bar tip. A

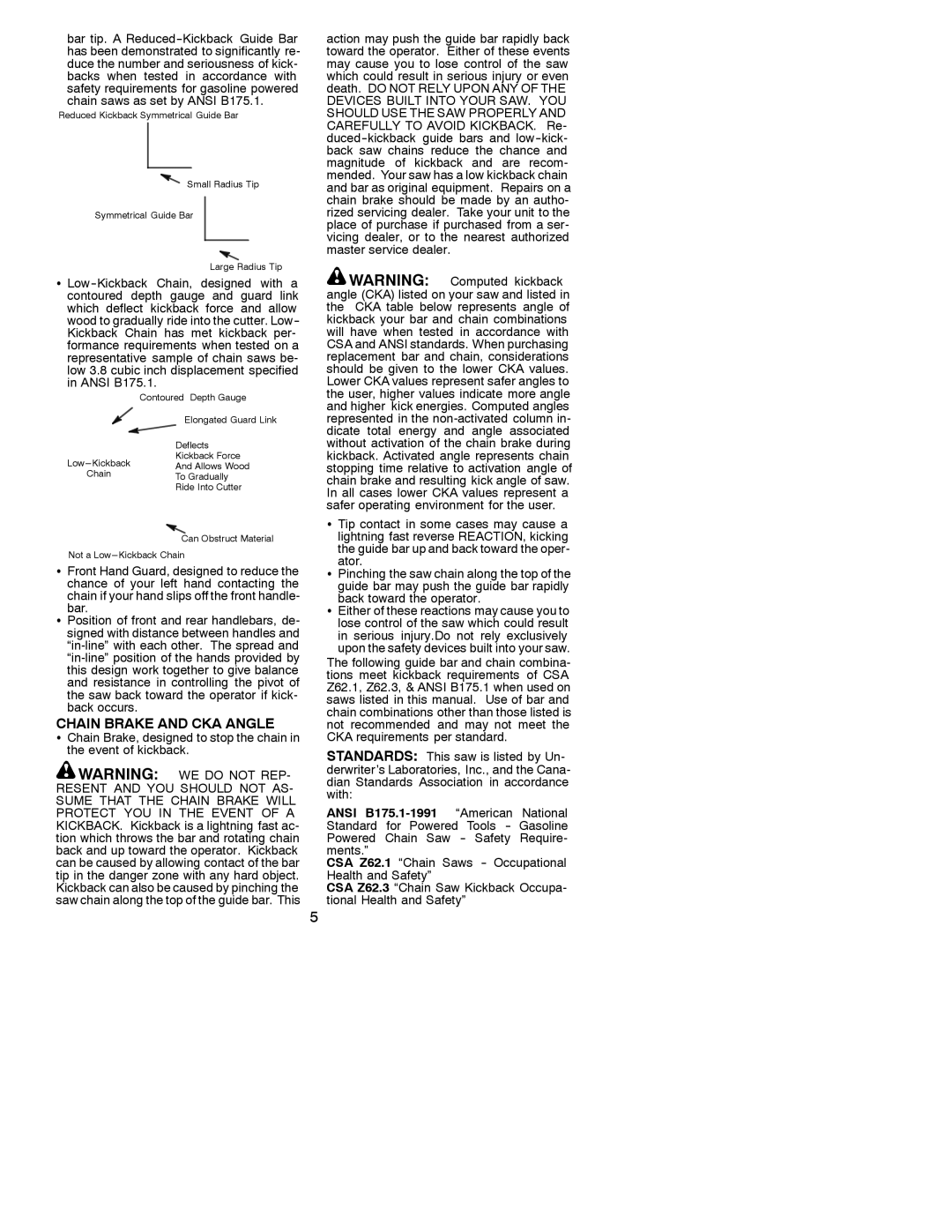

Reduced Kickback Symmetrical Guide Bar

Small Radius Tip

Symmetrical Guide Bar

Large Radius Tip

S

Contoured Depth Gauge

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Elongated Guard Link | ||

|

|

|

|

|

|

|

|

|

|

|

| Deflects | ||||||

Kickback Force | ||||||||||||||||||

And Allows Wood | ||||||||||||||||||

Chain | ||||||||||||||||||

To Gradually | ||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

| Ride Into Cutter | ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Can Obstruct Material | |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

Not a

SFront Hand Guard, designed to reduce the chance of your left hand contacting the chain if your hand slips off the front handle- bar.

SPosition of front and rear handlebars, de- signed with distance between handles and

CHAIN BRAKE AND CKA ANGLE

SChain Brake, designed to stop the chain in the event of kickback.

![]() WARNING: WE DO NOT REP- RESENT AND YOU SHOULD NOT AS- SUME THAT THE CHAIN BRAKE WILL PROTECT YOU IN THE EVENT OF A KICKBACK. Kickback is a lightning fast ac- tion which throws the bar and rotating chain back and up toward the operator. Kickback can be caused by allowing contact of the bar tip in the danger zone with any hard object. Kickback can also be caused by pinching the saw chain along the top of the guide bar. This

WARNING: WE DO NOT REP- RESENT AND YOU SHOULD NOT AS- SUME THAT THE CHAIN BRAKE WILL PROTECT YOU IN THE EVENT OF A KICKBACK. Kickback is a lightning fast ac- tion which throws the bar and rotating chain back and up toward the operator. Kickback can be caused by allowing contact of the bar tip in the danger zone with any hard object. Kickback can also be caused by pinching the saw chain along the top of the guide bar. This

action may push the guide bar rapidly back toward the operator. Either of these events may cause you to lose control of the saw which could result in serious injury or even death. DO NOT RELY UPON ANY OF THE DEVICES BUILT INTO YOUR SAW. YOU SHOULD USE THE SAW PROPERLY AND CAREFULLY TO AVOID KICKBACK. Re-

![]() WARNING: Computed kickback angle (CKA) listed on your saw and listed in the CKA table below represents angle of kickback your bar and chain combinations will have when tested in accordance with CSA and ANSI standards. When purchasing replacement bar and chain, considerations should be given to the lower CKA values. Lower CKA values represent safer angles to the user, higher values indicate more angle and higher kick energies. Computed angles represented in the

WARNING: Computed kickback angle (CKA) listed on your saw and listed in the CKA table below represents angle of kickback your bar and chain combinations will have when tested in accordance with CSA and ANSI standards. When purchasing replacement bar and chain, considerations should be given to the lower CKA values. Lower CKA values represent safer angles to the user, higher values indicate more angle and higher kick energies. Computed angles represented in the

S Tip contact in some cases may cause a lightning fast reverse REACTION, kicking the guide bar up and back toward the oper- ator.

SPinching the saw chain along the top of the guide bar may push the guide bar rapidly back toward the operator.

SEither of these reactions may cause you to lose control of the saw which could result in serious injury.Do not rely exclusively upon the safety devices built into your saw.

The following guide bar and chain combina- tions meet kickback requirements of CSA Z62.1, Z62.3, & ANSI B175.1 when used on saws listed in this manual. Use of bar and chain combinations other than those listed is not recommended and may not meet the CKA requirements per standard.

STANDARDS: This saw is listed by Un- derwriter’s Laboratories, Inc., and the Cana- dian Standards Association in accordance with:

ANSI

CSA Z62.1 “Chain Saws

CSA Z62.3 “Chain Saw Kickback Occupa- tional Health and Safety”

5