11) should only be used when the nozzle is detached!

3.Flush the nozzle backwards with water.

pass freely through the ma- chine vents.

couplings should be greased regularly.

14