Miter Gauge

A miter gauge is provided for crosscutting operations. Install the miter gauge by sliding the end of the miter gauge bar into the

To adjust the angle of the miter gauge:

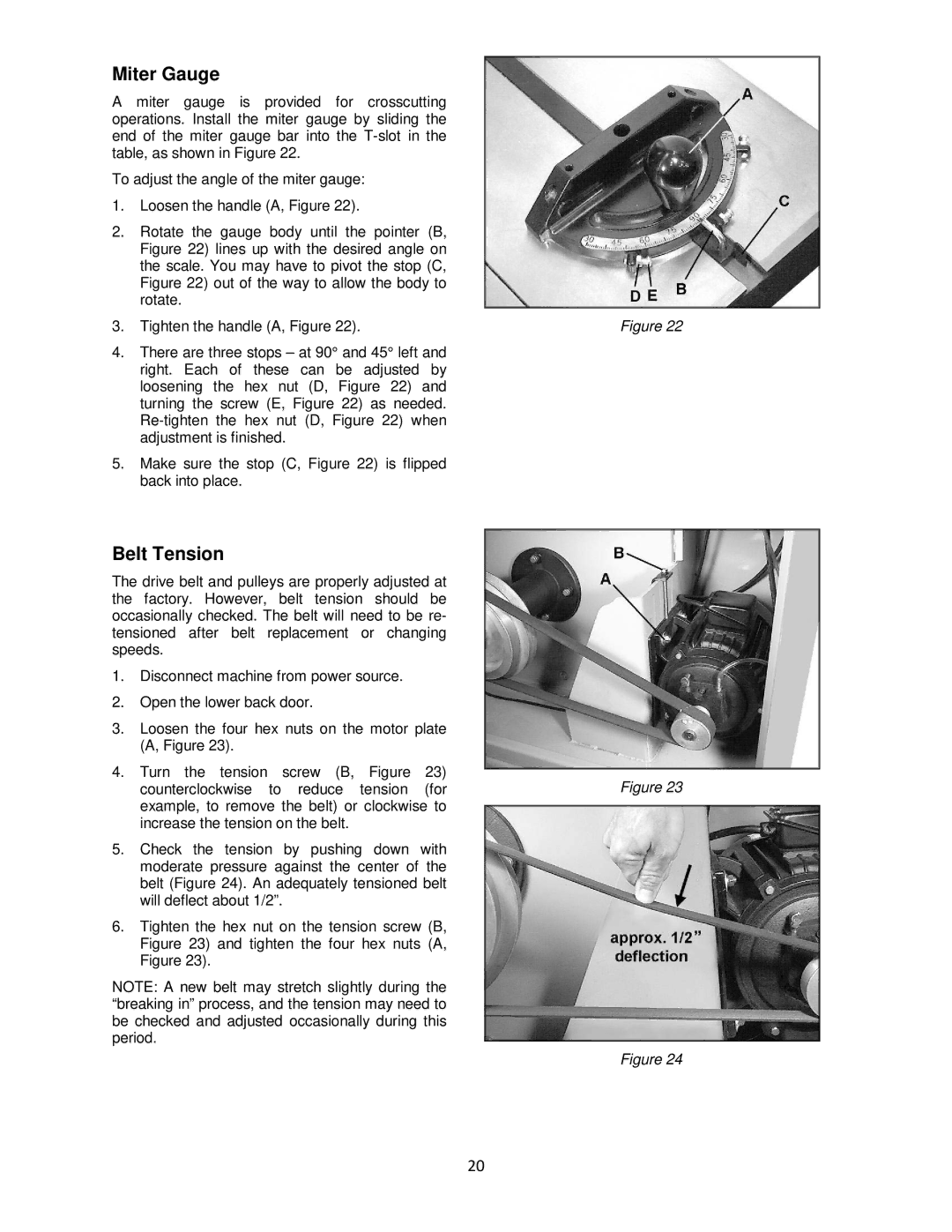

1.Loosen the handle (A, Figure 22).

2.Rotate the gauge body until the pointer (B, Figure 22) lines up with the desired angle on the scale. You may have to pivot the stop (C, Figure 22) out of the way to allow the body to rotate.

3.Tighten the handle (A, Figure 22).

4.There are three stops – at 90° and 45° left and right. Each of these can be adjusted by loosening the hex nut (D, Figure 22) and turning the screw (E, Figure 22) as needed.

5.Make sure the stop (C, Figure 22) is flipped back into place.

Belt Tension

The drive belt and pulleys are properly adjusted at the factory. However, belt tension should be occasionally checked. The belt will need to be re- tensioned after belt replacement or changing speeds.

1.Disconnect machine from power source.

2.Open the lower back door.

3.Loosen the four hex nuts on the motor plate (A, Figure 23).

4.Turn the tension screw (B, Figure 23) counterclockwise to reduce tension (for example, to remove the belt) or clockwise to increase the tension on the belt.

5.Check the tension by pushing down with moderate pressure against the center of the belt (Figure 24). An adequately tensioned belt will deflect about 1/2”.

6.Tighten the hex nut on the tension screw (B, Figure 23) and tighten the four hex nuts (A, Figure 23).

NOTE: A new belt may stretch slightly during the “breaking in” process, and the tension may need to be checked and adjusted occasionally during this period.

Figure 22

Figure 23

Figure 24

20