![]() C

C

C

B

A

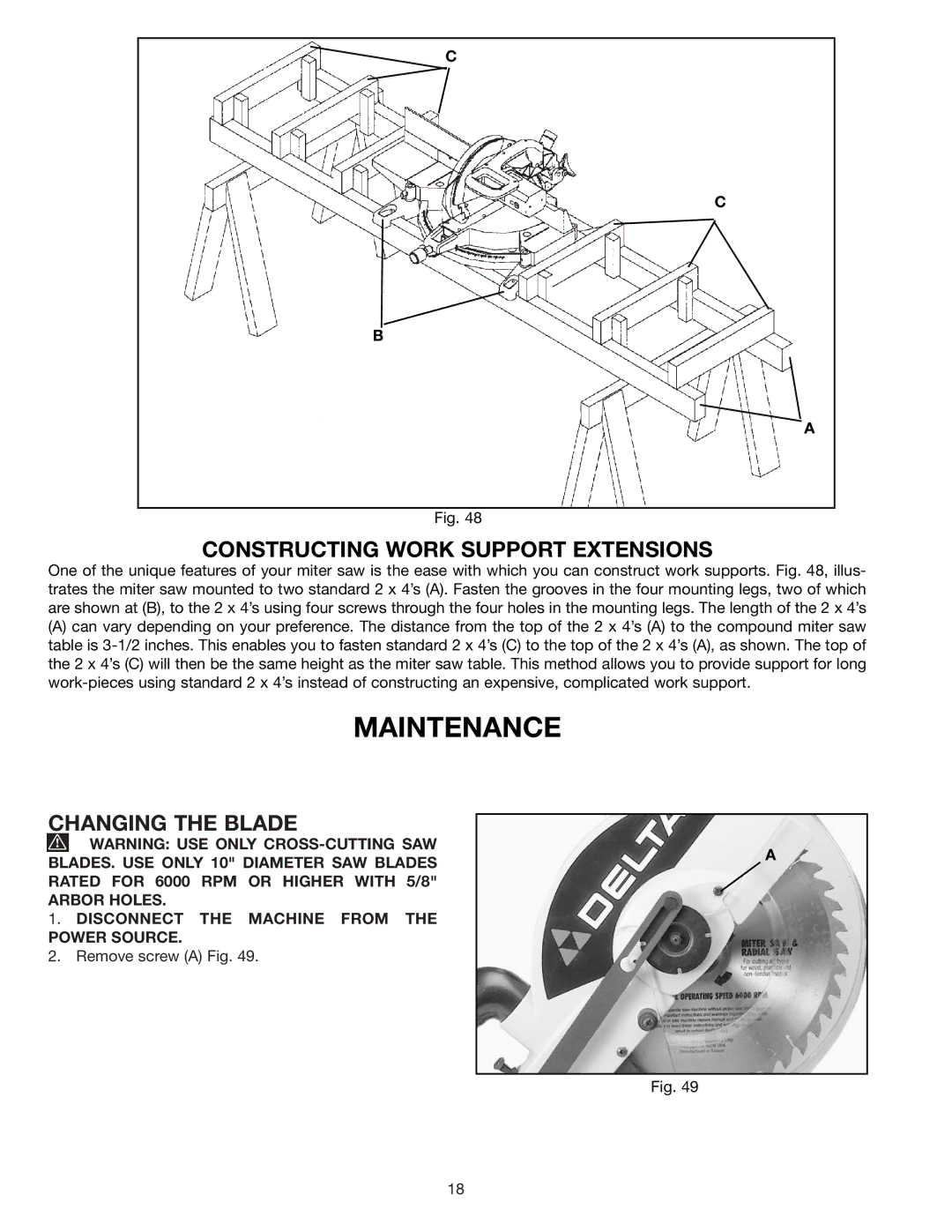

Fig. 48

CONSTRUCTING WORK SUPPORT EXTENSIONS

One of the unique features of your miter saw is the ease with which you can construct work supports. Fig. 48, illus- trates the miter saw mounted to two standard 2 x 4’s (A). Fasten the grooves in the four mounting legs, two of which are shown at (B), to the 2 x 4’s using four screws through the four holes in the mounting legs. The length of the 2 x 4’s

(A)can vary depending on your preference. The distance from the top of the 2 x 4’s (A) to the compound miter saw table is

MAINTENANCE

CHANGING THE BLADE

![]() WARNING: USE ONLY

WARNING: USE ONLY

ARBOR HOLES.

1.DISCONNECT THE MACHINE FROM THE POWER SOURCE.

2.Remove screw (A) Fig. 49.

A

Fig. 49

18