Service Adjustments and Calibrations

Service Adjustments and Calibrations

TEST EQUIPMENT

To do all of these electrical adjustments, the following equipment is required:

•

Voltage Range: 0.001 V to 50 V/Div.

Frequency Range: DC to 50 MHz

Probes: 10:1, 1:1

•NTSC Video Pattern Generator

•DVM (Digital Volt Meter)

•MTS/SAP Signal Generator

•(TV

•Plastic Tip Driver and

•Isolation Transformer (Variable)

•Degaussing Coil

•White Pattern Generator

•Audio Generator

ANODE AND HEATER VOLTAGE CONFIRMATION

1. PREPARATION:

1.1. Receive a crosshatch pattern.

2.2. Adjust the bunch current in zero. (0 beam)

3.3. Adjust “SCREEN VR” and “CONTRAST” to minimum.

2. CONFIRMATION:

2.1.Connect a voltage meter between TPA12 and ground. Confirm that the voltage +B is within a range of 140.5V± 1.5V

2.2.Connect a high frequency voltage meter (VRMS.) among the heater, and confirm that the reads tension is within a range of 6.3

± 0.24 (VRMS)

2.3.Connect the high voltage meter in the CRT anode pin, and confirm that the high voltage is within a range of [A]:

•

•

AGC RF CALIBRATION

1. PREPARATION:

1.1.Receive a color bar pattern and assure a RF input signal of 75Ω opened, channel 13 (211.25 MHz).

1.2.Connect the digital multimeter in TPA 15.

2. CALIBRATION:

2.1.Select the option “RF AGC” in the “CHK2” service mode.

2.2.Adjust RF AGC to 2.2±0.1V in TPA20.

3.3.Increase the input level by +2 dB and confirm that the voltage decrease.

Tuner | ENV56D75G3R | |

|

|

|

Level | 69dB mV | 69dB mV |

|

|

|

VIF DETECTOR OUTPUT LEVEL CONFIRMATION

1. CALIBRATION:

1.1.Install the chassis in the VIF calibration JIG and receive a color bar pattern with 63 dBU (75Ω opened).

1.2.Connect the oscilloscope to TPA33.

1.3.Confirm that the video output signal is within a range of 1.05

± 0.15

BUZZ (SOUND CIRCUIT)

1. PREPARATION:

1.1.Connect the oscilloscope with a 7kHz filter between TPA41 and ground or between the speaker’s terminals

1.2.Adjust the sound volume to the maximum.

1.3.Set “TONE” to “NORMAL” and “AVL” turned off.

2. CONFIRMATION:

2.1.Receive a color bar pattern channel 2, with local frequency adjusted and the AFC turned on (Channel with sound bearer and without modulation).

2.2.Assure that the width in the buzzing waveform is smaller than

500 m

PAL COLOR OUTPUT SIGNAL ADJUSTMENT

1. PREPARATION:

1.1.Receive a color bar pattern and adjust the local frequency.

1.2.Adjust “IMAGE” to DYNAMIC NORMAL, “CONTRAST” to 63 and

1.3.Adjust the “COLOR FOR CHANNEL” level to NORMAL.

1.4.Set the CHK2 service mode option, press “5” on the remote control unit and confirm that OSD becomes blue (AKB turned off).

1.5.Connect a short circuit jumper between TPA10 and TPA20.

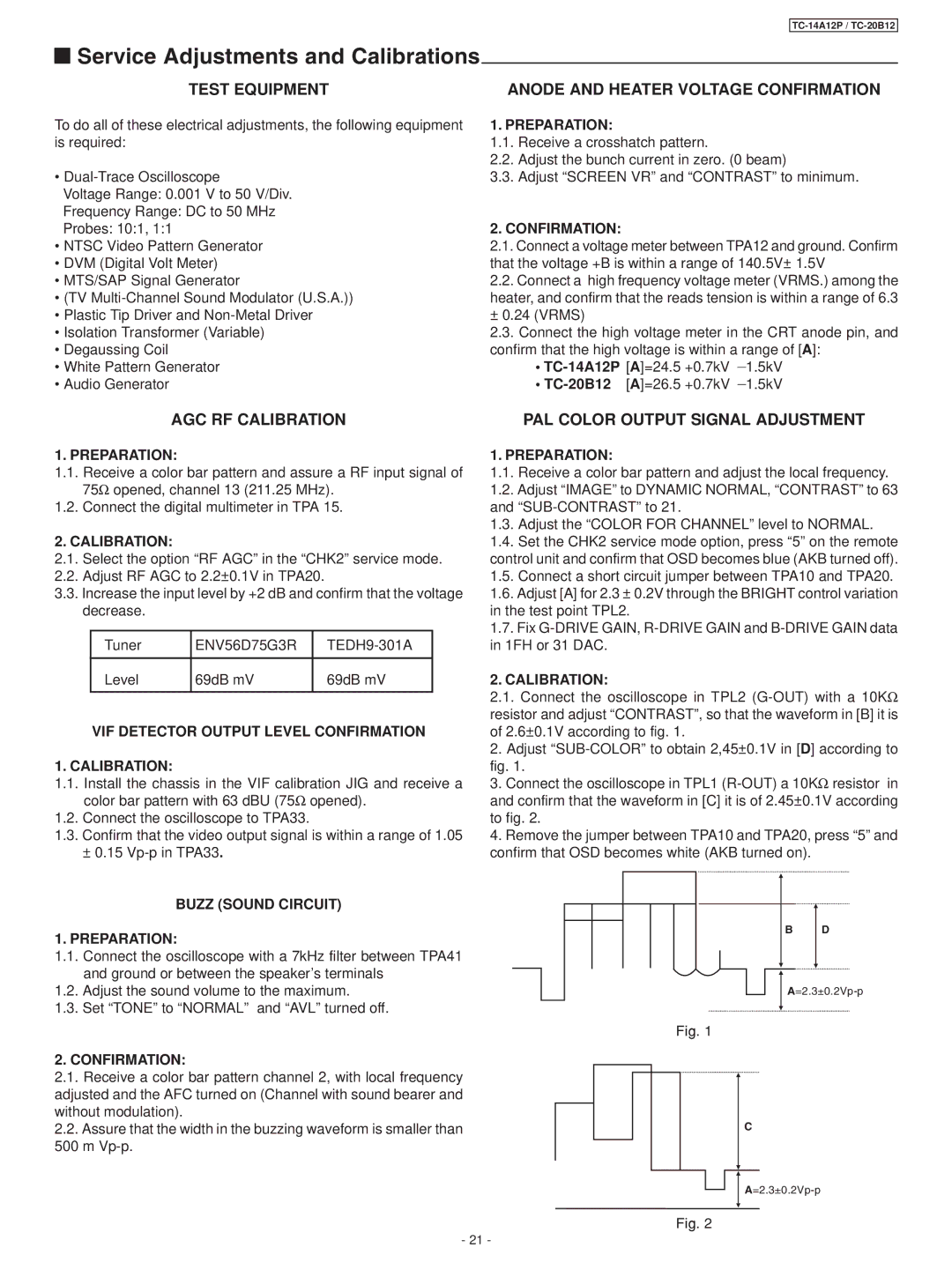

1.6.Adjust [A] for 2.3 ± 0.2V through the BRIGHT control variation in the test point TPL2.

1.7.Fix

2. CALIBRATION:

2.1.Connect the oscilloscope in TPL2

2. Adjust

fig. 1.

3. Connect the oscilloscope in TPL1

4. Remove the jumper between TPA10 and TPA20, press “5” and confirm that OSD becomes white (AKB turned on).

B | D |

|

|

Fig. 1

C

Fig. 2

- 21 -