ADJUSTING SLIDING FIT BETWEEN TRUNNION AND BEVEL BRACKET

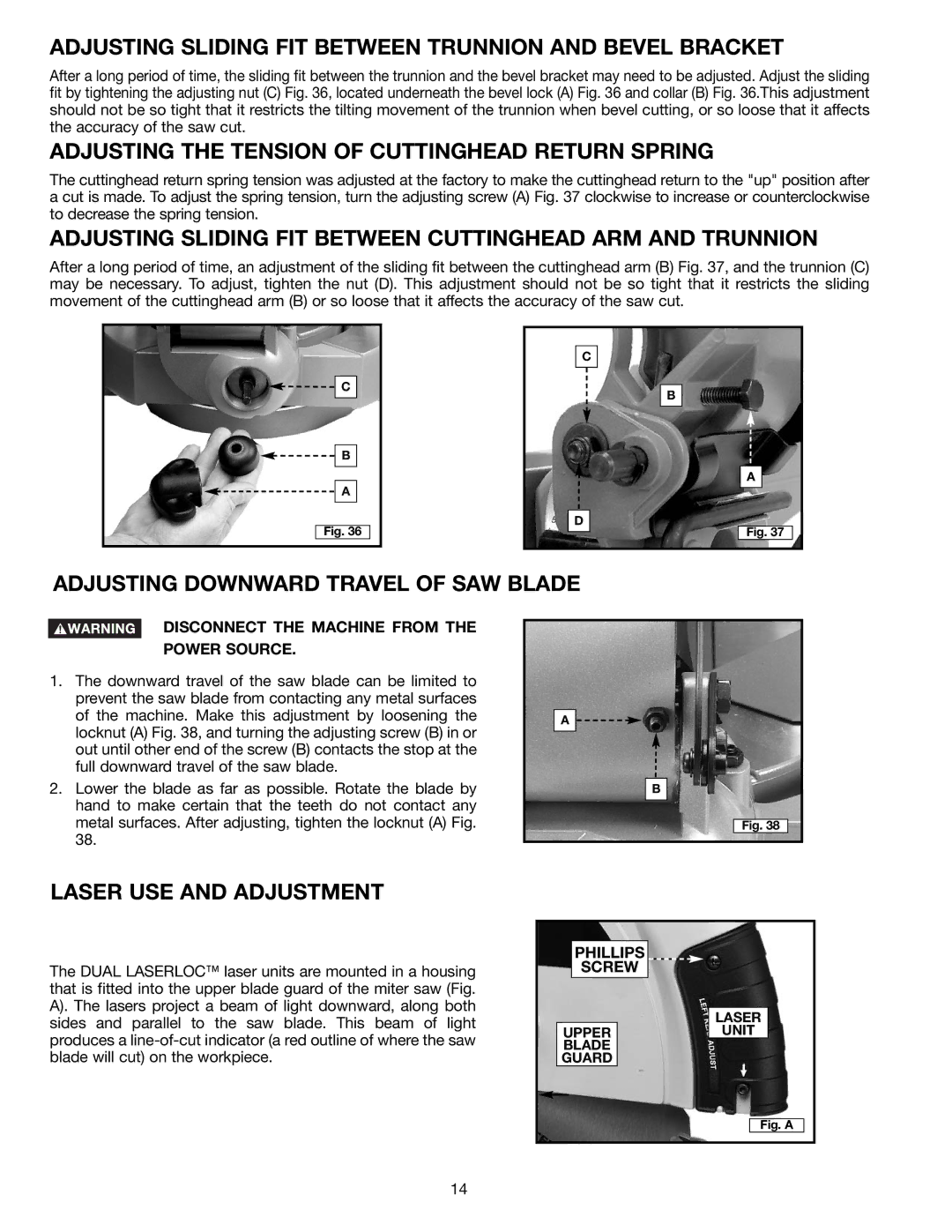

After a long period of time, the sliding fit between the trunnion and the bevel bracket may need to be adjusted. Adjust the sliding fit by tightening the adjusting nut (C) Fig. 36, located underneath the bevel lock (A) Fig. 36 and collar (B) Fig. 36.This adjustment should not be so tight that it restricts the tilting movement of the trunnion when bevel cutting, or so loose that it affects the accuracy of the saw cut.

ADJUSTING THE TENSION OF CUTTINGHEAD RETURN SPRING

The cuttinghead return spring tension was adjusted at the factory to make the cuttinghead return to the "up" position after a cut is made. To adjust the spring tension, turn the adjusting screw (A) Fig. 37 clockwise to increase or counterclockwise to decrease the spring tension.

ADJUSTING SLIDING FIT BETWEEN CUTTINGHEAD ARM AND TRUNNION

After a long period of time, an adjustment of the sliding fit between the cuttinghead arm (B) Fig. 37, and the trunnion (C) may be necessary. To adjust, tighten the nut (D). This adjustment should not be so tight that it restricts the sliding movement of the cuttinghead arm (B) or so loose that it affects the accuracy of the saw cut.

![]()

![]()

![]() C

C

![]()

![]()

![]() B

B

![]()

![]()

![]() A

A

Fig. 36

C

B

A

D

Fig. 37

ADJUSTING DOWNWARD TRAVEL OF SAW BLADE

DISCONNECT THE MACHINE FROM THE

POWER SOURCE.

1.The downward travel of the saw blade can be limited to prevent the saw blade from contacting any metal surfaces of the machine. Make this adjustment by loosening the locknut (A) Fig. 38, and turning the adjusting screw (B) in or out until other end of the screw (B) contacts the stop at the full downward travel of the saw blade.

2.Lower the blade as far as possible. Rotate the blade by hand to make certain that the teeth do not contact any metal surfaces. After adjusting, tighten the locknut (A) Fig. 38.

A ![]()

![]()

![]()

B

Fig. 38

LASER USE AND ADJUSTMENT

The DUAL LASERLOC™ laser units are mounted in a housing that is fitted into the upper blade guard of the miter saw (Fig. A). The lasers project a beam of light downward, along both sides and parallel to the saw blade. This beam of light produces a

PHILLIPS |

|

SCREW |

|

| LASER |

UPPER | UNIT |

BLADE |

|

GUARD |

|

| Fig. A |

14