16 HD65 & HD130 STEPPER DRIVES USER GUIDE

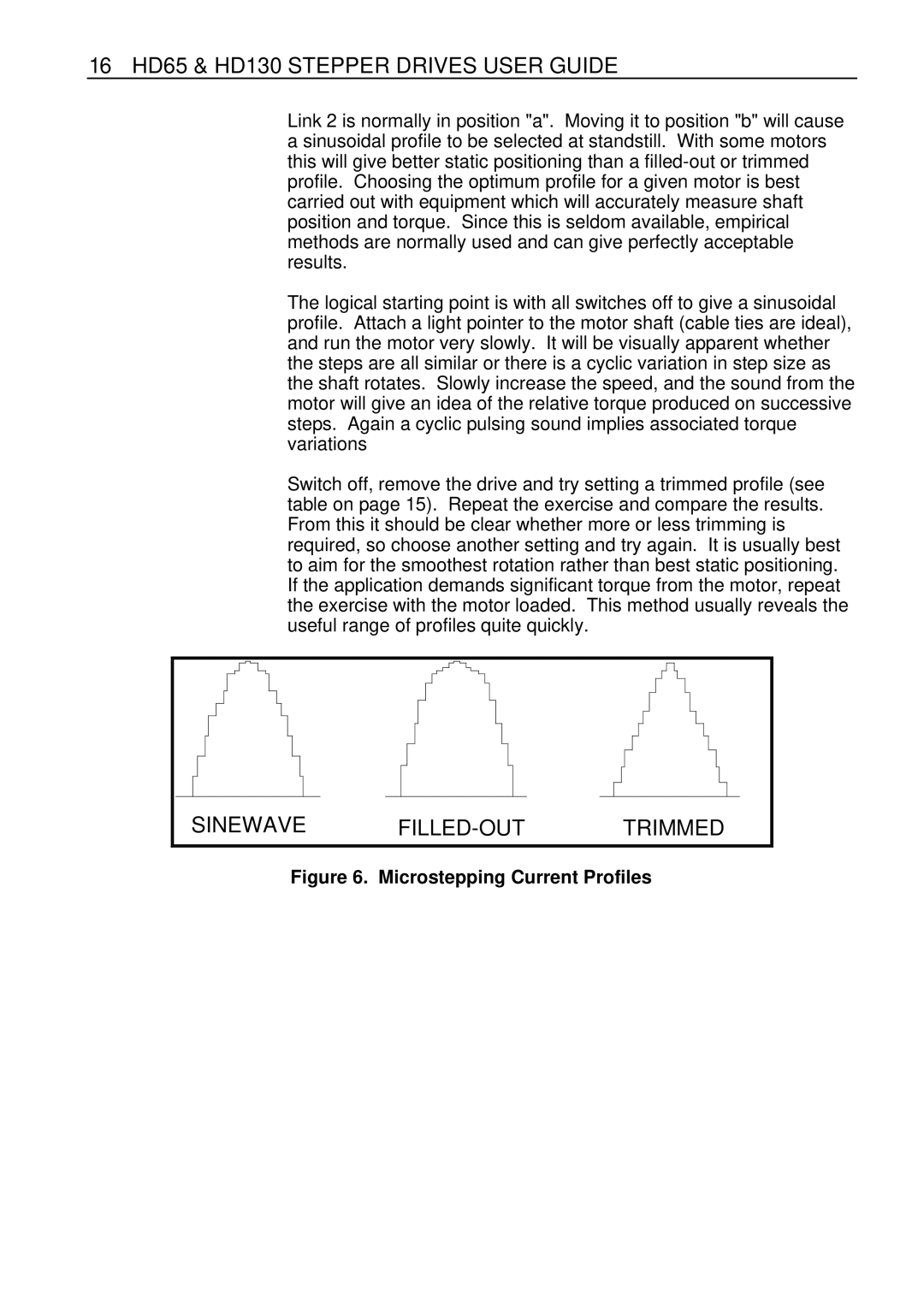

Link 2 is normally in position "a". Moving it to position "b" will cause a sinusoidal profile to be selected at standstill. With some motors this will give better static positioning than a

The logical starting point is with all switches off to give a sinusoidal profile. Attach a light pointer to the motor shaft (cable ties are ideal), and run the motor very slowly. It will be visually apparent whether the steps are all similar or there is a cyclic variation in step size as the shaft rotates. Slowly increase the speed, and the sound from the motor will give an idea of the relative torque produced on successive steps. Again a cyclic pulsing sound implies associated torque variations

Switch off, remove the drive and try setting a trimmed profile (see table on page 15). Repeat the exercise and compare the results. From this it should be clear whether more or less trimming is required, so choose another setting and try again. It is usually best to aim for the smoothest rotation rather than best static positioning. If the application demands significant torque from the motor, repeat the exercise with the motor loaded. This method usually reveals the useful range of profiles quite quickly.