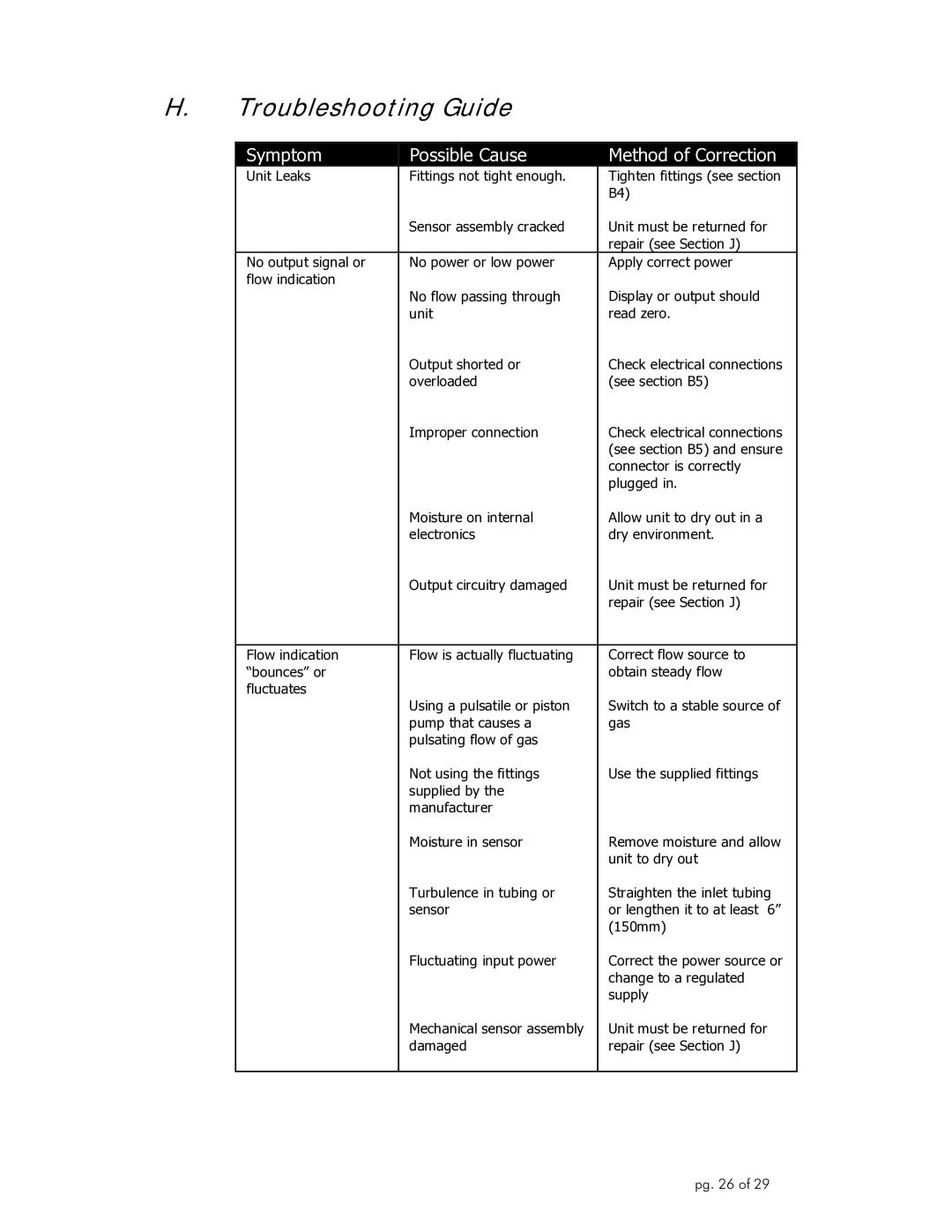

H.Troubleshooting Guide

Symptom | Possible Cause | Method of Correction |

Unit Leaks | Fittings not tight enough. | Tighten fittings (see section |

|

| B4) |

| Sensor assembly cracked | Unit must be returned for |

|

| repair (see Section J) |

No output signal or | No power or low power | Apply correct power |

flow indication | No flow passing through | Display or output should |

| ||

| unit | read zero. |

| Output shorted or | Check electrical connections |

| overloaded | (see section B5) |

| Improper connection | Check electrical connections |

|

| (see section B5) and ensure |

|

| connector is correctly |

|

| plugged in. |

| Moisture on internal | Allow unit to dry out in a |

| electronics | dry environment. |

| Output circuitry damaged | Unit must be returned for |

|

| repair (see Section J) |

|

|

|

Flow indication | Flow is actually fluctuating | Correct flow source to |

“bounces” or |

| obtain steady flow |

fluctuates | Using a pulsatile or piston | Switch to a stable source of |

| ||

| pump that causes a | gas |

| pulsating flow of gas |

|

| Not using the fittings | Use the supplied fittings |

| supplied by the |

|

| manufacturer |

|

| Moisture in sensor | Remove moisture and allow |

|

| unit to dry out |

| Turbulence in tubing or | Straighten the inlet tubing |

| sensor | or lengthen it to at least 6” |

|

| (150mm) |

| Fluctuating input power | Correct the power source or |

|

| change to a regulated |

|

| supply |

| Mechanical sensor assembly | Unit must be returned for |

| damaged | repair (see Section J) |

|

|

|

pg. 26 of 29