R | CB 1200 Pellet Stove |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9 |

|

| With proper installation, operation, and maintenance your appliance will provide years | |||

|

|

|

|

| ||

|

|

|

|

| of | |

|

|

| Troubleshooting | will assist a qualified service person in the diagnosis of a problem and the corrective | ||

|

|

| action to be taken. This troubleshooting guide can only be used by a qualified service | |||

|

|

|

|

| technician. |

|

|

|

|

| |||

|

|

|

|

| ||

|

|

|

| |||

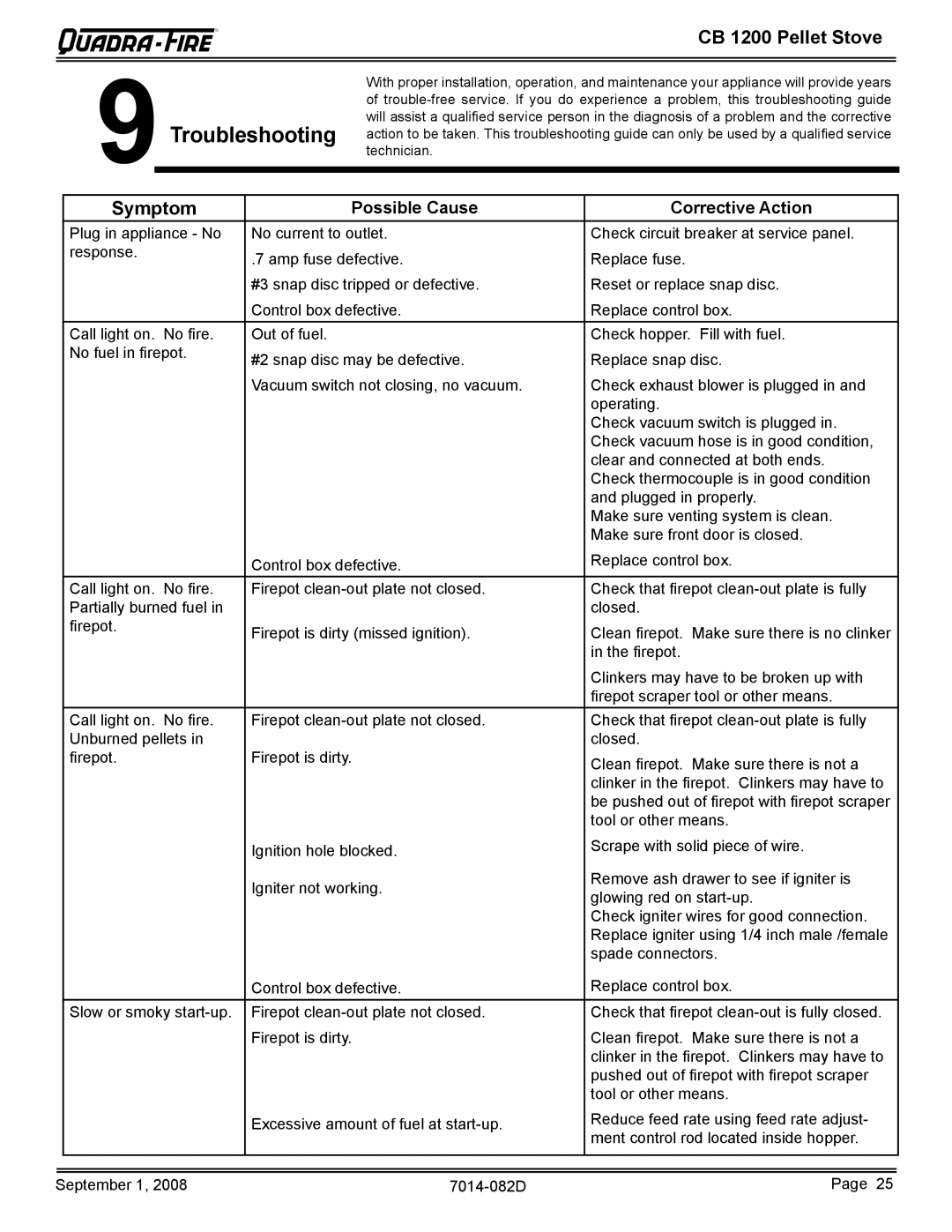

| Symptom | Possible Cause | Corrective Action | |||

| Plug in appliance - No | No current to outlet. | Check circuit breaker at service panel. | |||

| response. |

| .7 amp fuse defective. | Replace fuse. | ||

|

|

|

| |||

|

|

|

| #3 snap disc tripped or defective. | Reset or replace snap disc. | |

|

|

|

| Control box defective. | Replace control box. | |

| Call light on. No fire. | Out of fuel. |

| Check hopper. Fill with fuel. | ||

| No fuel in firepot. | #2 snap disc may be defective. | Replace snap disc. | |||

|

|

|

| |||

|

|

|

| Vacuum switch not closing, no vacuum. | Check exhaust blower is plugged in and | |

|

|

|

|

|

| operating. |

|

|

|

|

|

| Check vacuum switch is plugged in. |

|

|

|

|

|

| Check vacuum hose is in good condition, |

|

|

|

|

|

| clear and connected at both ends. |

|

|

|

|

|

| Check thermocouple is in good condition |

|

|

|

|

|

| and plugged in properly. |

|

|

|

|

|

| Make sure venting system is clean. |

|

|

|

|

|

| Make sure front door is closed. |

|

|

|

| Control box defective. | Replace control box. | |

| Call light on. No fire. | Firepot | Check that firepot | |||

| Partially burned fuel in |

|

| closed. | ||

| firepot. |

| Firepot is dirty (missed ignition). | Clean firepot. Make sure there is no clinker | ||

|

|

|

| |||

|

|

|

|

|

| in the firepot. |

|

|

|

|

|

| Clinkers may have to be broken up with |

|

|

|

|

|

| firepot scraper tool or other means. |

| Call light on. No fire. | Firepot | Check that firepot | |||

| Unburned pellets in |

|

| closed. | ||

| firepot. |

| Firepot is dirty. |

| Clean firepot. Make sure there is not a | |

|

|

|

|

|

| |

|

|

|

|

|

| clinker in the firepot. Clinkers may have to |

|

|

|

|

|

| be pushed out of firepot with firepot scraper |

|

|

|

|

|

| tool or other means. |

|

|

|

| Ignition hole blocked. | Scrape with solid piece of wire. | |

|

|

|

| Igniter not working. | Remove ash drawer to see if igniter is | |

|

|

|

| glowing red on | ||

|

|

|

|

|

| |

|

|

|

|

|

| Check igniter wires for good connection. |

|

|

|

|

|

| Replace igniter using 1/4 inch male /female |

|

|

|

|

|

| spade connectors. |

|

|

|

| Control box defective. | Replace control box. | |

| Slow or smoky | Firepot | Check that firepot | |||

|

|

|

| Firepot is dirty. |

| Clean firepot. Make sure there is not a |

|

|

|

|

|

| clinker in the firepot. Clinkers may have to |

|

|

|

|

|

| pushed out of firepot with firepot scraper |

|

|

|

|

|

| tool or other means. |

|

|

|

| Excessive amount of fuel at | Reduce feed rate using feed rate adjust- | |

|

|

|

|

|

| ment control rod located inside hopper. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

September 1, 2008 | Page 25 |