FP-X series

Multi-point PID control

Higher accuracy is obtained by ultra

The simultaneous

The

By combining with a sequence control, the parameters (Kp, Ti, Td, etc.) can be changed during a PID control execution, thereby enabling optimum temperature control in each stage including start up,

*1 Derivative type

*2

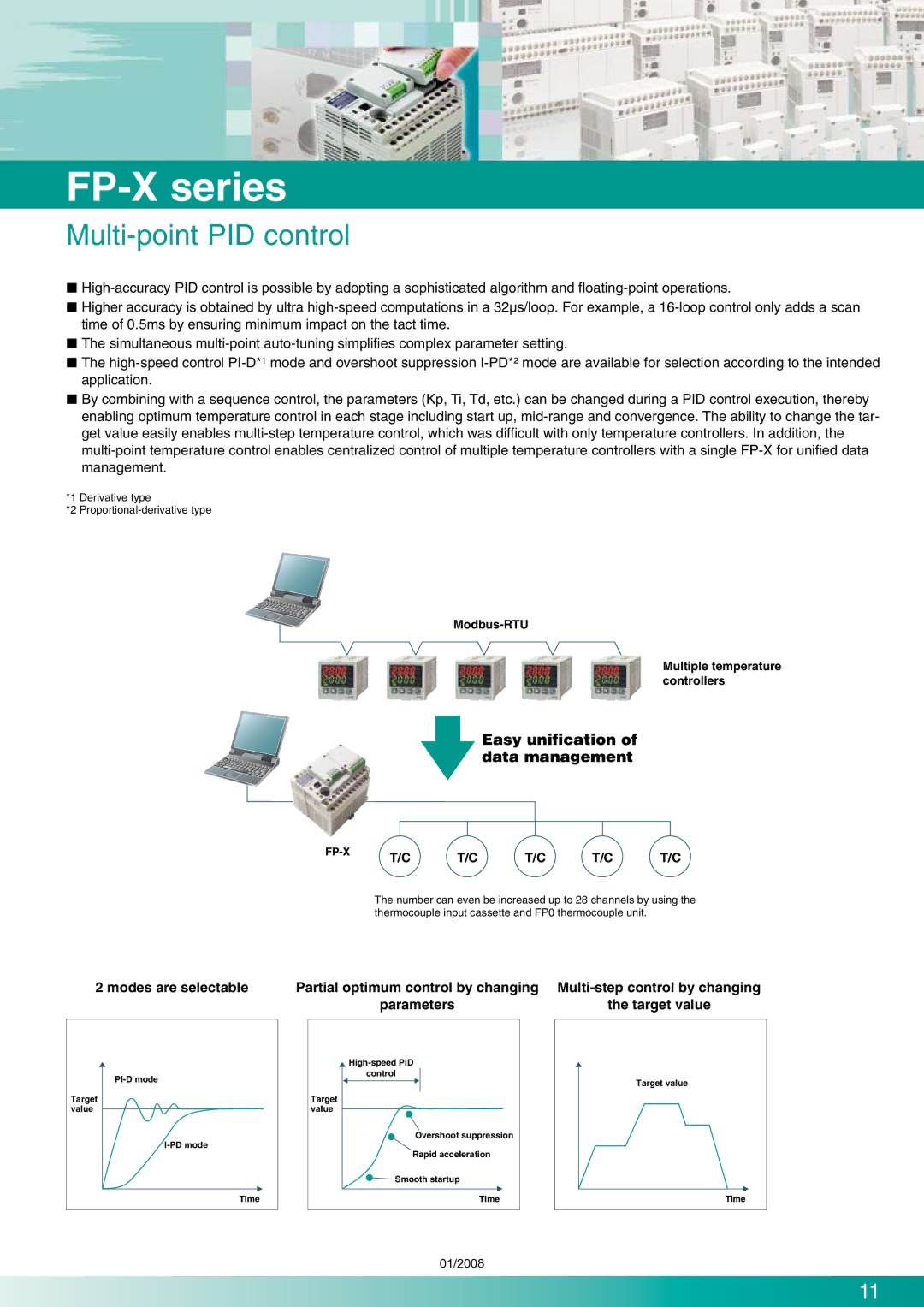

Multiple temperature controllers

Easy unification of data management

| T/C | T/C | T/C | T/C | T/C |

|

The number can even be increased up to 28 channels by using the thermocouple input cassette and FP0 thermocouple unit.

2 modes are selectable

Partial optimum control by changing | |

parameters | the target value |

Target |

value |

Time |

control |

Target |

value |

Overshoot suppression |

Rapid acceleration |

Smooth startup |

Time |

01/2008 |

Target value |

Time |

11