Tip of Bar |

|

|

|

| S | Using the screwdriver end of the bar tool, | |||||

|

|

|

|

| roll chain around guide bar to ensure all | ||||||

|

|

|

|

| |||||||

|

|

|

|

|

| links are in bar groove. | |||||

Proper chain direction |

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

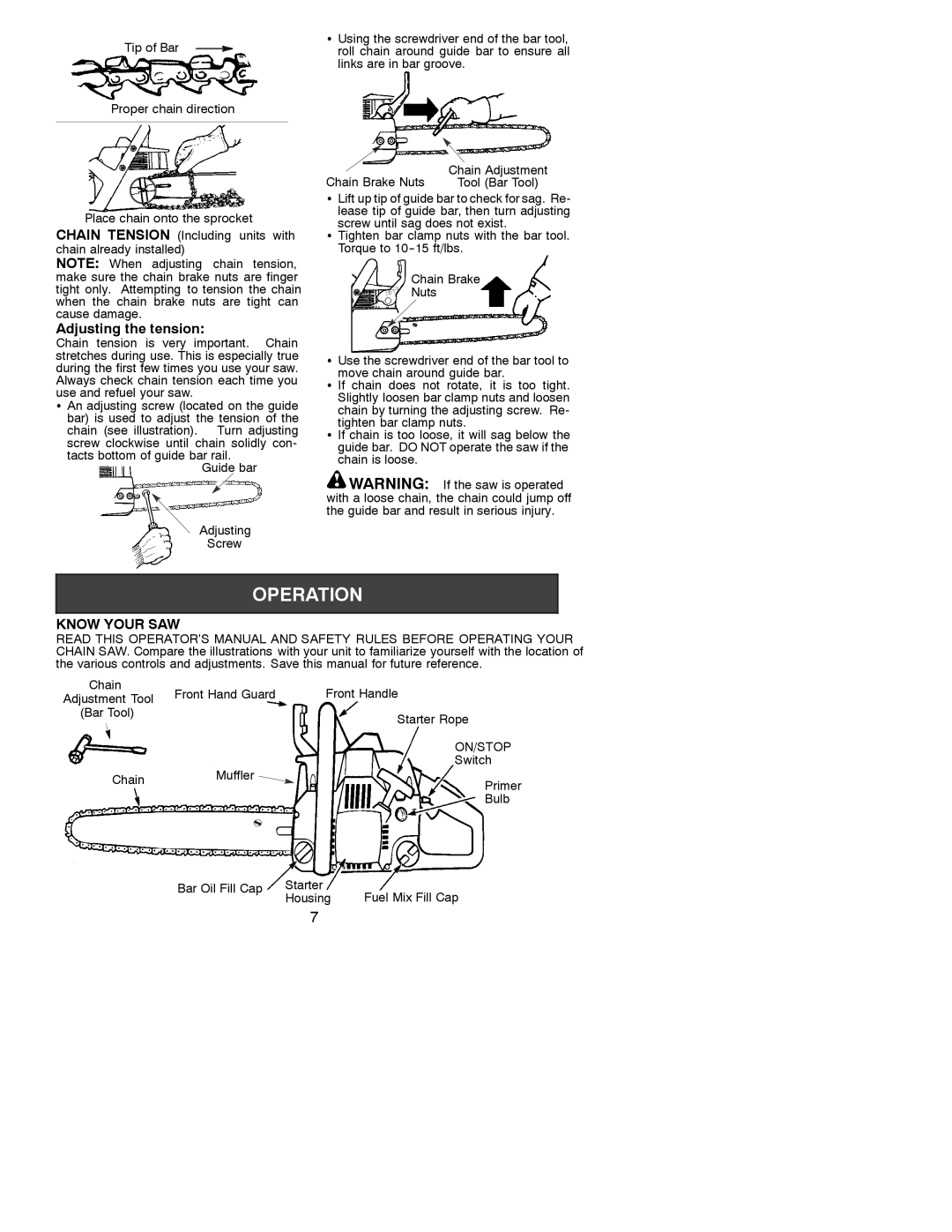

Place chain onto the sprocket

CHAIN TENSION (Including units with chain already installed)

NOTE: When adjusting chain tension, make sure the chain brake nuts are finger tight only. Attempting to tension the chain when the chain brake nuts are tight can cause damage.

Adjusting the tension:

Chain tension is very important. Chain stretches during use. This is especially true during the first few times you use your saw. Always check chain tension each time you use and refuel your saw.

SAn adjusting screw (located on the guide bar) is used to adjust the tension of the chain (see illustration). Turn adjusting screw clockwise until chain solidly con- tacts bottom of guide bar rail.

Guide bar

Adjusting

Screw

Chain Brake Nuts | Chain Adjustment |

Tool (Bar Tool) |

SLift up tip of guide bar to check for sag. Re- lease tip of guide bar, then turn adjusting screw until sag does not exist.

S Tighten bar clamp nuts with the bar tool. Torque to

![]() Chain Brake

Chain Brake ![]() Nuts

Nuts

SUse the screwdriver end of the bar tool to

move chain around guide bar.

S If chain does not rotate, it is too tight. Slightly loosen bar clamp nuts and loosen chain by turning the adjusting screw. Re- tighten bar clamp nuts.

SIf chain is too loose, it will sag below the guide bar. DO NOT operate the saw if the chain is loose.

![]() WARNING: If the saw is operated with a loose chain, the chain could jump off the guide bar and result in serious injury.

WARNING: If the saw is operated with a loose chain, the chain could jump off the guide bar and result in serious injury.

KNOW YOUR SAW

READ THIS OPERATOR’S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR CHAIN SAW. Compare the illustrations with your unit to familiarize yourself with the location of the various controls and adjustments. Save this manual for future reference.

Chain | Front Hand Guard |

|

| Front Handle | |||

Adjustment Tool |

|

| |||||

|

|

|

|

|

|

| |

(Bar Tool) |

|

|

|

|

| Starter Rope | |

|

|

|

|

|

| ||

|

|

|

|

|

| ON/STOP | |

|

|

|

|

|

| Switch | |

Chain | Muffler |

|

|

|

| ||

|

|

|

|

|

| Primer | |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| Bulb |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bar Oil Fill Cap Starter

Housing Fuel Mix Fill Cap

7