Note: Never operate saw without bearing cover in place.

For normal conditions the grease should conform to the NLGI grade two consistency and be free of any chemical impurities such as free acid or free alkali, dust, rust, metal particles or abrasives.

For best results, the bearings should be lubricated while in operation.

Note:

Due caution for personal safety must be observed when servicing rotating equipment.

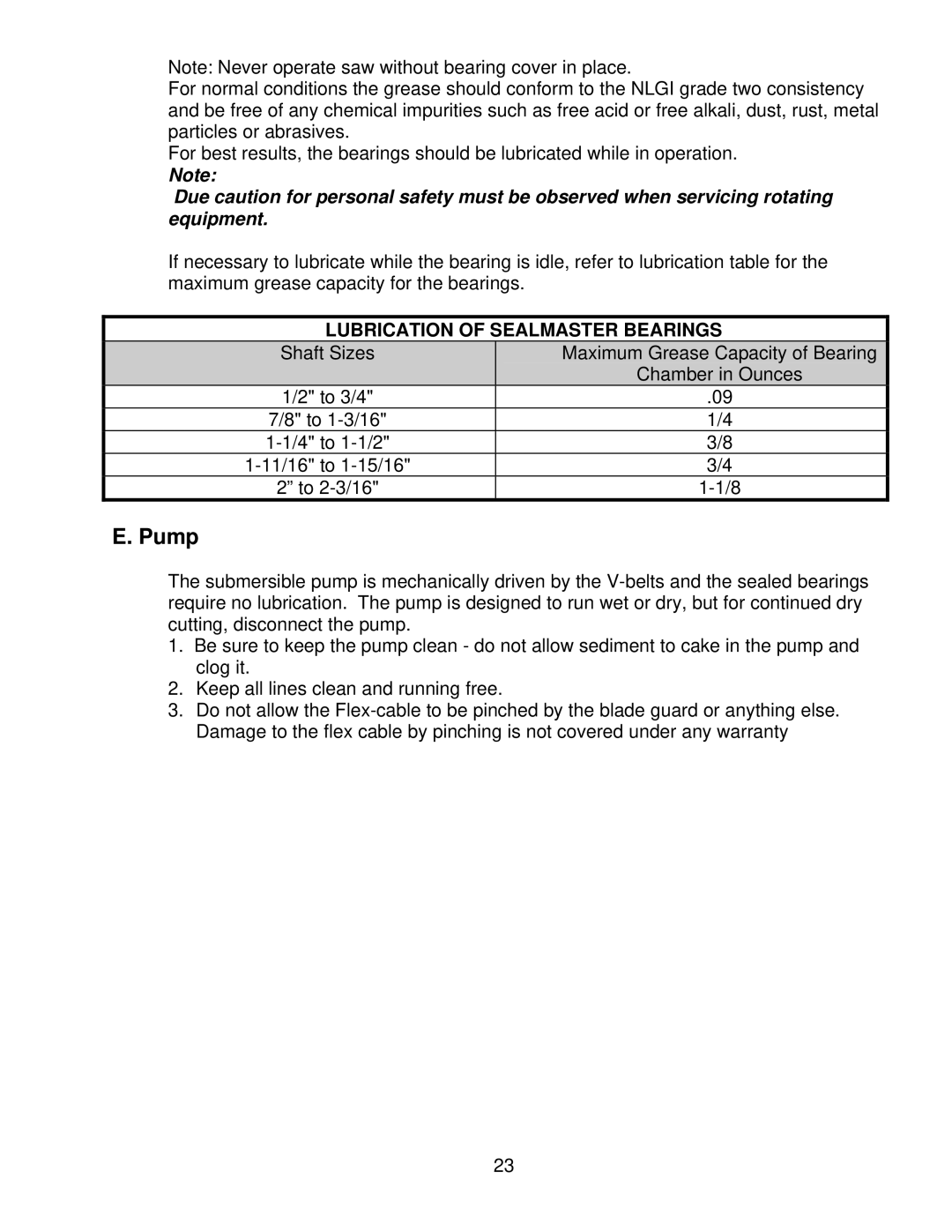

If necessary to lubricate while the bearing is idle, refer to lubrication table for the maximum grease capacity for the bearings.

LUBRICATION OF SEALMASTER BEARINGS

| Shaft Sizes | Maximum Grease Capacity of Bearing |

| |

|

|

| Chamber in Ounces |

|

| 1/2" to 3/4" | .09 |

| |

| 7/8" to | 1/4 |

| |

| 3/8 |

| ||

| 3/4 |

| ||

| 2” to |

| ||

E. Pump

The submersible pump is mechanically driven by the

1.Be sure to keep the pump clean - do not allow sediment to cake in the pump and clog it.

2.Keep all lines clean and running free.

3.Do not allow the

23