10.Insert the LEFT SIDE piece and clamp it in vertical position on the lower work support and against the fence. (NOTE: The bottom grooves on both pieces will be face up, but will now be opposite the fences.) Again, make sure the edges are flush with the LEFT SIDE overlapping the edge of the BACK.

11.Continue the dovetailing procedure with the FRONT piece, making cuts “C” and “D” (Figure 25) until all four joints of the drawer have been cut.

TIP: When using drawer side widths that are not “whole inch” sizes, you may wish to gauge off the top of the drawer rather than the bottom when placing workpieces in the machine. Doing this will improve the look of the drawer by providing a full tenon near the top of the drawer and the

Preventing Chip Out

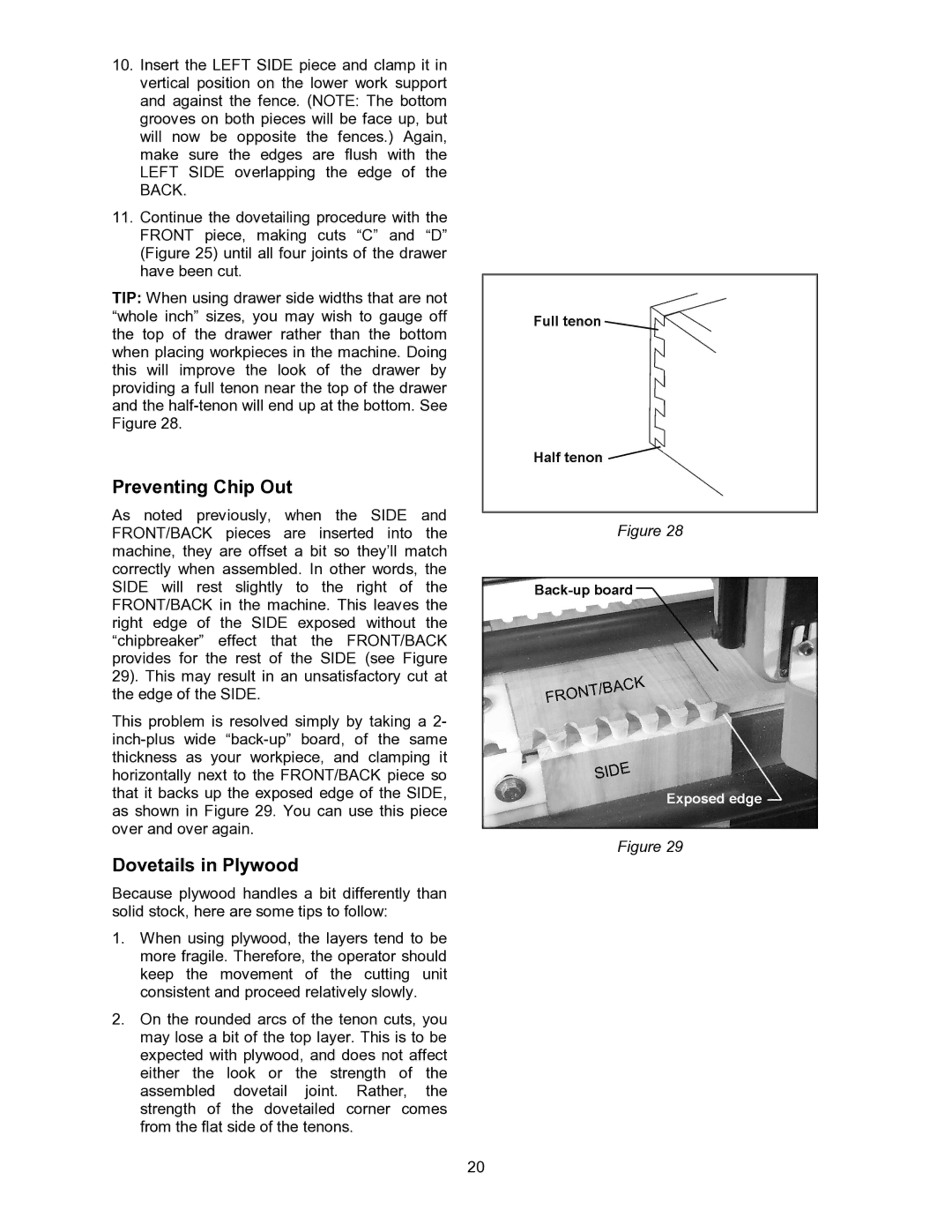

As noted previously, when the SIDE and FRONT/BACK pieces are inserted into the machine, they are offset a bit so they’ll match correctly when assembled. In other words, the SIDE will rest slightly to the right of the FRONT/BACK in the machine. This leaves the right edge of the SIDE exposed without the “chipbreaker” effect that the FRONT/BACK provides for the rest of the SIDE (see Figure 29). This may result in an unsatisfactory cut at the edge of the SIDE.

This problem is resolved simply by taking a 2-

Dovetails in Plywood

Because plywood handles a bit differently than solid stock, here are some tips to follow:

1.When using plywood, the layers tend to be more fragile. Therefore, the operator should keep the movement of the cutting unit consistent and proceed relatively slowly.

2.On the rounded arcs of the tenon cuts, you may lose a bit of the top layer. This is to be expected with plywood, and does not affect either the look or the strength of the assembled dovetail joint. Rather, the strength of the dovetailed corner comes from the flat side of the tenons.

Figure 28

Figure 29

20