Technical specifications steam blowers:

Max. steam | Air volume | Power | Nominal | Weight | Steam pipe | Condensate | Noise |

output | m3/h | supply | rating | kg |

| pipe | level (1m) |

|

|

|

|

|

|

|

|

110 | 200/240 V | 25 W | 5 | Ø 22 mm | Ø 8 mm | 46 dB (A) | |

|

|

|

|

|

|

|

|

650 | 50/60 Hz | 170 W | 15 | Ø 35 mm | Ø 8 mm | 54 dB (A) | |

|

|

|

|

|

|

|

|

32 kg/h | 800 | 220/240 V | 110 W | 8 | Ø 35 mm | Ø 8 mm | 72 dB (A) |

|

|

|

|

|

|

|

|

800 | 50/60 Hz | 110 W | 8 | 2 x Ø 35 mm | Ø 8 mm | 72 dB (A) | |

|

|

|

|

|

|

|

|

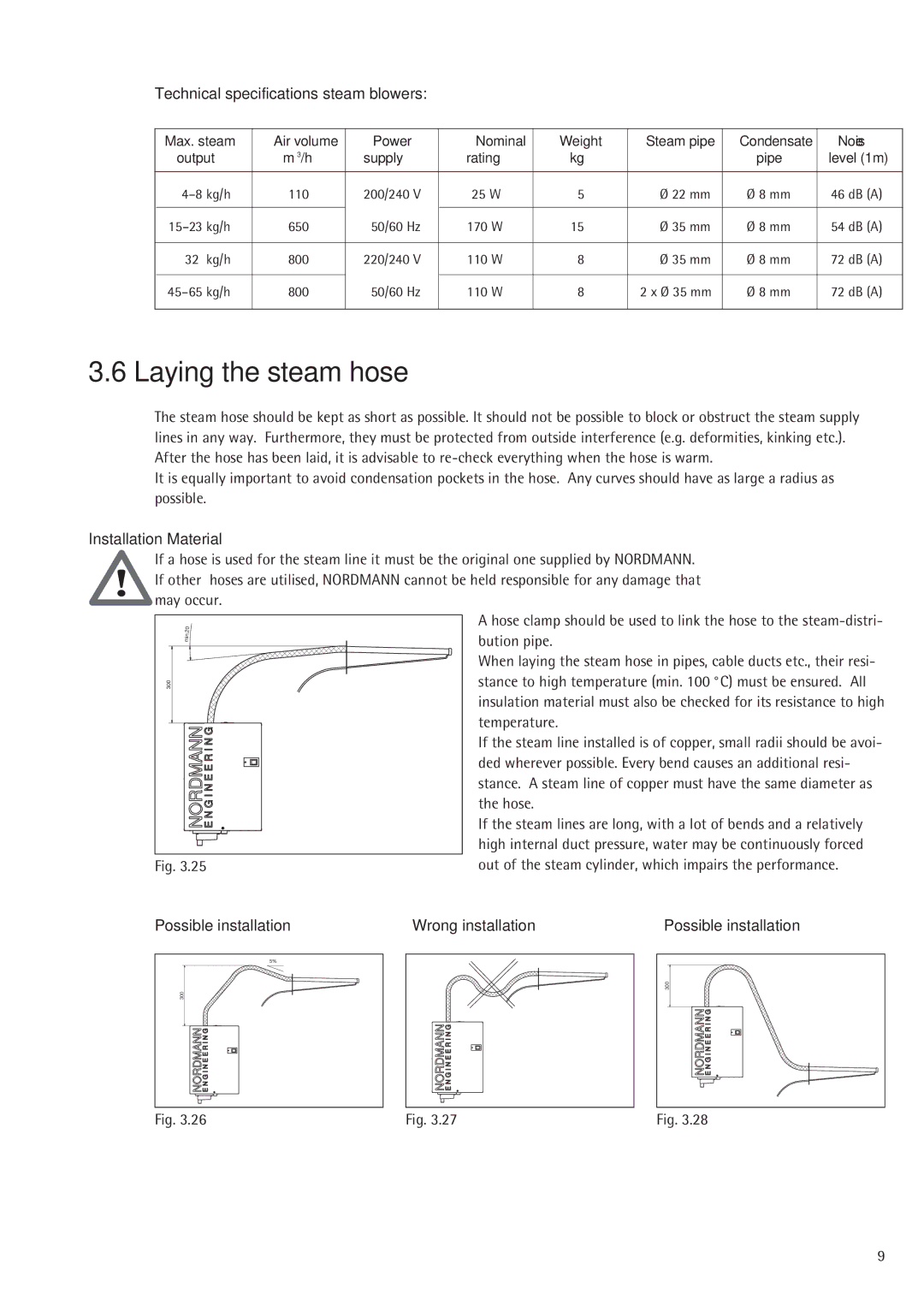

3.6 Laying the steam hose

The steam hose should be kept as short as possible. It should not be possible to block or obstruct the steam supply lines in any way. Furthermore, they must be protected from outside interference (e.g. deformities, kinking etc.). After the hose has been laid, it is advisable to

It is equally important to avoid condensation pockets in the hose. Any curves should have as large a radius as possible.

Installation Material

If a hose is used for the steam line it must be the original one supplied by NORDMANN.

!If other hoses are utilised, NORDMANN cannot be held responsible for any damage that ![]() may occur.

may occur.

° |

0 |

2 |

. |

n |

i |

m |

300 |

Fig. 3.25

A hose clamp should be used to link the hose to the

When laying the steam hose in pipes, cable ducts etc., their resi- stance to high temperature (min. 100 °C) must be ensured. All insulation material must also be checked for its resistance to high temperature.

If the steam line installed is of copper, small radii should be avoi- ded wherever possible. Every bend causes an additional resi- stance. A steam line of copper must have the same diameter as the hose.

If the steam lines are long, with a lot of bends and a relatively high internal duct pressure, water may be continuously forced out of the steam cylinder, which impairs the performance.

Possible installation | Wrong installation |

5% |

300 |

Fig. 3.26 | Fig. 3.27 |

Possible installation

300 |

Fig. 3.28

9