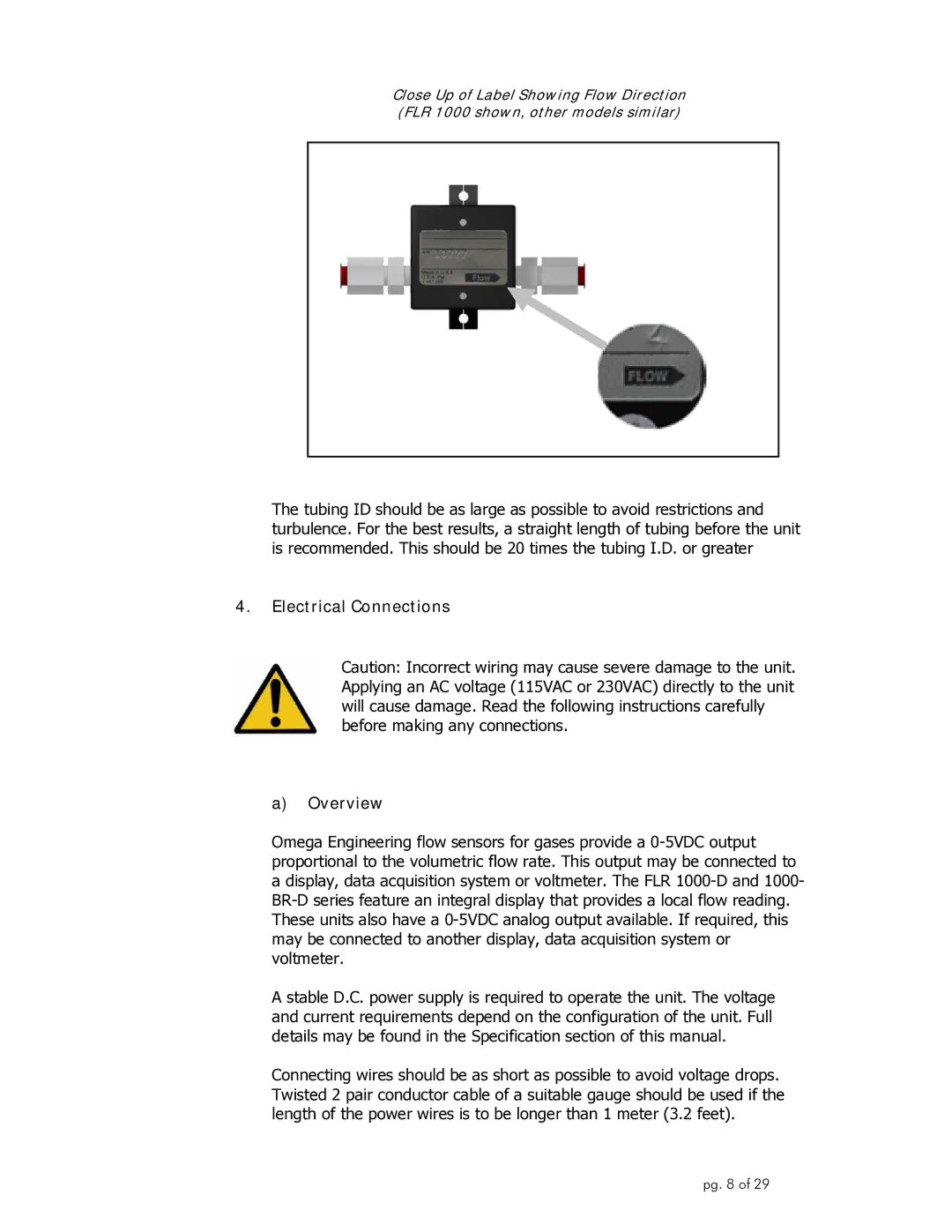

Close Up of Label Showing Flow Direction (FLR 1000 shown, other models similar)

The tubing ID should be as large as possible to avoid restrictions and turbulence. For the best results, a straight length of tubing before the unit is recommended. This should be 20 times the tubing I.D. or greater

4.Electrical Connections

Caution: Incorrect wiring may cause severe damage to the unit. Applying an AC voltage (115VAC or 230VAC) directly to the unit will cause damage. Read the following instructions carefully before making any connections.

a)Overview

Omega Engineering flow sensors for gases provide a

A stable D.C. power supply is required to operate the unit. The voltage and current requirements depend on the configuration of the unit. Full details may be found in the Specification section of this manual.

Connecting wires should be as short as possible to avoid voltage drops. Twisted 2 pair conductor cable of a suitable gauge should be used if the length of the power wires is to be longer than 1 meter (3.2 feet).

pg. 8 of 29