2.Set the desired rate of feed on the Stock Feeder by moving the belt to the proper pulley grooves. Proper rate of feed will depend upon the hardness and thickness of the workpiece, and is best learned through experience.

3.Set the Fence so that the dimension on the scale (C, Figure 10) matches the desired thickness of the workpiece. Secure the Fence in position with the locking handle.

4.Turn on the band saw and the Stock Feeder, and carefully feed the workpiece through the blade.

NOTE: If a jam should occur while feeding, turn off the band saw and the Stock Feeder, pivot the Stock Feeder out of the way, and remove the workpiece. Return the Stock Feeder to position and begin the cut over again.

Maintenance

![]() Before performing any maintenance on the Stock Feeder, disconnect it from the electrical supply by pulling out the plug or switching off the breaker. Also make sure the band saw is disconnected from power. Failure to comply may cause serious injury.

Before performing any maintenance on the Stock Feeder, disconnect it from the electrical supply by pulling out the plug or switching off the breaker. Also make sure the band saw is disconnected from power. Failure to comply may cause serious injury.

If the power cord is worn, cut, or damaged in any way, have it replaced immediately.

Frequently blow out dust and chips from the Stock Feeder with compressed air.

Lubrication

Gearbox

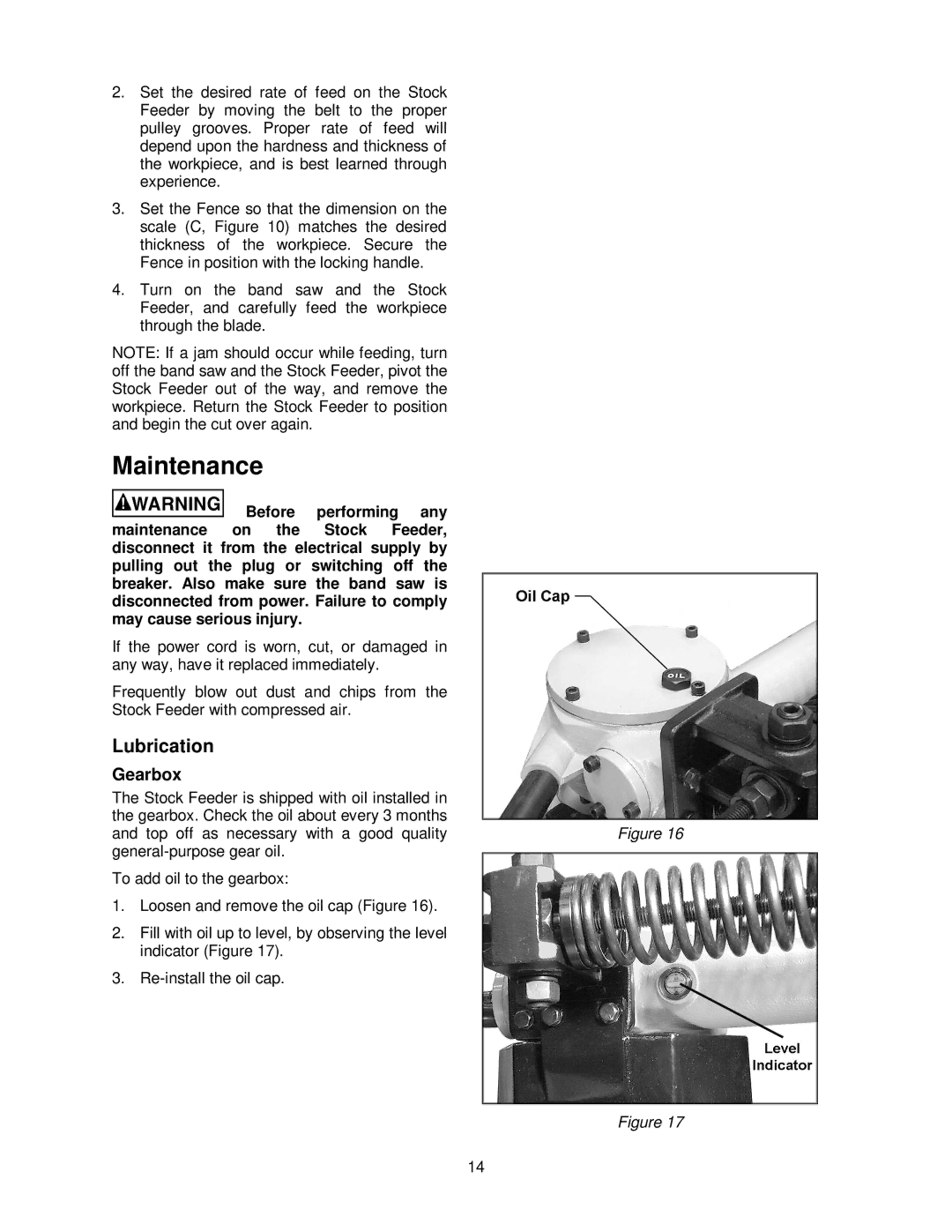

The Stock Feeder is shipped with oil installed in the gearbox. Check the oil about every 3 months and top off as necessary with a good quality

To add oil to the gearbox:

1.Loosen and remove the oil cap (Figure 16).

2.Fill with oil up to level, by observing the level indicator (Figure 17).

3.

Figure 16

Figure 17

14