3.Continue to check the spacing by sliding the headstock across, until the dovetail cuts will be distributed evenly across the width of the workpiece. NOTE: This is an approximate method of determining by eye where to place the workpiece. A scale in inches and millimeters is mounted to the table if you need more precise measurements for the location of the dovetail cuts.

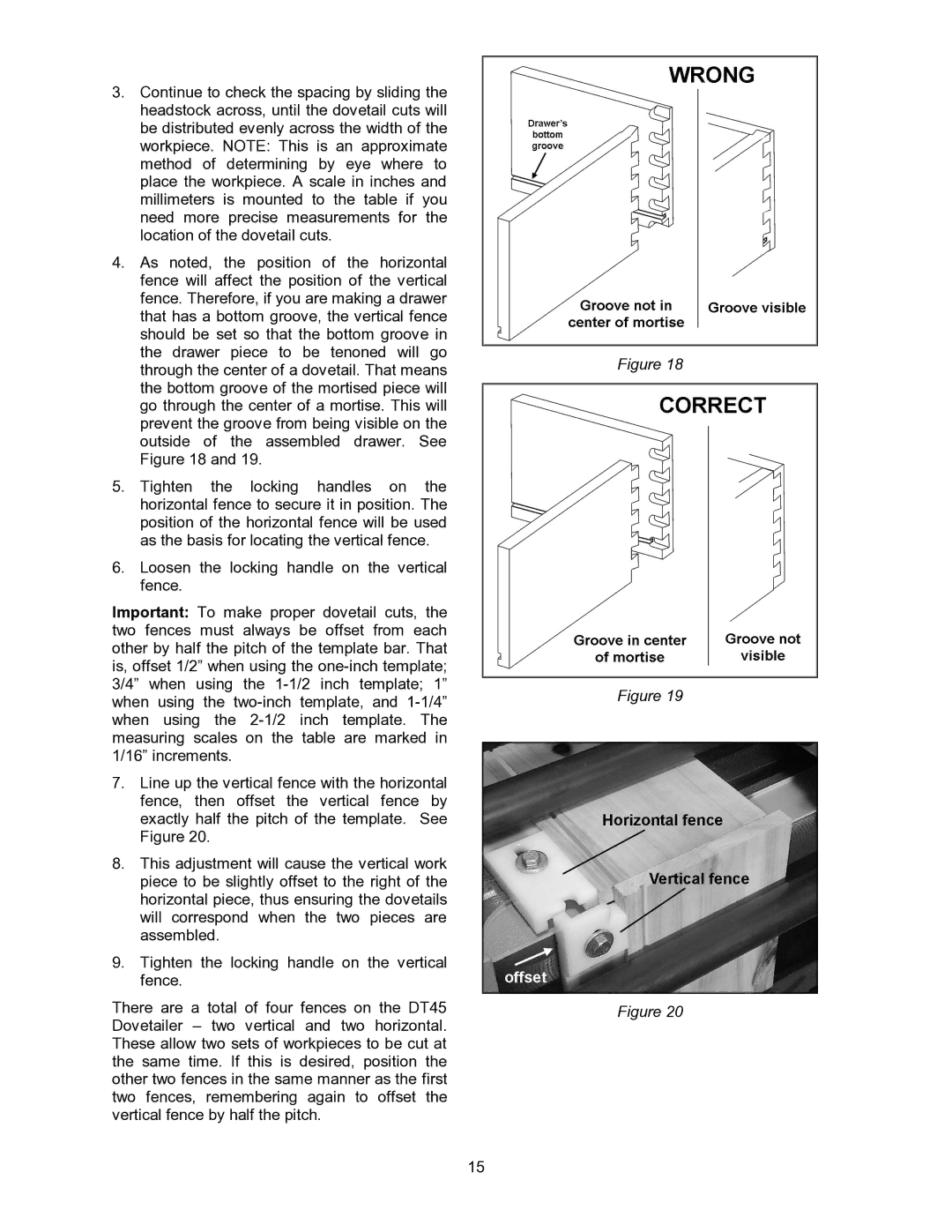

4.As noted, the position of the horizontal fence will affect the position of the vertical fence. Therefore, if you are making a drawer that has a bottom groove, the vertical fence should be set so that the bottom groove in the drawer piece to be tenoned will go through the center of a dovetail. That means the bottom groove of the mortised piece will go through the center of a mortise. This will prevent the groove from being visible on the outside of the assembled drawer. See Figure 18 and 19.

5.Tighten the locking handles on the horizontal fence to secure it in position. The position of the horizontal fence will be used as the basis for locating the vertical fence.

6.Loosen the locking handle on the vertical fence.

Important: To make proper dovetail cuts, the two fences must always be offset from each other by half the pitch of the template bar. That is, offset 1/2” when using the

7.Line up the vertical fence with the horizontal fence, then offset the vertical fence by exactly half the pitch of the template. See Figure 20.

8.This adjustment will cause the vertical work piece to be slightly offset to the right of the horizontal piece, thus ensuring the dovetails will correspond when the two pieces are assembled.

9.Tighten the locking handle on the vertical fence.

There are a total of four fences on the DT45 Dovetailer – two vertical and two horizontal. These allow two sets of workpieces to be cut at the same time. If this is desired, position the other two fences in the same manner as the first two fences, remembering again to offset the vertical fence by half the pitch.

15

Figure 18

Figure 19

Figure 20