DANGER: There is a Hot Water SCALD Potential if the tankstat is set too high.

CAUTION: Hotter water increases the risk of

SCALDING!

NOTE: When this heater is supplying general purpose hot water requirements for use by individuals, a thermostatically controlled mixing valve for reducing point of use water temperature is recommended to reduce the risk of scald injury. Contact a licensed plumber or the local plumbing authority for further information.

RECEIVING EQUIPMENT

On receipt of your equipment it is suggested that you visually check for external damage to the carton. If the carton is damaged, it is suggested that a note be made on the Bill of Lading when signing for equipment. Remove the heater from the carton and if it is dam- aged report the damage to the carrier immediately. Be sure that you receive the number of packages indicat- ed on the Bill of Lading. Claims for shortages and damages must be filed with carrier by consignee.

Purchased parts are subject to replacement only under the manufacturer's warranty. Debits for defec- tive replacement parts will not be accepted and defective parts will be replaced in kind only per our standard warranties.

When ordering parts, you must specify Model and Serial Number of the heater. When ordering under

warranty conditions, you must also specify date of installation.

Raypak recommends that this manual be reviewed thoroughly before installing your Raypak heater. If there are any questions which this manual does not answer, please contact your local Raypak representa- tive.

GENERAL

SPECIFICATIONS

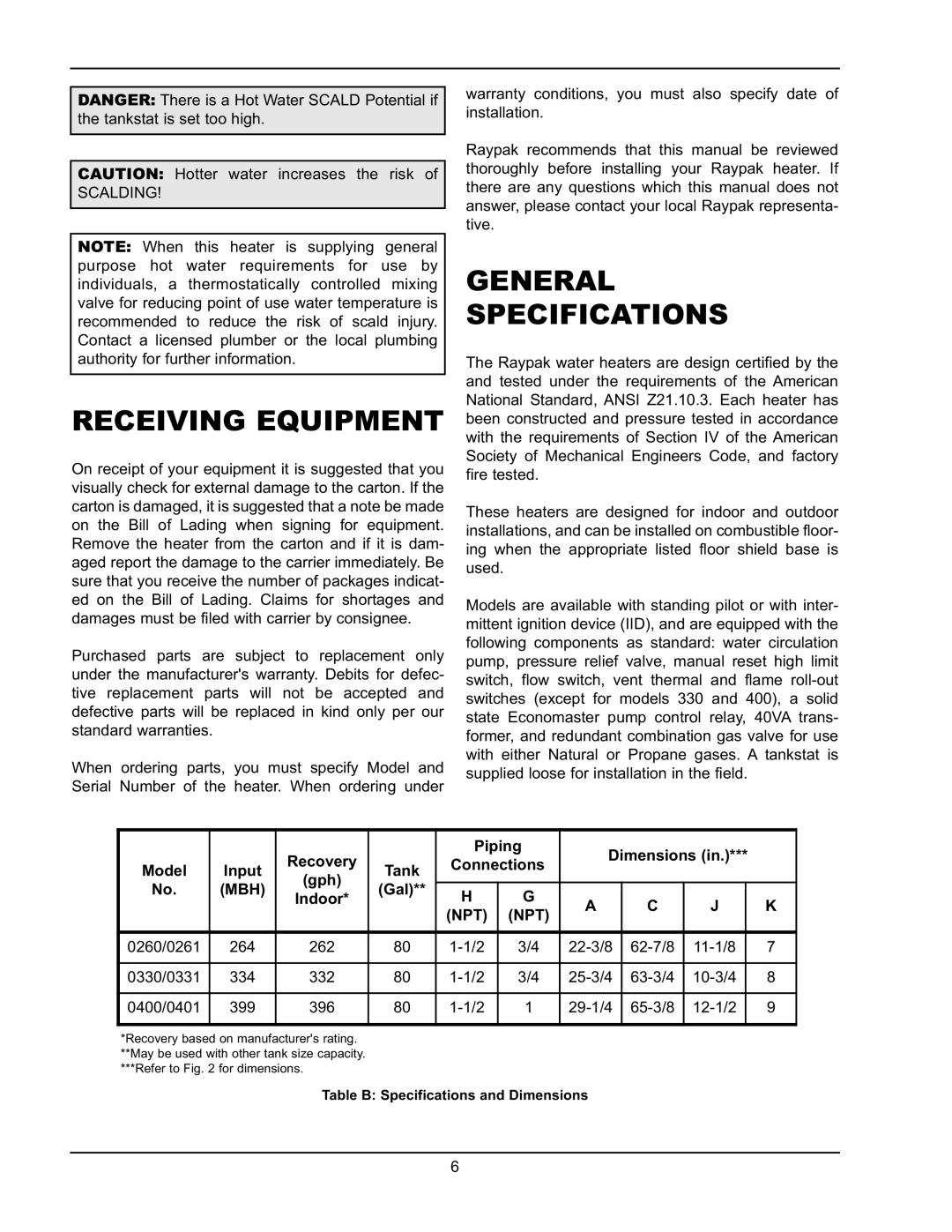

The Raypak water heaters are design certified by the and tested under the requirements of the American National Standard, ANSI Z21.10.3. Each heater has been constructed and pressure tested in accordance with the requirements of Section IV of the American Society of Mechanical Engineers Code, and factory fire tested.

These heaters are designed for indoor and outdoor installations, and can be installed on combustible floor- ing when the appropriate listed floor shield base is used.

Models are available with standing pilot or with inter- mittent ignition device (IID), and are equipped with the following components as standard: water circulation pump, pressure relief valve, manual reset high limit switch, flow switch, vent thermal and flame

|

|

|

| Piping | Dimensions (in.)*** |

| ||||

|

| Recovery |

| Connections |

| |||||

Model | Input | Tank |

|

|

|

|

| |||

(gph) |

|

|

|

|

|

|

| |||

No. | (MBH) | (Gal)** |

|

|

|

|

|

|

| |

H | G |

|

|

|

|

| ||||

Indoor* |

|

|

|

|

| |||||

|

|

| A | C | J |

| K | |||

|

|

|

| (NPT) | (NPT) |

| ||||

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

0260/0261 | 264 | 262 | 80 | 3/4 |

| 7 | ||||

|

|

|

|

|

|

|

|

|

|

|

0330/0331 | 334 | 332 | 80 | 3/4 |

| 8 | ||||

|

|

|

|

|

|

|

|

|

|

|

0400/0401 | 399 | 396 | 80 | 1 |

| 9 | ||||

|

|

|

|

|

|

|

|

|

|

|

*Recovery based on manufacturer's rating. **May be used with other tank size capacity.

***Refer to Fig. 2 for dimensions.

Table B: Specifications and Dimensions

6