Ripping

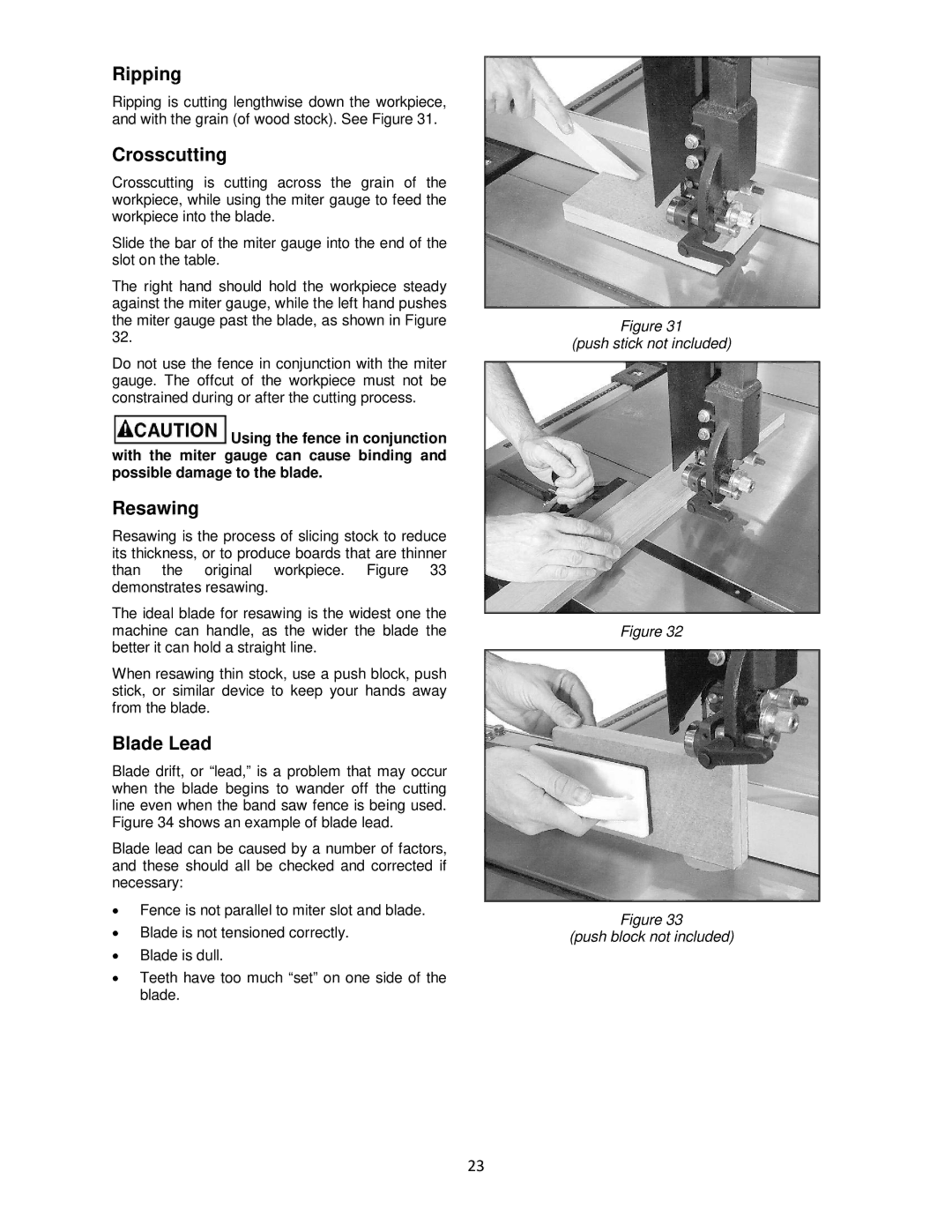

Ripping is cutting lengthwise down the workpiece, and with the grain (of wood stock). See Figure 31.

Crosscutting

Crosscutting is cutting across the grain of the workpiece, while using the miter gauge to feed the workpiece into the blade.

Slide the bar of the miter gauge into the end of the slot on the table.

The right hand should hold the workpiece steady against the miter gauge, while the left hand pushes the miter gauge past the blade, as shown in Figure 32.

Do not use the fence in conjunction with the miter gauge. The offcut of the workpiece must not be constrained during or after the cutting process.

![]() Using the fence in conjunction with the miter gauge can cause binding and possible damage to the blade.

Using the fence in conjunction with the miter gauge can cause binding and possible damage to the blade.

Resawing

Resawing is the process of slicing stock to reduce its thickness, or to produce boards that are thinner than the original workpiece. Figure 33 demonstrates resawing.

The ideal blade for resawing is the widest one the machine can handle, as the wider the blade the better it can hold a straight line.

When resawing thin stock, use a push block, push stick, or similar device to keep your hands away from the blade.

Blade Lead

Blade drift, or “lead,” is a problem that may occur when the blade begins to wander off the cutting line even when the band saw fence is being used. Figure 34 shows an example of blade lead.

Blade lead can be caused by a number of factors, and these should all be checked and corrected if necessary:

•Fence is not parallel to miter slot and blade.

•Blade is not tensioned correctly.

•Blade is dull.

•Teeth have too much “set” on one side of the blade.

Figure 31

(push stick not included)

Figure 32

Figure 33

(push block not included)

23