MAINTENANCE

MAINTENANCE

Cuttershaft Bearing Replacement

OUTBOARD (DRIVE) BEARING

1.Lift cutter unit to maximum horizontal height; then, securely support ends of cutterhousing.

2.Remove enough knives to place a floor jack under center of cuttershaft.

3.Securely support cuttershaft.

NOTE: The cuttershaft must remain supported while changing bearings.

4.Remove outboard

5.Remove fasteners securing bearing and housing assembly to cutterhousing; then remove bearing and housing assembly.

6.NOTE: There are two tapped holes in the housing which can be used to pull bearing and housing assembly out by using special tool No. 701627.

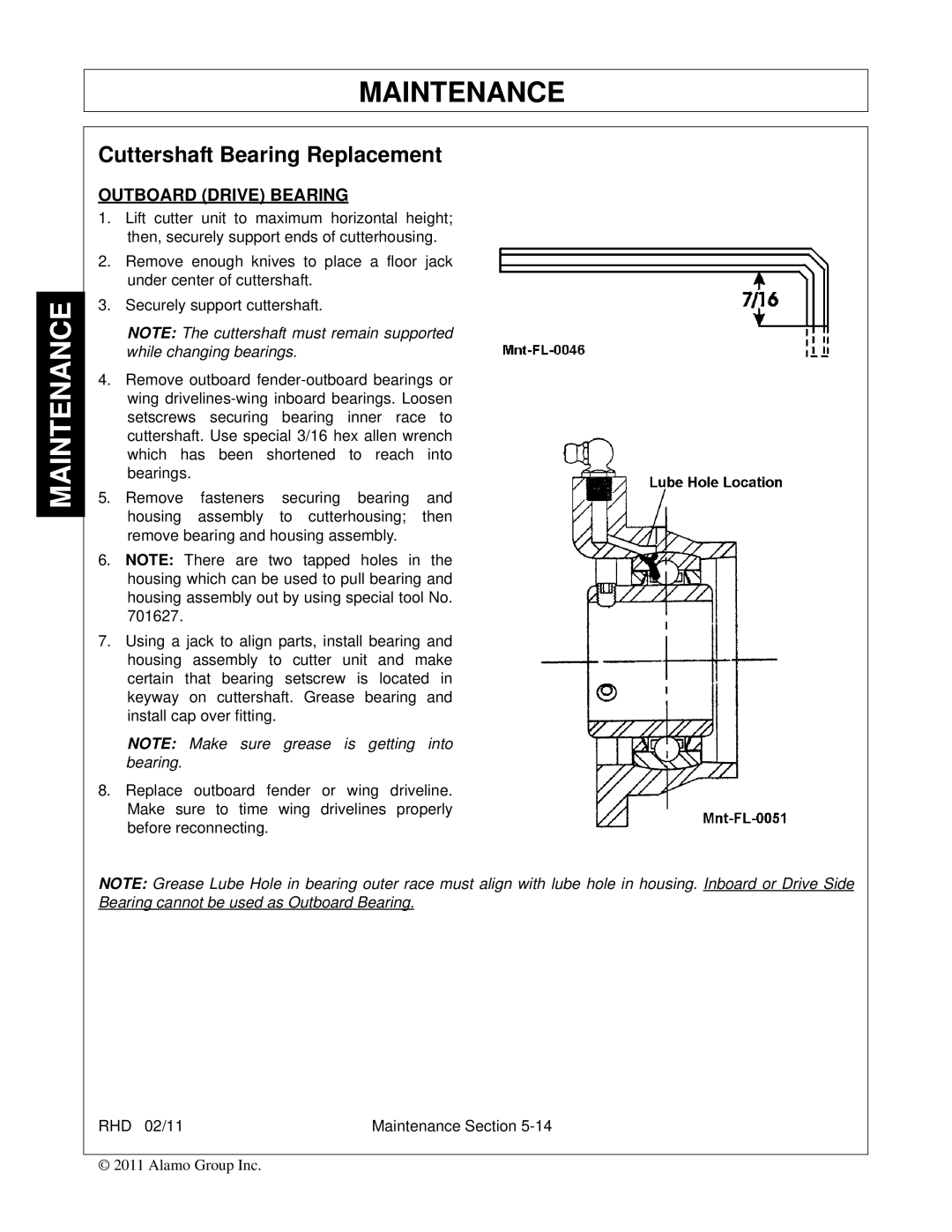

7.Using a jack to align parts, install bearing and housing assembly to cutter unit and make certain that bearing setscrew is located in keyway on cuttershaft. Grease bearing and install cap over fitting.

NOTE: Make sure grease is getting into bearing.

8.Replace outboard fender or wing driveline. Make sure to time wing drivelines properly before reconnecting.

NOTE: Grease Lube Hole in bearing outer race must align with lube hole in housing. Inboard or Drive Side Bearing cannot be used as Outboard Bearing.

RHD 02/11 | Maintenance Section |

© 2011 Alamo Group Inc.