ASSEMBLY

Continued

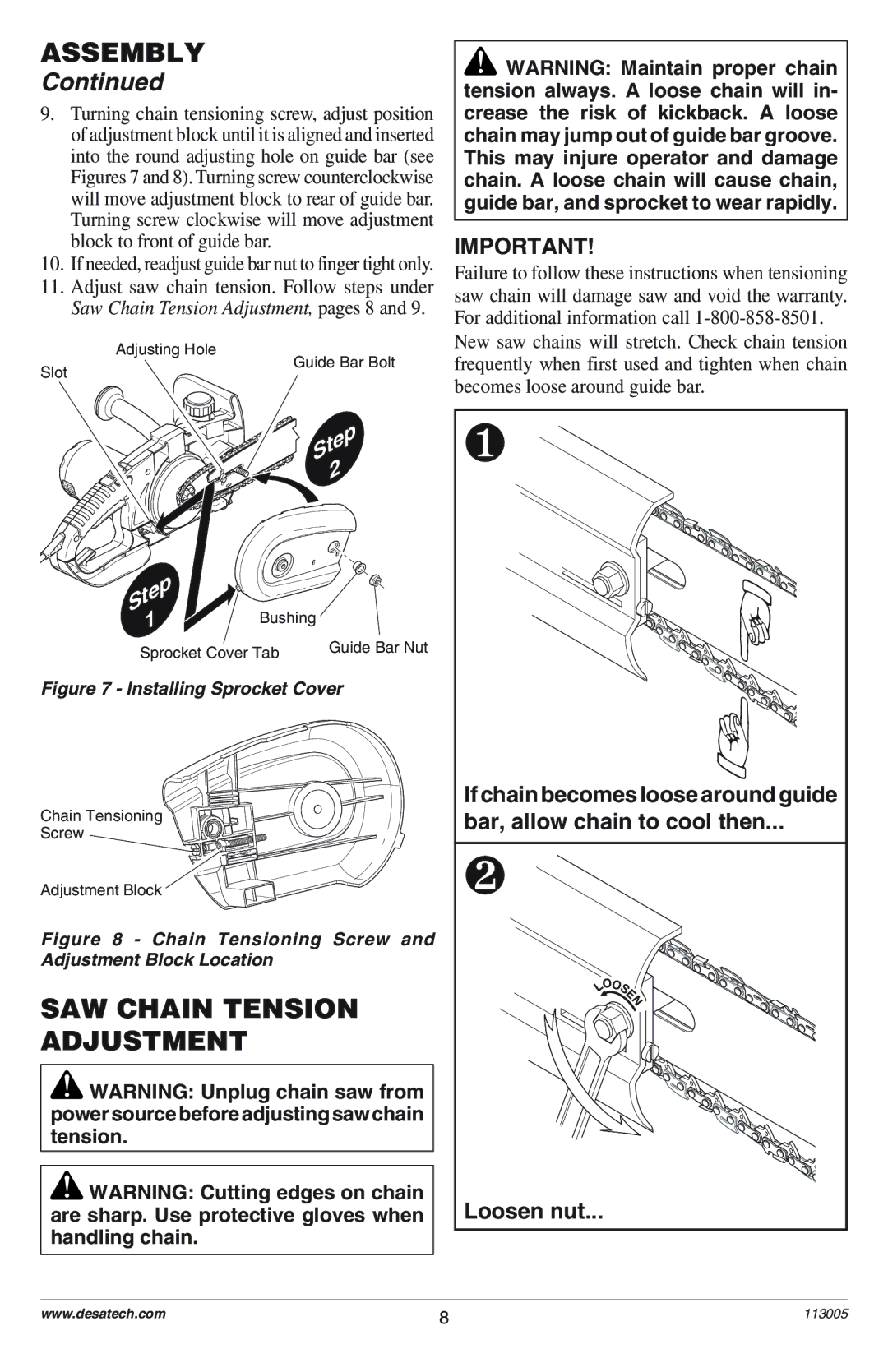

9.Turning chain tensioning screw, adjust position of adjustment block until it is aligned and inserted into the round adjusting hole on guide bar (see Figures 7 and 8). Turning screw counterclockwise will move adjustment block to rear of guide bar. Turning screw clockwise will move adjustment block to front of guide bar.

10.If needed, readjust guide bar nut to finger tight only.

11.Adjust saw chain tension. Follow steps under Saw Chain Tension Adjustment, pages 8 and 9.

Adjusting Hole

![]() WARNING: Maintain proper chain tension always. A loose chain will in- crease the risk of kickback. A loose chain may jump out of guide bar groove. This may injure operator and damage chain. A loose chain will cause chain, guide bar, and sprocket to wear rapidly.

WARNING: Maintain proper chain tension always. A loose chain will in- crease the risk of kickback. A loose chain may jump out of guide bar groove. This may injure operator and damage chain. A loose chain will cause chain, guide bar, and sprocket to wear rapidly.

IMPORTANT!

Failure to follow these instructions when tensioning saw chain will damage saw and void the warranty. For additional information call

New saw chains will stretch. Check chain tension

Slot

Guide Bar Bolt

frequently when first used and tighten when chain becomes loose around guide bar.

Step |

2 |

Step | Bushing | |

1 | ||

|

Sprocket Cover Tab | Guide Bar Nut |

|

Figure 7 - Installing Sprocket Cover

Chain Tensioning

Screw

Adjustment Block

Figure 8 - Chain Tensioning Screw and Adjustment Block Location

SAW CHAIN TENSION ADJUSTMENT

![]() WARNING: Unplug chain saw from power source before adjusting saw chain tension.

WARNING: Unplug chain saw from power source before adjusting saw chain tension.

![]() WARNING: Cutting edges on chain are sharp. Use protective gloves when handling chain.

WARNING: Cutting edges on chain are sharp. Use protective gloves when handling chain.

❶

If chain becomes loose around guide

bar, allow chain to cool then...

❷

| O | |

O | S | |

L |

| |

|

| E |

|

| N |

Loosen nut...

www.desatech.com | 8 | 113005 |