NOTE: Adjustment points (socket screws) are factory torqued for optimal performance. This factory torque setting is recommended to prevent the screen from slipping over time. If more or less tension is desired follow this optional step. You may not achieve optimal torque value if factory torque settings are adjusted.

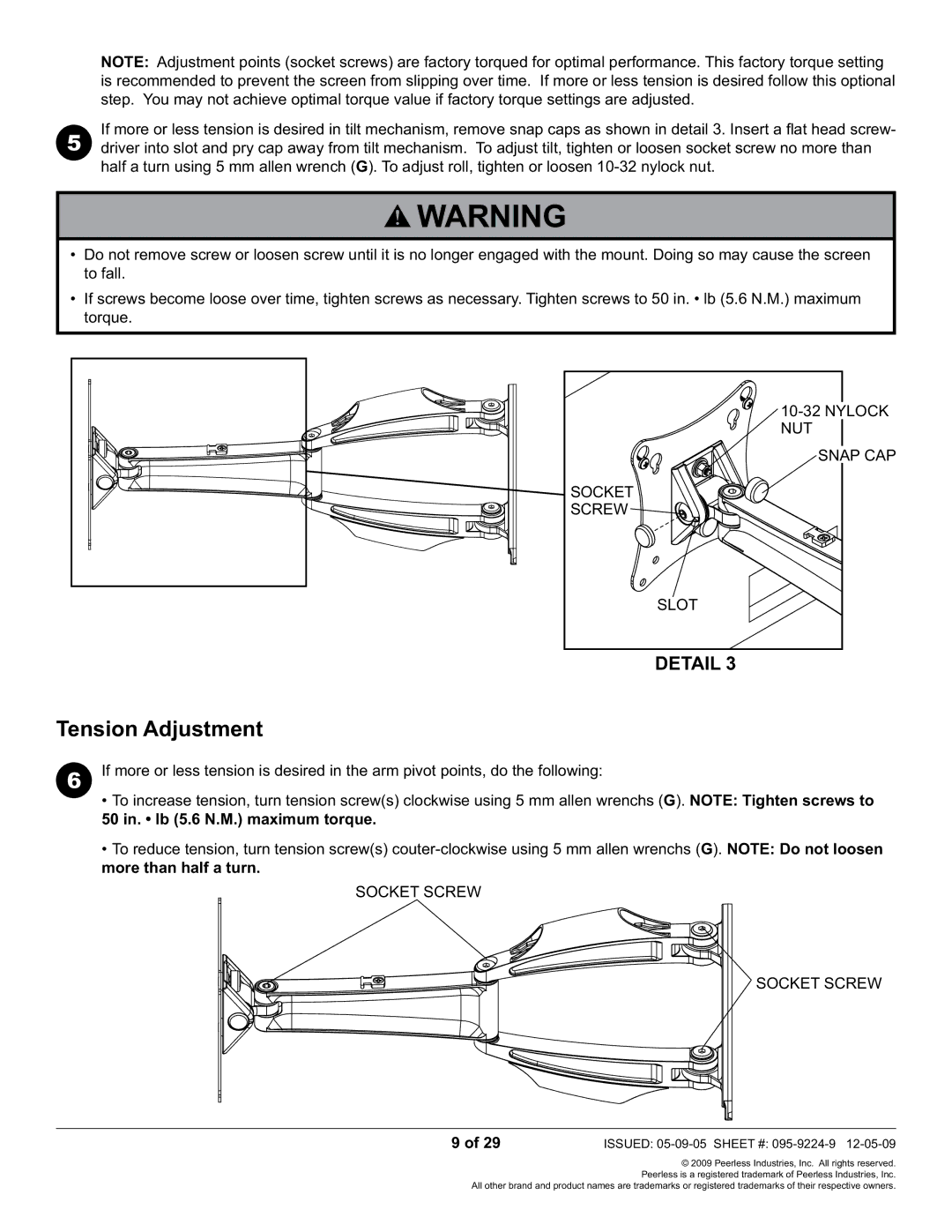

If more or less tension is desired in tilt mechanism, remove snap caps as shown in detail 3. Insert a flat head screw-

5driver into slot and pry cap away from tilt mechanism. To adjust tilt, tighten or loosen socket screw no more than half a turn using 5 mm allen wrench (G). To adjust roll, tighten or loosen

![]() WARNING

WARNING

•Do not remove screw or loosen screw until it is no longer engaged with the mount. Doing so may cause the screen to fall.

•If screws become loose over time, tighten screws as necessary. Tighten screws to 50 in. • lb (5.6 N.M.) maximum torque.

10-32 NYLOCK NUT

SNAP CAP

SOCKET

SCREW ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

SLOT

DETAIL 3

Tension Adjustment

6If more or less tension is desired in the arm pivot points, do the following:

•To increase tension, turn tension screw(s) clockwise using 5 mm allen wrenchs (G). NOTE: Tighten screws to 50 in. • lb (5.6 N.M.) maximum torque.

•To reduce tension, turn tension screw(s)

SOCKET SCREW

SOCKET SCREW

9 of 29 | ISSUED: |

© 2009 Peerless Industries, Inc. All rights reserved. Peerless is a registered trademark of Peerless Industries, Inc.

All other brand and product names are trademarks or registered trademarks of their respective owners.