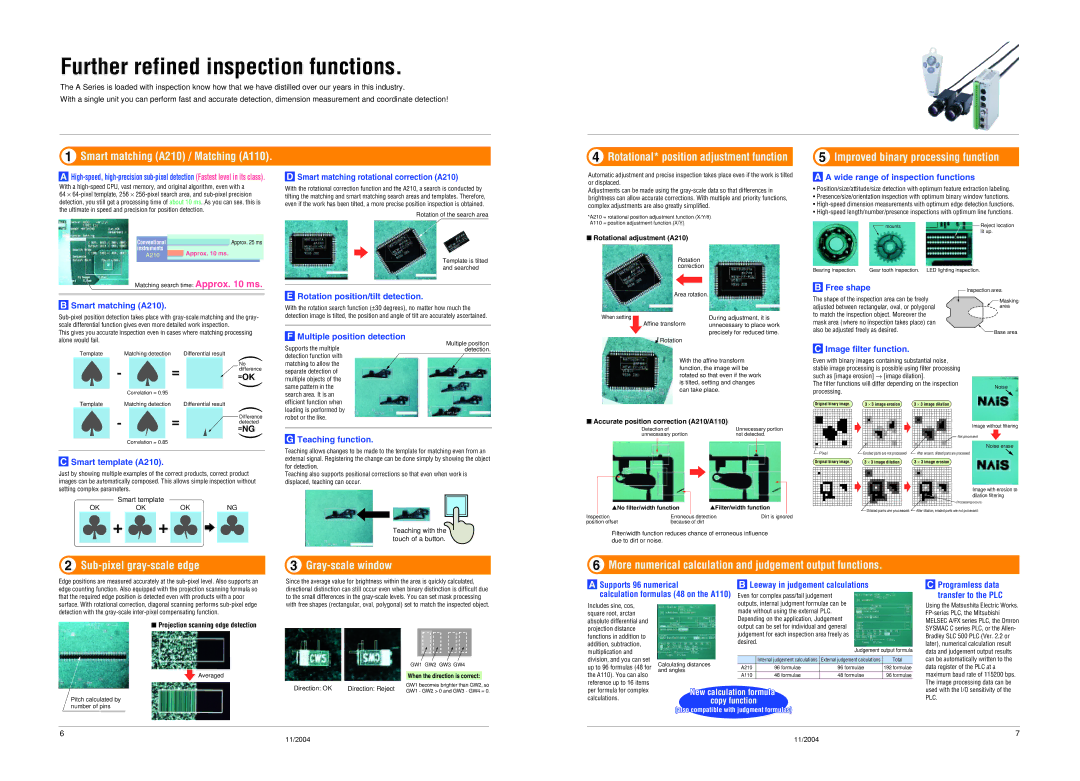

Further refined inspection functions.

The A Series is loaded with inspection know how that we have distilled over our years in this industry.

With a single unit you can perform fast and accurate detection, dimension measurement and coordinate detection!

1Smart matching (A210) / Matching (A110).

AHigh-speed, high-precision sub-pixel detection (Fastest level in its class).

With a high-speed CPU, vast memory, and original algorithm, even with a

64 ⋅ 64-pixel template, 256 ⋅ 256-pixel search area, and sub-pixel precision detection, you still get a processing time of about 10 ms. As you can see, this is the ultimate in speed and precision for position detection.

Conventional  Approx. 25 ms

Approx. 25 ms

instruments | | Approx. 10 ms. |

A210 | |

| |

Matching search time: Approx. 10 ms.

DSmart matching rotational correction (A210)

With the rotational correction function and the A210, a search is conducted by tilting the matching and smart matching search areas and templates. Therefore, even if the work has been tilted, a more precise position inspection is obtained.

Rotation of the search area

Template is tilted and searched

4Rotational* position adjustment function

Automatic adjustment and precise inspection takes place even if the work is tilted or displaced.

Adjustments can be made using the gray-scale data so that differences in brightness can allow accurate corrections. With multiple and priority functions, complex adjustments are also greatly simplified.

*A210 = rotational position adjustment function (X/Y/θ)

A110 = position adjustment function (X/Y)

■Rotational adjustment (A210)

Rotation correction

5Improved binary processing function

AA wide range of inspection functions

•Position/size/attitude/size detection with optimum feature extraction labeling.

•Presence/size/orientation inspection with optimum binary window functions.

•High-speed dimension measurements with optimum edge detection functions.

•High-speed length/number/presence inspections with optimum line functions.

| | mounts | | | | | Reject location |

| | | | | |

| | | | | | | lit up. |

Bearing inspection. | Gear tooth inspection. | LED lighting inspection. |

| Free shape | | | | | |

B | | | Inspection area |

| |

| | | | | | | |

This gives you accurate inspection even in cases where matching processing alone would fail.

Template | Matching detection | Differential result |

- | = | No |

difference |

=OK |

FMultiple position detection

Supports the multiple detection function with matching to allow the separate detection of multiple objects of the

Multiple position detection.

precisely for reduced time. |

Rotation |

With the affine transform function, the image will be rotated so that even if the work is tilted, setting and changes

CImage filter function.

Even with binary images containing substantial noise, stable image processing is possible using filter processing such as [image erosion] → [image dilation].

The filter functions will differ depending on the inspection

CSmart template (A210).

Just by showing multiple examples of the correct products, correct product images can be automatically composed. This allows simple inspection without setting complex parameters.

Smart template

GTeaching function.

Teaching allows changes to be made to the template for matching even from an external signal. Registering the change can be done simply by showing the object for detection.

Teaching also supports positional corrections so that even when work is displaced, teaching can occur.

Teaching with the touch of a button.

| | | | | | | | |

| | | | | ▲Filter/width function | |

| ▲No filter/width function | | |

| | | | | | | |

Inspection | Erroneous detection | Dirt is ignored |

position offset | because of dirt | | | | |

Filter/width function reduces chance of erroneous influence due to dirt or noise.

| | | | | | | | | | | | | | | Not processed |

| | | | | | | | | | | | | | | Noise erase |

| | | Pixel | | Eroded parts are not processed | After erosion, dilated parts are processed |

Original binary image. | 3 ⋅ 3 image dilation | 3 ⋅ 3 image erosion |

| | Image with erosion to |

| | dilation filtering |

| | Processing occurs |

| Dilated parts are processed. | After dilation, eroded parts are not processed |

Edge positions are measured accurately at the sub-pixel level. Also supports an edge counting function. Also equipped with the projection scanning formula so that the required edge position is detected even with products with a poor surface. With rotational correction, diagonal scanning performs sub-pixel edge detection with the gray-scale inter-pixel compensating function.

■Projection scanning edge detection

Averaged

Averaged

Pitch calculated by number of pins

Since the average value for brightness within the area is quickly calculated, directional distinction can still occur even when binary distinction is difficult due to the small differences in the gray-scale levels. You can set mask processing with free shapes (rectangular, oval, polygonal) set to match the inspected object.

GW1 GW2 GW3 GW4

When the direction is correct:

| Direction: OK | Direction: Reject | GW1 becomes brighter than GW2, so |

| GW1 - GW2 > 0 and GW3 - GW4 = 0. |

| | |

A | Supports 96 numerical | | | B | Leeway in judgement calculations | |

| calculation formulas (48 on the A110) | Even | for complex pass/fail judgement | |

Includes sine, cos, | | | | outputs, internal judgment formulae can be | |

| | | made without using the external PLC. | |

square root, arctan | | | | |

| | | Depending on the application, Judgement | |

absolute differential and | | | | |

| | | output can be set for individual and general | |

projection distance | | | | |

| | | judgement for each inspection area freely as | |

functions in addition to | | | | |

| | | desired. | | |

addition, subtraction, | | | | | |

| | | | | | Judgement output formula |

multiplication and | | | | | | |

division, and you can set | Calculating distances | | | | Internal judgement calculations | External judgement calculations | Total |

up to 96 formulas (48 for | | A210 | 96 formulae | 96 formulae | 192 formulae |

and angles | | |

the A110). You can also | | | A110 | 48 formulae | 48 formulae | 96 formulae |

| | |

reference up to 16 items | | | | | | | | |

per formula for complex | | New calculation formula | | |

calculations. | | | copy function | | | |

| | | | | | |

(also compatible with judgment formulas)

CProgramless data

transfer to the PLC

Using the Matsushita Electric Works. FP-series PLC, the Mitsubishi MELSEC A/FX series PLC, the Omron SYSMAC C series PLC, or the Allen- Bradley SLC 500 PLC (Ver. 2.2 or later), numerical calculation result data and judgement output results can be automatically written to the data register of the PLC at a maximum baud rate of 115200 bps. The image processing data can be used with the I/O sensitivity of the PLC.