III. MAINTENANCE

B. Motor

The motors are specially designed for masonry sawing. It is totally enclosed and the sealed bearings require no lubrication. The motor is equipped with thermal overload protection.

1.Periodically clean the dirt and sludge

2.If the motor becomes overheated, the protector shuts the motor off. Turn the motor

switch to the "OFF" and identify the cause of overheating.

For any Electric Motor service, warranty, or technical related questions please contact your nearest Baldor service center:

Baldor Electric Company

Corporate Headquarters

5711 R.S. Boreham, Jr. St.

P.O. Box 2400

Fort Smith, AR 72901

Phone: (501)

Fax: (501)

Web Page: http://www.baldor.com/support/default.asp

C.Engine

1.Refer to the engine owner’s manual for complete maintenance.

a.

b.Paper Element: Every 100 operating hours, more often under dusty or dirty conditions clean the paper element.

c.Engine Oil: After the first month or 20 operating hours, change the oil, then every 6 months or 100 operating hours.

For any Engine service, warranty, or technical related questions please contact your nearest Honda service centers:

Honda Power Equipment Group

4900 Marconi Dr.

Alpharetta, GA

Tel: (800)

Web page:

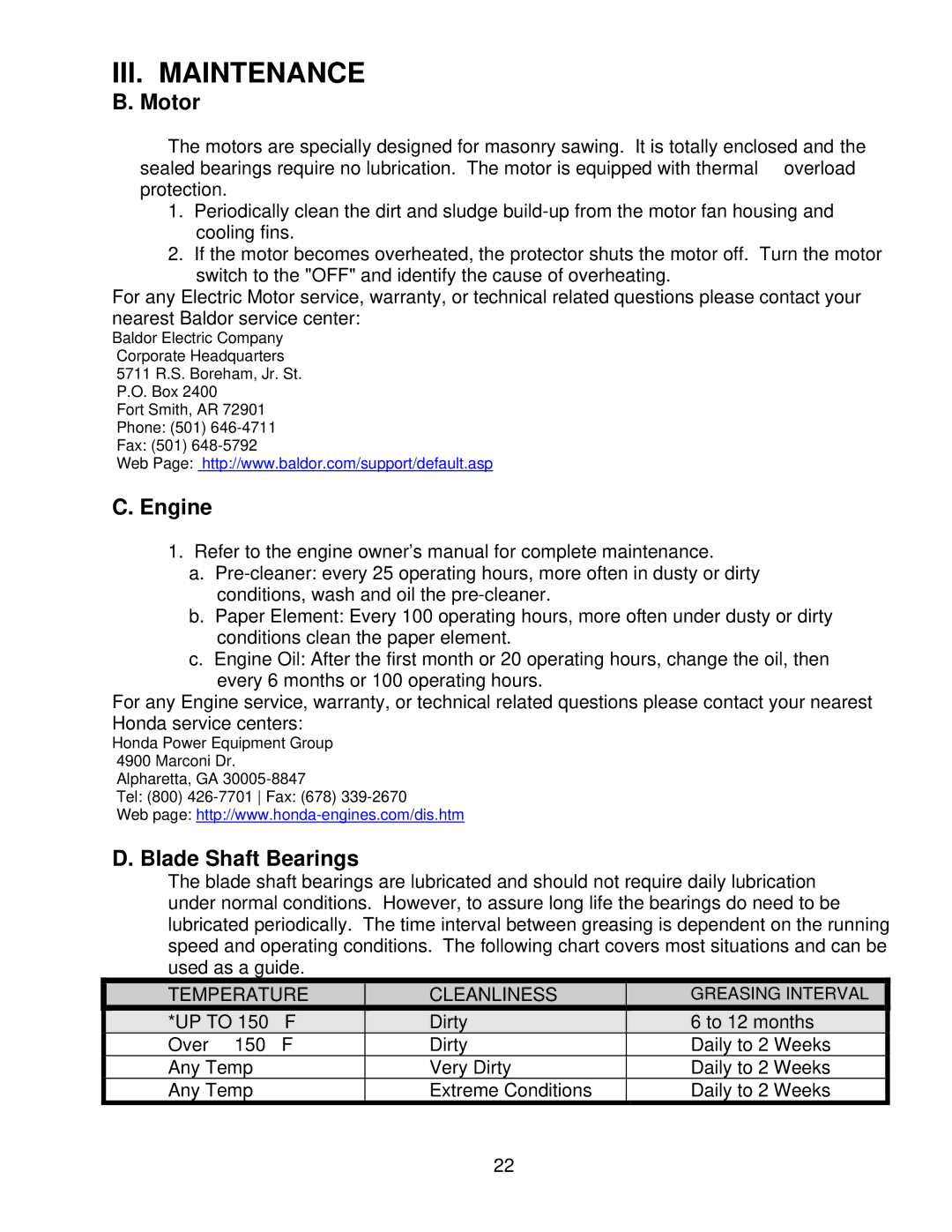

D. Blade Shaft Bearings

The blade shaft bearings are lubricated and should not require daily lubrication under normal conditions. However, to assure long life the bearings do need to be lubricated periodically. The time interval between greasing is dependent on the running speed and operating conditions. The following chart covers most situations and can be used as a guide.

| TEMPERATURE | CLEANLINESS |

| GREASING INTERVAL |

| |

|

|

|

|

|

|

|

| *UP TO 150 | F | Dirty |

| 6 to 12 months |

|

| Over 150 | F | Dirty |

| Daily to 2 Weeks |

|

| Any Temp |

| Very Dirty |

| Daily to 2 Weeks |

|

| Any Temp |

| Extreme Conditions |

| Daily to 2 Weeks |

|

22