258/258XL Power Pipe Cutters

Special Procedures

Adjusting Pivot Arm for Correct Pipe Size (258 Only)

1.The 258 is designed to cut pipe from 21/2″ through 8″ in diameter. The pivot arm holding the cutter wheel must be adjusted depending upon the size of the

pipe being cut. The 258 is shipped from the factory with the pivot arm positioned for 21/2″ through 4″ pipe cutting. To set the cutter for 6″ through 8″ diam- eter pipes, do the following:

Hitch Pin

Hairpin Cotter

Figure 9 – Removing Hairpin Cotter and Hitch Pin

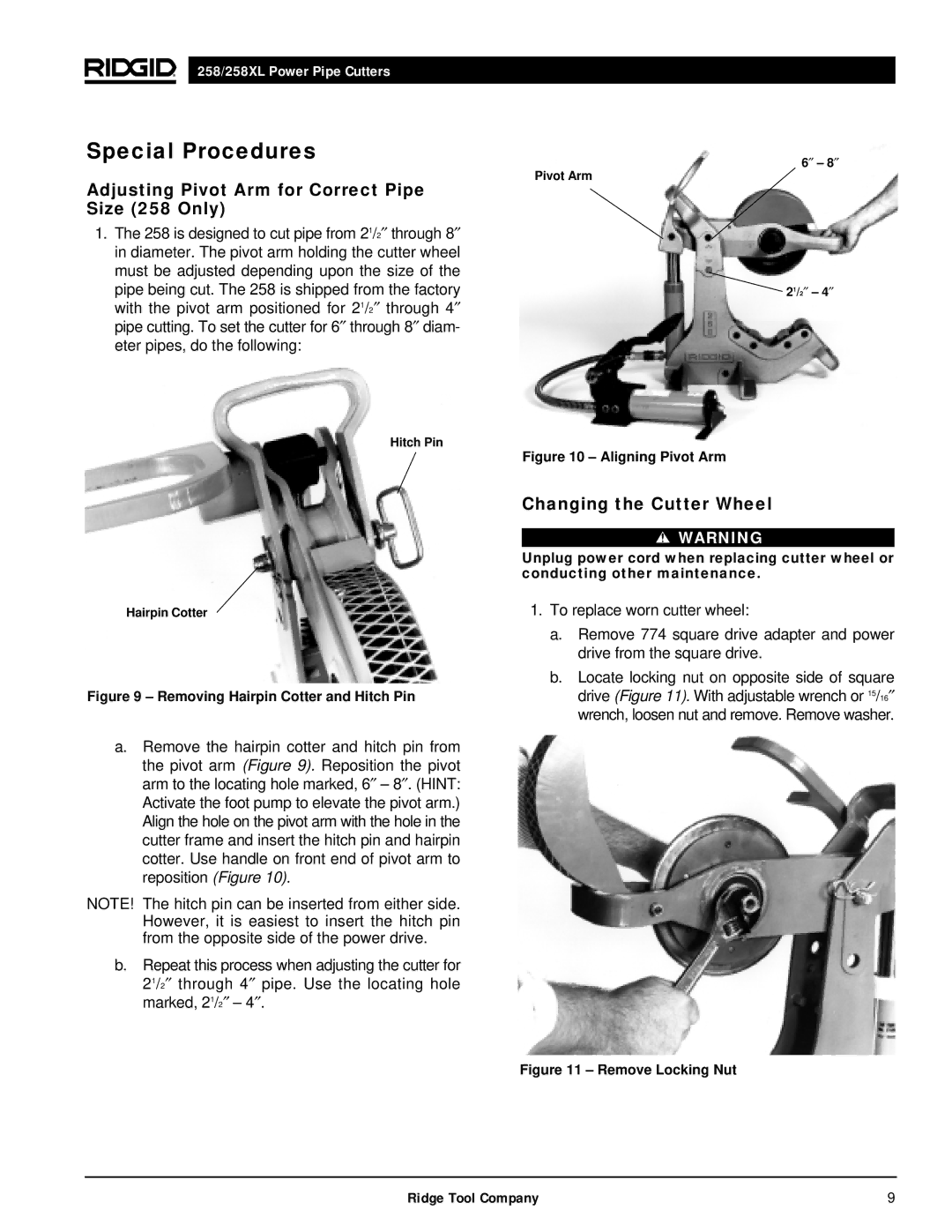

a.Remove the hairpin cotter and hitch pin from

the pivot arm (Figure 9). Reposition the pivot arm to the locating hole marked, 6″ – 8″ . (HINT: Activate the foot pump to elevate the pivot arm.) Align the hole on the pivot arm with the hole in the cutter frame and insert the hitch pin and hairpin cotter. Use handle on front end of pivot arm to reposition (Figure 10).

NOTE! The hitch pin can be inserted from either side. However, it is easiest to insert the hitch pin from the opposite side of the power drive.

b.Repeat this process when adjusting the cutter for 21/2″ through 4″ pipe. Use the locating hole marked, 21/2″ – 4″ .

6″ – 8″

Pivot Arm

21/2″ – 4″

Figure 10 – Aligning Pivot Arm

Changing the Cutter Wheel

![]() WARNING

WARNING

Unplug power cord when replacing cutter wheel or conducting other maintenance.

1.To replace worn cutter wheel:

a.Remove 774 square drive adapter and power drive from the square drive.

b.Locate locking nut on opposite side of square drive (Figure 11). With adjustable wrench or 15/16″ wrench, loosen nut and remove. Remove washer.

Figure 11 – Remove Locking Nut

Ridge Tool Company | 9 |