TOC | INDEX |

Section 4: Troubleshooting and Maintenance

A. CLEANING THE PRINTER

It may be necessary to clean the ink cartridge nozzles if the your labels are printing with horizontal banding or if you suspect an ink cartridge nozzle has become slightly dried out or clogged.

Refer to the cleaning procedure explained within the Clean/ Purge description of Section

If any ink has gotten on to the printer casing itself, the case of the printer can be cleaned with an ammonia based window cleaner and a

Over time, ink overspray may gather at the base of the printer. The printer is designed using a vacuum system to gather most of this ink on a series of saturation pads. Eventually, these pads may need to be replaced. Contact tech support to determine if pad replacement is necessary. An ink pad replacement kit is available. (Part Number 074220)

B. BASIC TROUBLESHOOTING

Generally, when a malfunction or an abnormal condition occurs, the "PAUSE " LED will keep blinking repeatedly and printing and communication between the host PC and the

printer will cease.

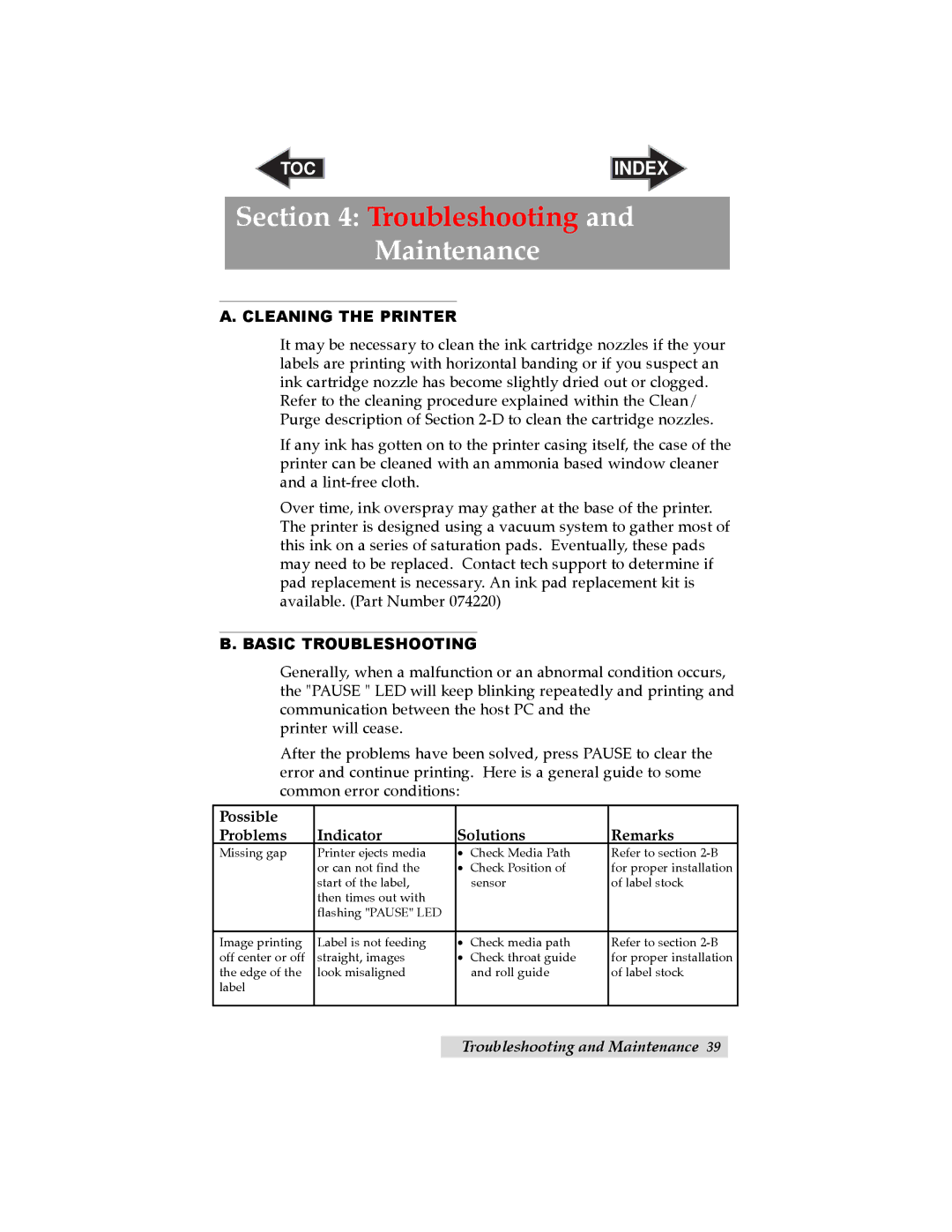

After the problems have been solved, press PAUSE to clear the error and continue printing. Here is a general guide to some common error conditions:

Possible |

|

|

|

|

Problems | Indicator | Solutions | Remarks | |

Missing gap | Printer ejects media | • | Check Media Path | Refer to section |

| or can not find the | • | Check Position of | for proper installation |

| start of the label, |

| sensor | of label stock |

| then times out with |

|

|

|

| flashing "PAUSE" LED |

|

|

|

|

|

|

|

|

Image printing | Label is not feeding | • | Check media path | Refer to section |

off center or off | straight, images | • | Check throat guide | for proper installation |

the edge of the | look misaligned |

| and roll guide | of label stock |

label |

|

|

|

|

|

|

|

|

|

Troubleshooting and Maintenance 39