3.Tighten the handle (A, Figure 3). If necessary, move the Fence slightly to bring it parallel with the blade.

4.When satisfied, mark the location of the second hole using the hole in the Fence base as your template.

5.Remove the Fence from the table, and drill and tap the second hole.

6.Place the Fence over the hole pattern again, and secure the Fence to the table with two M10 x 30 hex cap screws and two M10 lock washers. Tighten firmly.

Mounting the Feeder

1.Screw the handle (Figure 4) all the way into the threaded hole of the Stock Feeder.

NOTE: If the mounting surface is narrow, a bracket (not provided) must be attached to support the Stock Feeder. Figure 5 shows an example.

![]() The Stock Feeder is heavy. Use a hoist during installation procedures. Failure to comply may cause injury!

The Stock Feeder is heavy. Use a hoist during installation procedures. Failure to comply may cause injury!

2.Figure 6 shows the proper method of lifting the Stock Feeder with a hoist. Place one end of the strap or rope around the motor mount and the other end around the handle, as shown.

3.Lift the Stock Feeder carefully into place over the hole pattern previously marked on the band saw table, and verify that the hole pattern lines up correctly with the holes in the Stock Feeder base.

4.Remove the Stock Feeder, and drill and tap the four holes.

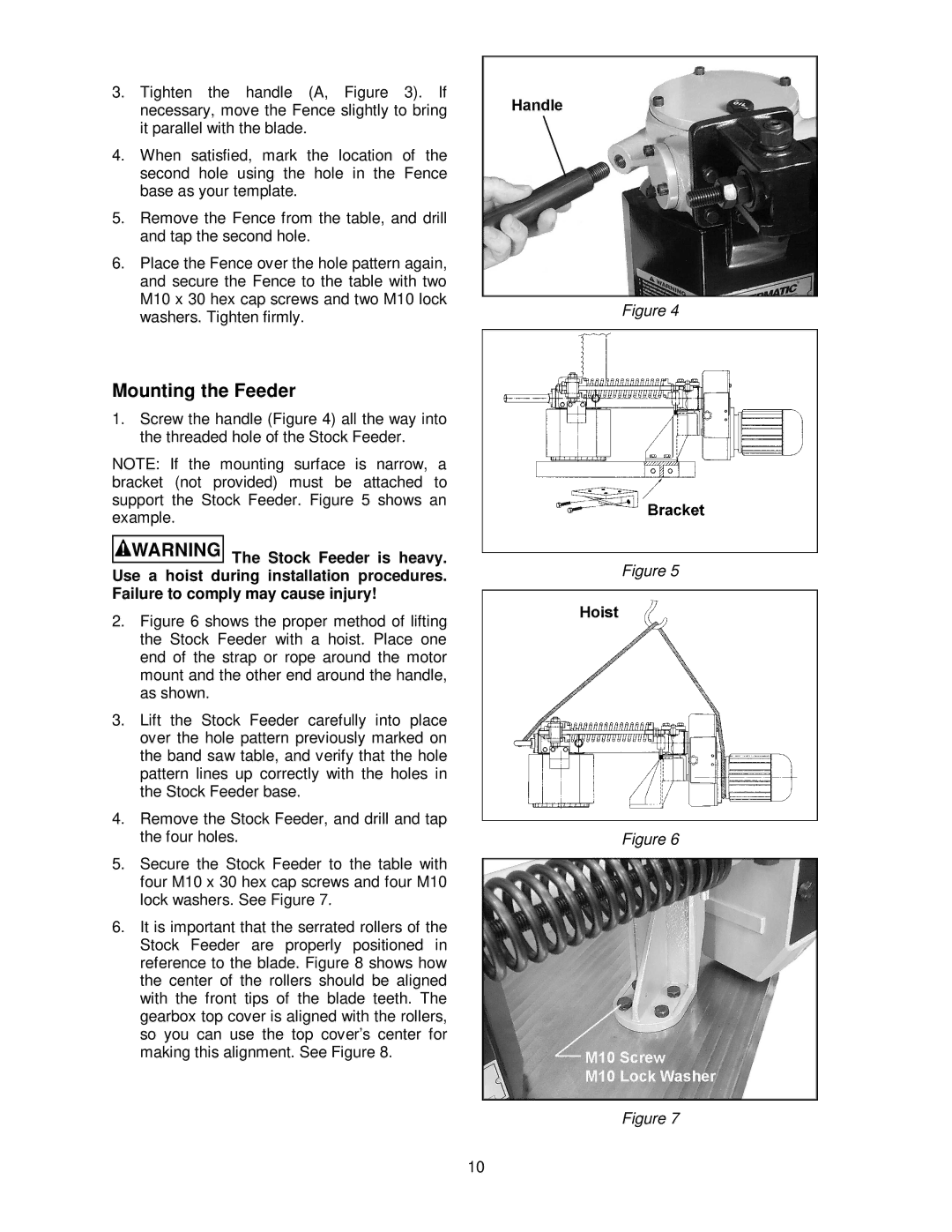

5.Secure the Stock Feeder to the table with four M10 x 30 hex cap screws and four M10 lock washers. See Figure 7.

6.It is important that the serrated rollers of the Stock Feeder are properly positioned in reference to the blade. Figure 8 shows how the center of the rollers should be aligned with the front tips of the blade teeth. The gearbox top cover is aligned with the rollers, so you can use the top cover’s center for making this alignment. See Figure 8.

10

Figure 4

Figure 5

Figure 6

Figure 7