SERVICING PROCEDURES

TUBE CLEANING PROCEDURE (TYPICAL)

Establish a regular inspection schedule, the fre- quency depending on the local water condition and severity of service. Do not let the tubes clog up solidly. Clean out deposits over 1/16" in thickness.

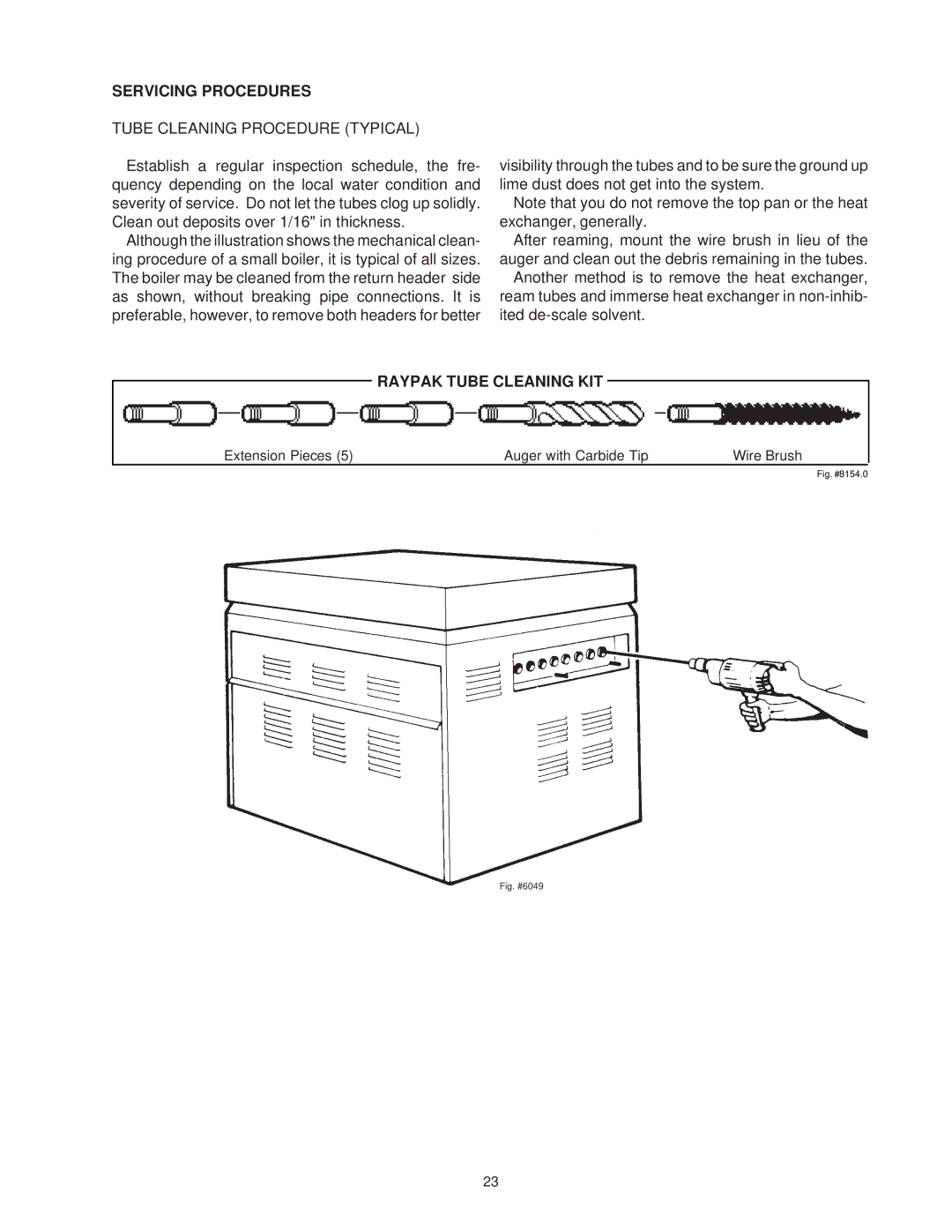

Although the illustration shows the mechanical clean- ing procedure of a small boiler, it is typical of all sizes. The boiler may be cleaned from the return header side as shown, without breaking pipe connections. It is preferable, however, to remove both headers for better

visibility through the tubes and to be sure the ground up lime dust does not get into the system.

Note that you do not remove the top pan or the heat exchanger, generally.

After reaming, mount the wire brush in lieu of the auger and clean out the debris remaining in the tubes.

Another method is to remove the heat exchanger, ream tubes and immerse heat exchanger in

RAYPAK TUBE CLEANING KIT

Extension Pieces (5) | Auger with Carbide Tip | Wire Brush |

Fig. #8154.0

Fig. #6049

23