To Drain Tank

Risk of Unsafe Operation. Risk from noise. Air tanks contain high pressure air. Keep face and other body parts away from outlet of drain. Use ANSI Z87.1 eye protection (CAN/CSA Z94.3) when drain-

ing as debris can be kicked up into face.

Risk from noise. Use ear protection [(ANSI S12.6 (S3.19) hearing protection] as air flow noise is loud when draining.

1.Set the On/Off switch to "Off".

2.Turn the regulator knob

3.Remove the air tool or accessory.

4.Pull ring on safety valve allowing air to bleed from the tank until tank pressure is approximately 20 PSI. Release safety valve ring.

5.Drain water from air tank by opening drain valve on bottom of tank.

Risk of Bursting. Water will condense in the air tank. If not drained, water will corrode and weaken the air tank causing

a risk of air tank rupture.

Risk of Property Damage. Drain water from air tank may contain oil and rust which can cause stains.

6.After the water has been drained, close the drain valve. The air compressor can now be stored.

NOTE: If drain valve is plugged, release all air pressure. The valve can then be removed, cleaned, the reinstalled.

SERVICE AND ADJUSTMENTS

ALL MAINTENANCE AND REPAIR OPERATIONS NOT LISTED MUST BE PERFORMED BY TRAINED SERVICE TECHNICIAN.

Risk of Unsafe Operation. Unit cycles automatically when ![]() power is on. When servicing, you may be exposed to volt- age sources, compressed air, or moving parts. Before servicing unit unplug

power is on. When servicing, you may be exposed to volt- age sources, compressed air, or moving parts. Before servicing unit unplug

or disconnect electrical supply to the air compressor, bleed tank of pressure, and allow the air compressor to cool.

To Replace or Clean Check Valve

1.Release all air pressure from air tank. See "To Drain Tank" in the Maintenance section.

2.Unplug unit.

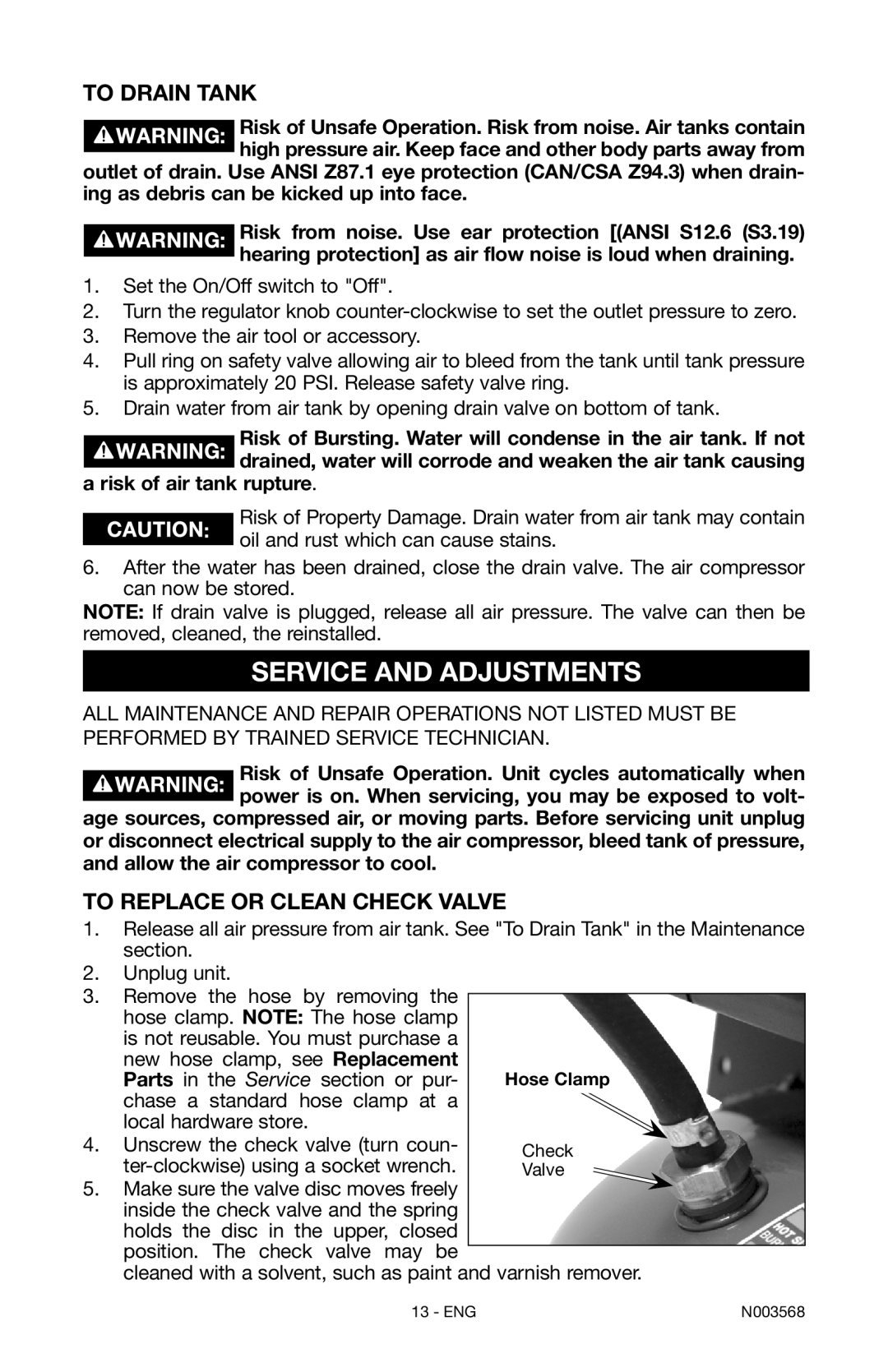

3.Remove the hose by removing the hose clamp. NOTE: The hose clamp is not reusable. You must purchase a

new hose clamp, see Replacement |

|

Parts in the Service section or pur- | Hose Clamp |

chase a standard hose clamp at a |

|

| |

local hardware store. |

|

4. Unscrew the check valve (turn coun- | Check |

Valve |

5. Make sure the valve disc moves freely inside the check valve and the spring holds the disc in the upper, closed position. The check valve may be

cleaned with a solvent, such as paint and varnish remover.

13 - ENG | N003568 |