MAINTENANCE

The actual speed at which the harmonic will occur will vary with each mower and each installation. To avoid this harmonic vibration when operating the mower, it may be necessary to adjust the engine speed of the tractor up or down.

Some units have a harmonic which occurs below the nominal operating speed. On these units, it will be noticed that there is always a little vibration at a particular RPM as the mower is being sped up to operating speed. This occurs as the shaft passes through its normal harmonic vibration point. As long as the mower is opened at the proper speed, then harmonic vibration will not be an issue.

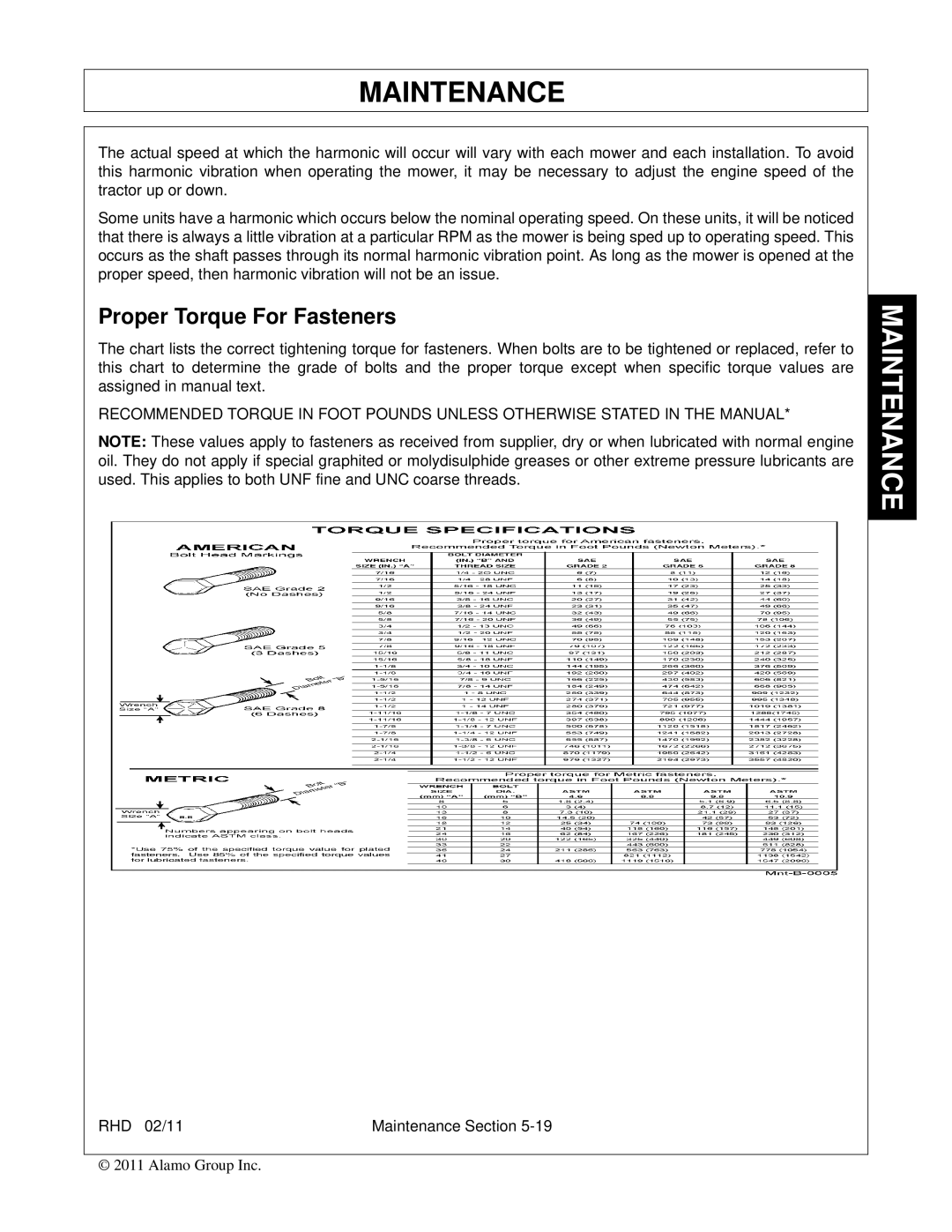

Proper Torque For Fasteners

The chart lists the correct tightening torque for fasteners. When bolts are to be tightened or replaced, refer to this chart to determine the grade of bolts and the proper torque except when specific torque values are assigned in manual text.

RECOMMENDED TORQUE IN FOOT POUNDS UNLESS OTHERWISE STATED IN THE MANUAL*

NOTE: These values apply to fasteners as received from supplier, dry or when lubricated with normal engine oil. They do not apply if special graphited or molydisulphide greases or other extreme pressure lubricants are used. This applies to both UNF fine and UNC coarse threads.

RHD 02/11 | Maintenance Section |

© 2011 Alamo Group Inc.