Method 2 uses a scrap board and calipers.

1.Turn on the digital display. It turns on in absolute mode.

2.Plane one side of a scrap board at an appropriate and safe cutting depth (1/16” for example).

3.Raise the table by the same amount (1/16”), then turn the board over and plane the other side. Do not move the table from the current position.

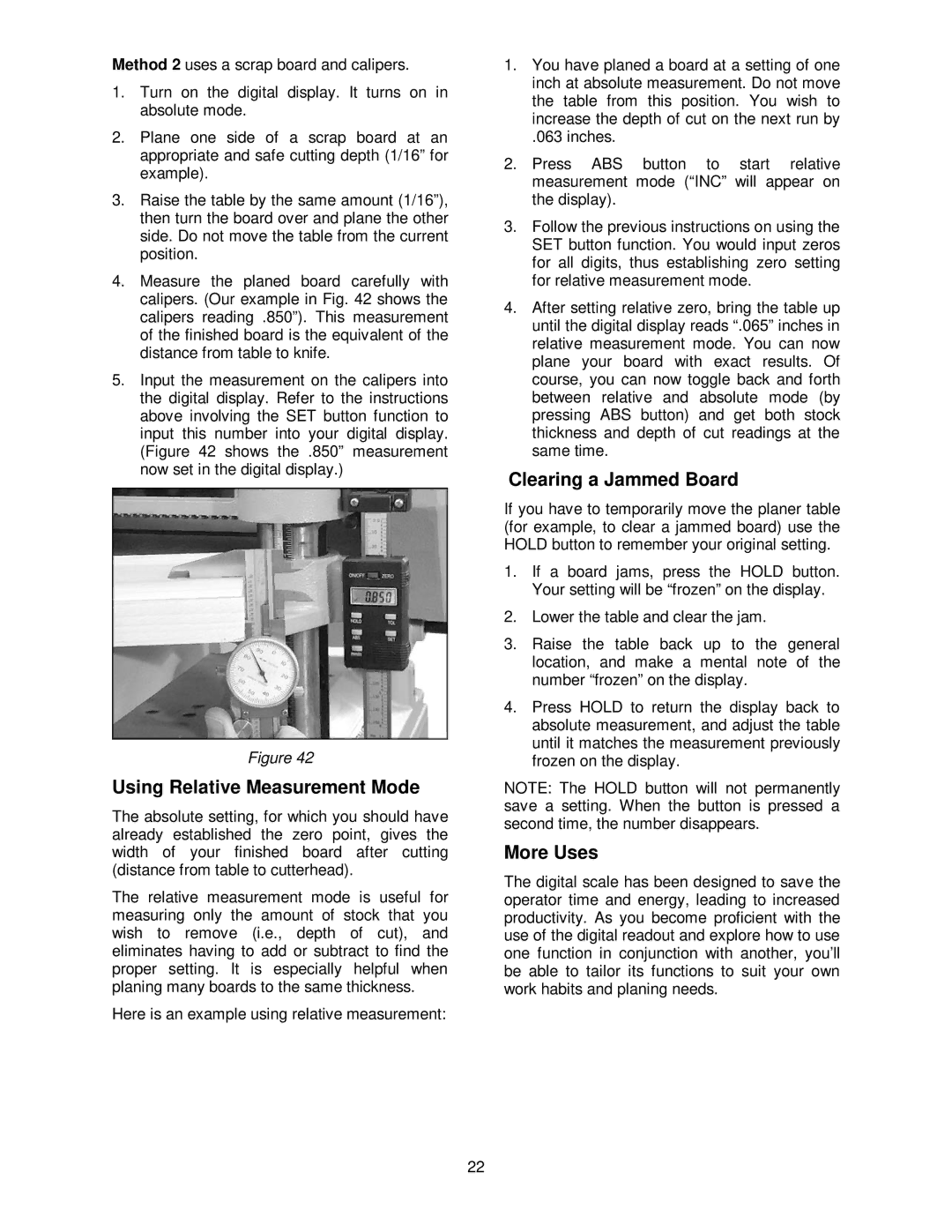

4.Measure the planed board carefully with calipers. (Our example in Fig. 42 shows the calipers reading .850”). This measurement of the finished board is the equivalent of the distance from table to knife.

5.Input the measurement on the calipers into the digital display. Refer to the instructions above involving the SET button function to input this number into your digital display. (Figure 42 shows the .850” measurement now set in the digital display.)

Figure 42

Using Relative Measurement Mode

The absolute setting, for which you should have already established the zero point, gives the width of your finished board after cutting (distance from table to cutterhead).

The relative measurement mode is useful for measuring only the amount of stock that you wish to remove (i.e., depth of cut), and eliminates having to add or subtract to find the proper setting. It is especially helpful when planing many boards to the same thickness.

Here is an example using relative measurement:

1.You have planed a board at a setting of one inch at absolute measurement. Do not move the table from this position. You wish to increase the depth of cut on the next run by

.063 inches.

2.Press ABS button to start relative measurement mode (“INC” will appear on the display).

3.Follow the previous instructions on using the SET button function. You would input zeros for all digits, thus establishing zero setting for relative measurement mode.

4.After setting relative zero, bring the table up until the digital display reads “.065” inches in relative measurement mode. You can now plane your board with exact results. Of course, you can now toggle back and forth between relative and absolute mode (by pressing ABS button) and get both stock thickness and depth of cut readings at the same time.

Clearing a Jammed Board

If you have to temporarily move the planer table (for example, to clear a jammed board) use the HOLD button to remember your original setting.

1.If a board jams, press the HOLD button. Your setting will be “frozen” on the display.

2.Lower the table and clear the jam.

3.Raise the table back up to the general location, and make a mental note of the number “frozen” on the display.

4.Press HOLD to return the display back to absolute measurement, and adjust the table until it matches the measurement previously frozen on the display.

NOTE: The HOLD button will not permanently save a setting. When the button is pressed a second time, the number disappears.

More Uses

The digital scale has been designed to save the operator time and energy, leading to increased productivity. As you become proficient with the use of the digital readout and explore how to use one function in conjunction with another, you’ll be able to tailor its functions to suit your own work habits and planing needs.

22