XL2000RH, XL2000RS specifications

The Oreck XL2000RH and XL2000RS are renowned vacuum cleaners known for their lightweight design and powerful cleaning capabilities. Designed with the user in mind, these models offer a range of features and technologies that make housekeeping a breeze.One of the standout characteristics of both models is their impressive weight. Weighing only around eight pounds, the Oreck XL series is easy to maneuver, making it ideal for all types of households. This lightweight design does not compromise performance; instead, it enhances the ease of use, allowing users to glide across carpets and hard floors with minimal effort.

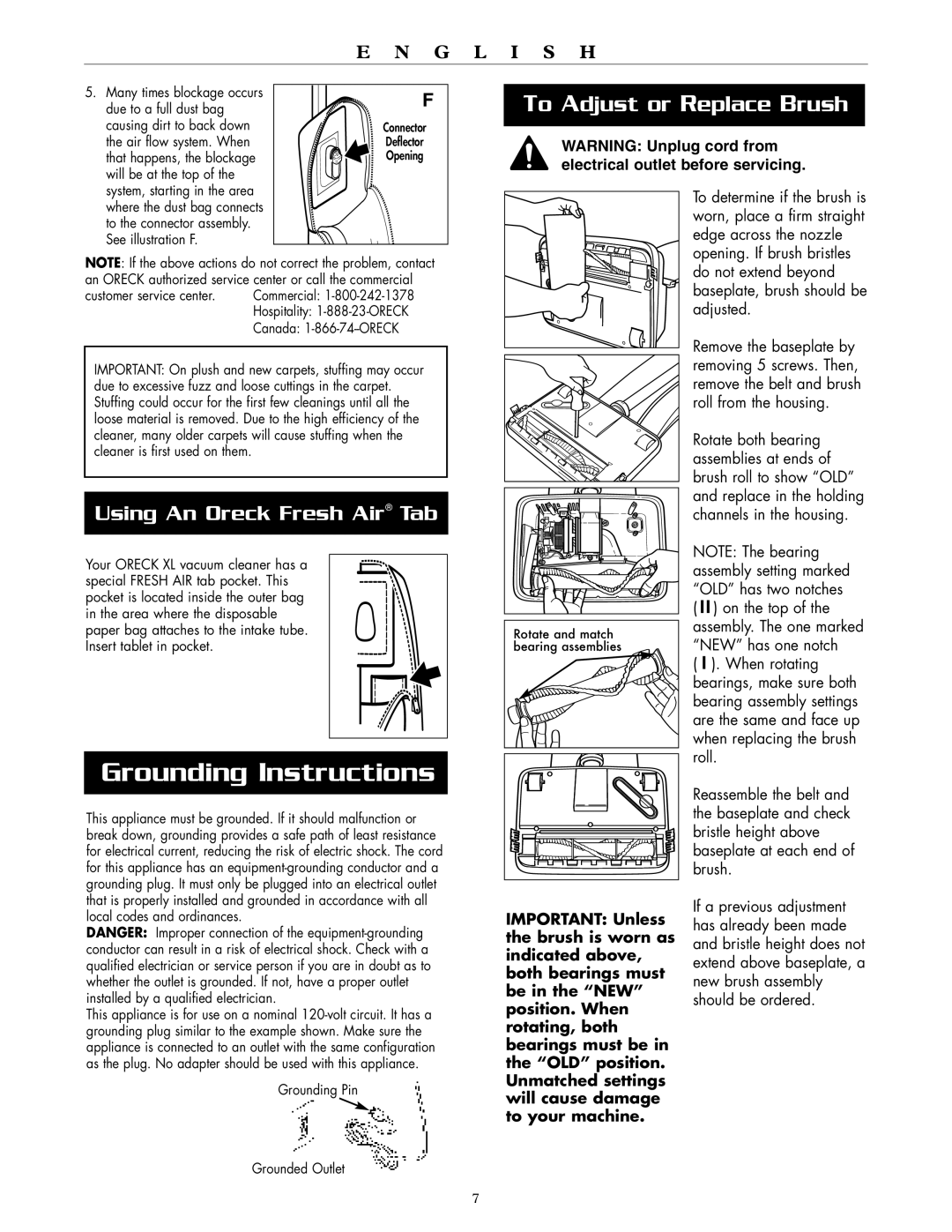

Both models feature the proprietary Oreck Dual Speed Roller Brush, which can seamlessly transition between carpet and bare floor cleaning. With a design that allows for efficient dirt pickup, this brush helps to agitate dirt and debris, ensuring thorough cleaning. The brushes are engineered to be gentle on surfaces, protecting your delicate flooring while still providing a deep clean.

Equipped with top-notch filtration technology, the XL2000RH and XL2000RS utilize a high-efficiency filter that captures dust, allergens, and other particulates. This feature is particularly beneficial for those with allergies, as the advanced filtration system helps maintain cleaner air quality within the home.

The vertical design of both models allows for exceptional reach under furniture and other hard-to-reach areas. Users appreciate the extended reach of the 40-foot power cord, which minimizes the need for frequent outlet changes, thus enhancing cleaning efficiency. Additionally, the models come with a convenient bag system that simplifies dirt disposal and minimizes mess.

Another fantastic aspect of the Oreck XL2000RH and XL2000RS is their simplicity in maintenance. The bags are easy to replace, and the motors are built for longevity, reducing the need for frequent service. These vacuums also have a manual height adjustment feature, allowing users to customize their cleaning experience based on their specific flooring types.

In summary, the Oreck XL2000RH and XL2000RS vacuum cleaners stand out for their lightweight design, powerful suction capabilities, advanced filtration system, and user-friendly features. These models are perfect for household cleaning needs, providing a blend of efficiency and ease that modern consumers seek in their cleaning appliances. Whether you have carpets, hardwood, or tile floors, these vacuums promise to deliver impressive performance and reliability.